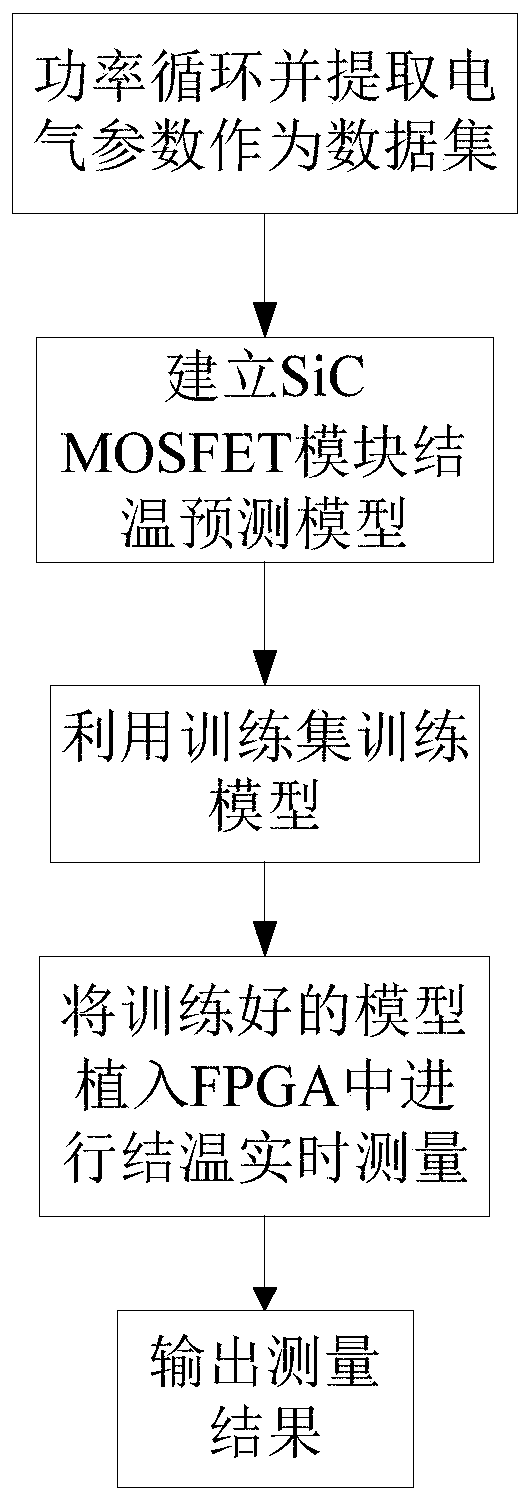

SiC MOSFET module full-life-cycle junction temperature online prediction method

A technology of whole life cycle and prediction method, applied in the field of online prediction of junction temperature in the whole life cycle of SiCMOSFET modules, can solve the problem of inaccurate junction temperature prediction results, achieve strong self-learning and self-adaptive ability, and overcome the effect of over-temperature protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

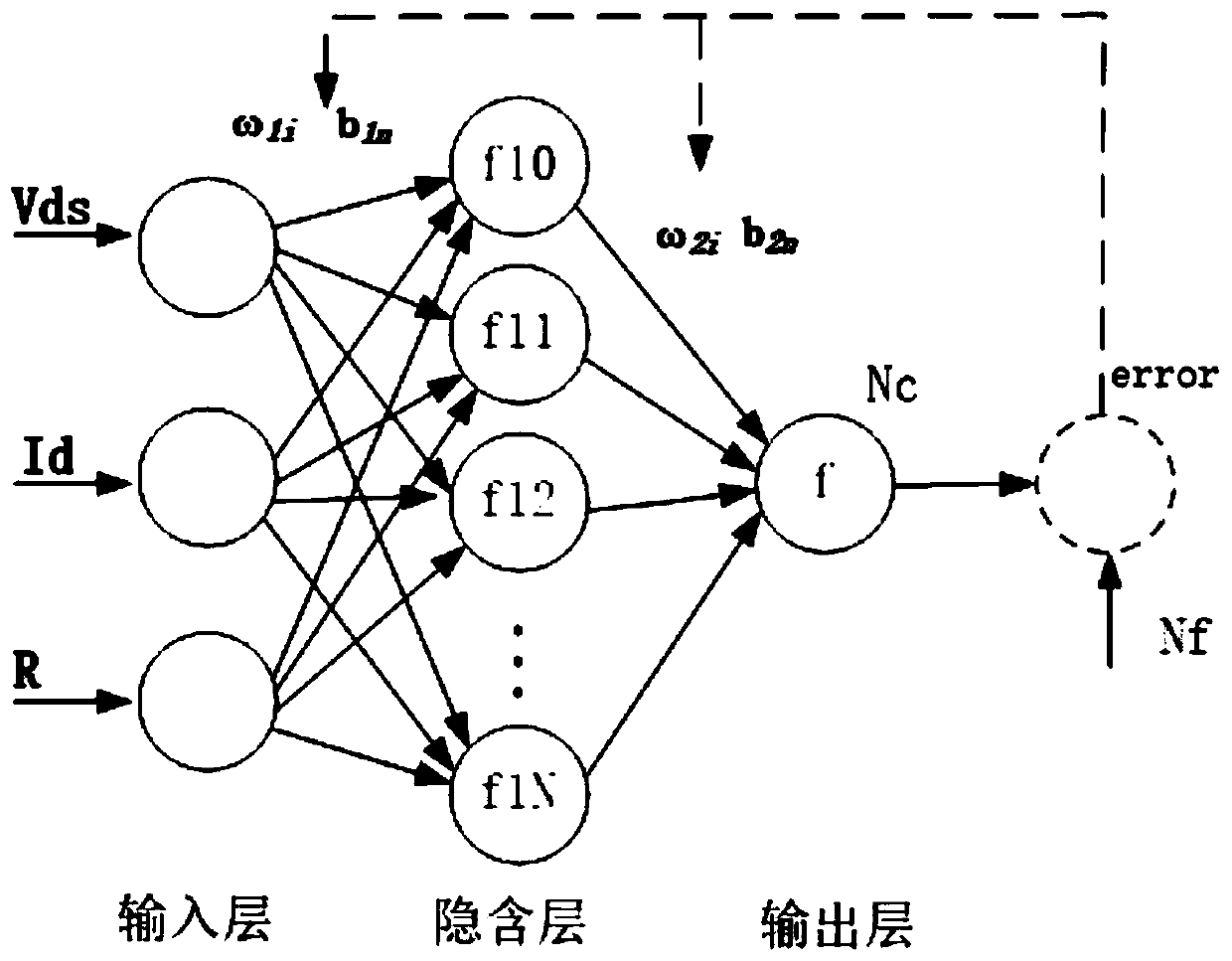

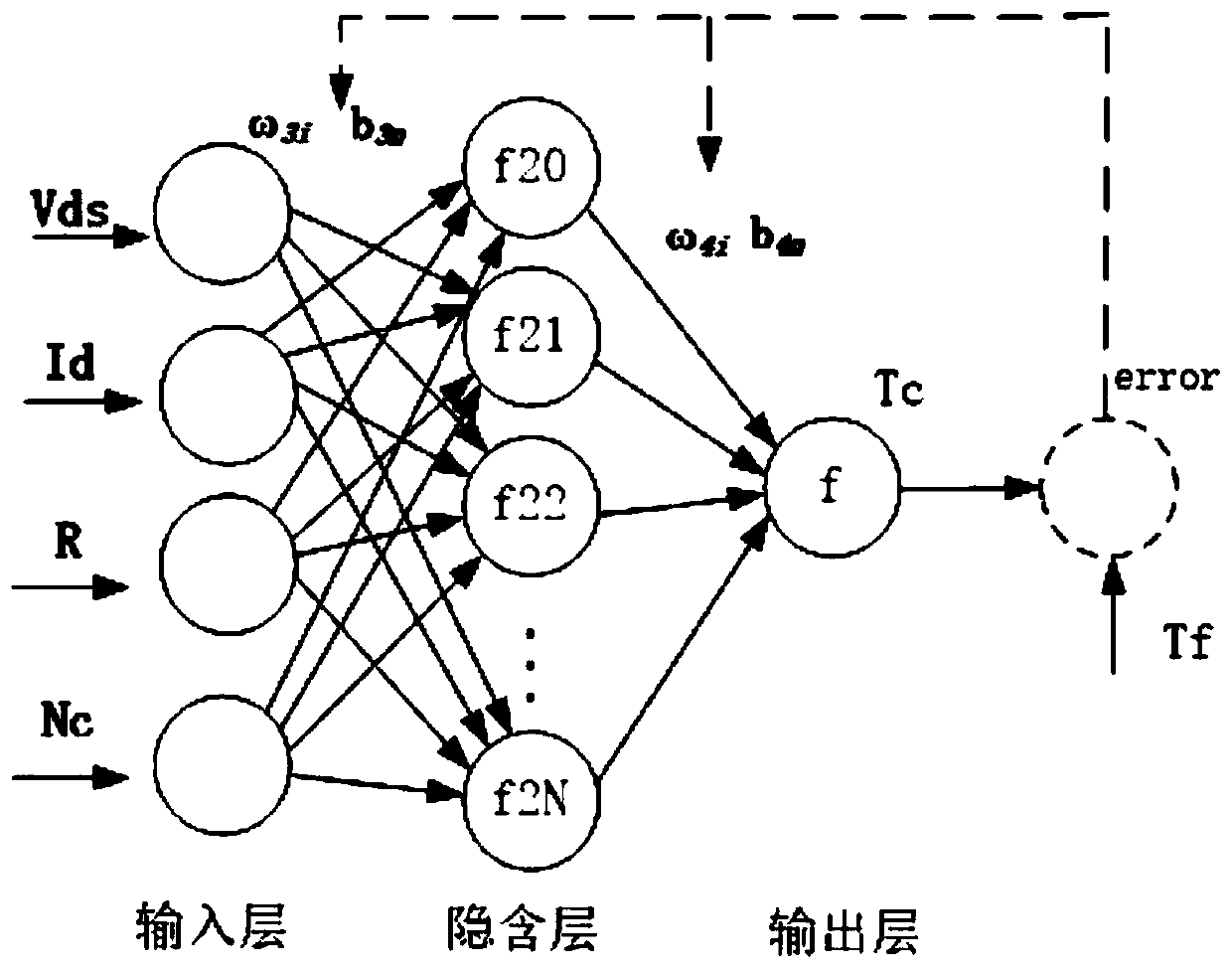

[0031] Step 1. For the 1200V / 300A model BSM300D12P2E001 produced by Rohm, a brand-new SiC MOSFET module, perform a power cycle until the module is completely aging and fails; during the power cycle, the electrical parameters of the SiC MOSFET module are sampled as a data set, and the electrical parameters are respectively Vds, Id and R, where Vds is the saturation voltage drop, Id is the current value, and R is the resistance value;

[0032] The specific sampling method is:

[0033] The current value Id of the DC power supply is set, and the DC value is randomly selected within the range of [1,150]. The junction temperature starts from 30°C, and the electrical parameters are obtained by sampling at intervals. The sampling frequency is 2000 power cycles at the initial aging stage. In the later stage of aging, the power cycle is 1000 times, and the sampling data is divided into training group data and test group data according to 3:1; the training group is used as a data set, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com