Lithium battery allowing internal temperature and pressure to be detected

An internal temperature, lithium battery technology, used in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problem of not being able to detect abnormalities in time, and achieve the effect of reducing detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

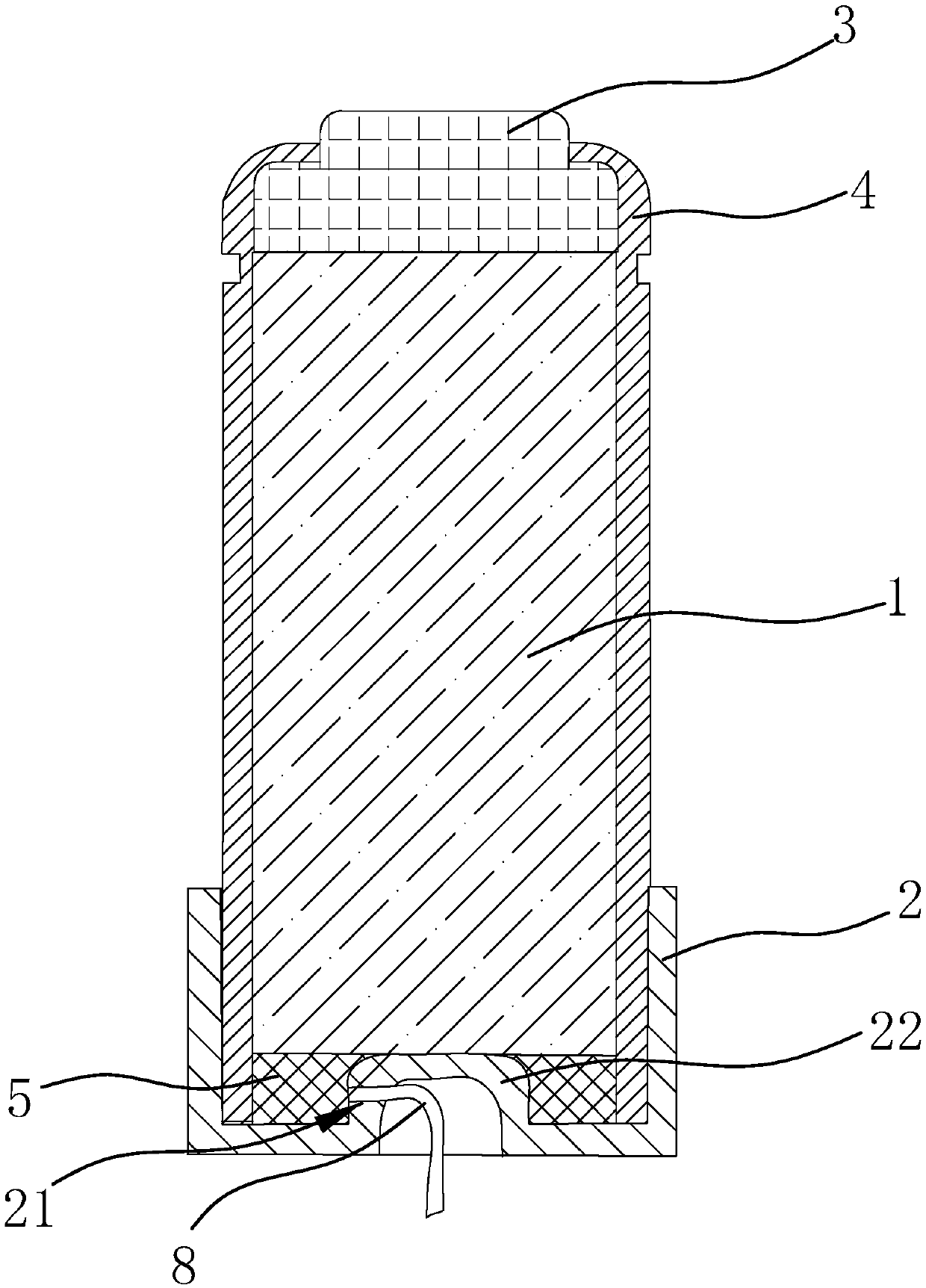

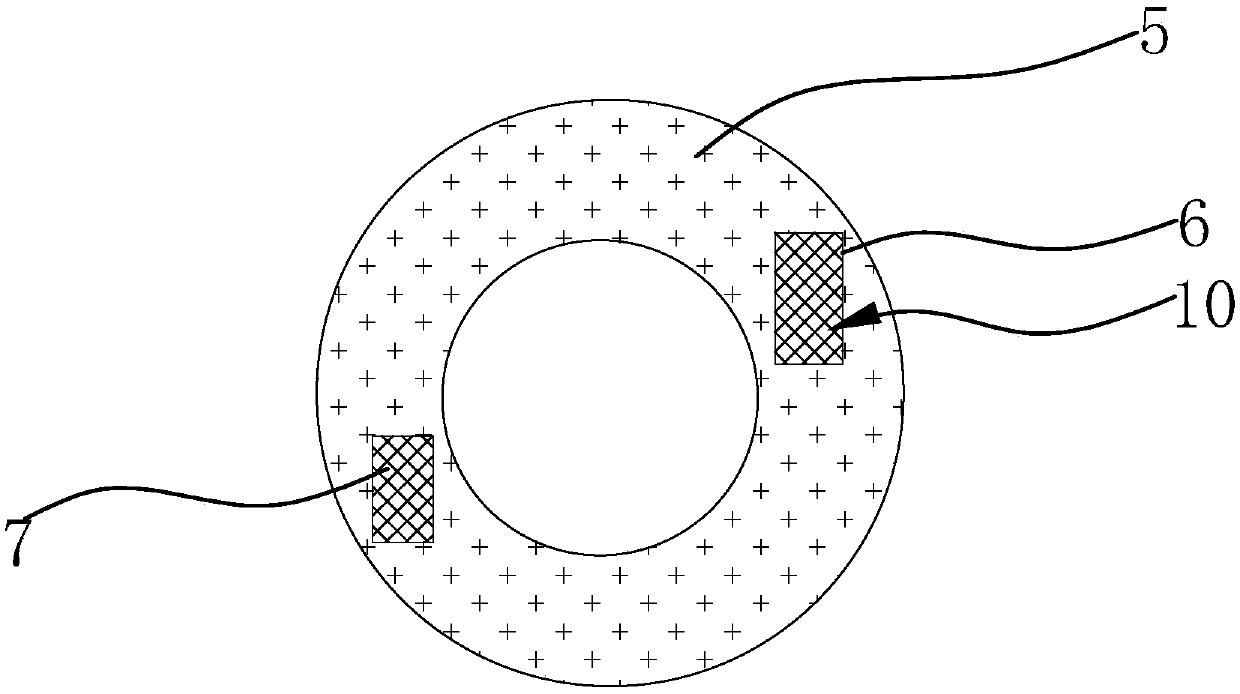

[0029] Such as figure 1 and figure 2 As shown, the lithium battery includes a cell 1, a base 2, a cap 3 and a cylindrical casing 4, the base 2 is fixed at the lower end of the casing 4, the cap 3 is fixed at the upper end of the casing 4, and the cell 1 is inserted into the Located in the housing 4, the bottom of the base 2 is provided with a PCB board 5, and the side of the PCB board 5 facing the interior of the housing 4 is respectively provided with a temperature sensor 6 and a pressure sensor 7; the PCB board 5 is connected with a data transmission line 8, and the base 2 is provided with a through hole 21, and one end of the data transmission line 8 extends out of the housing 4 through the through hole 21. Further, the surface of the temperature sensor 6 is provided with a layer of insulating and heat-conducting film 10, the insulating and heat-conducting film 10 is attached to the end surface of the battery cell 1, the middle part of the base 2 is recessed into the hous...

Embodiment 2

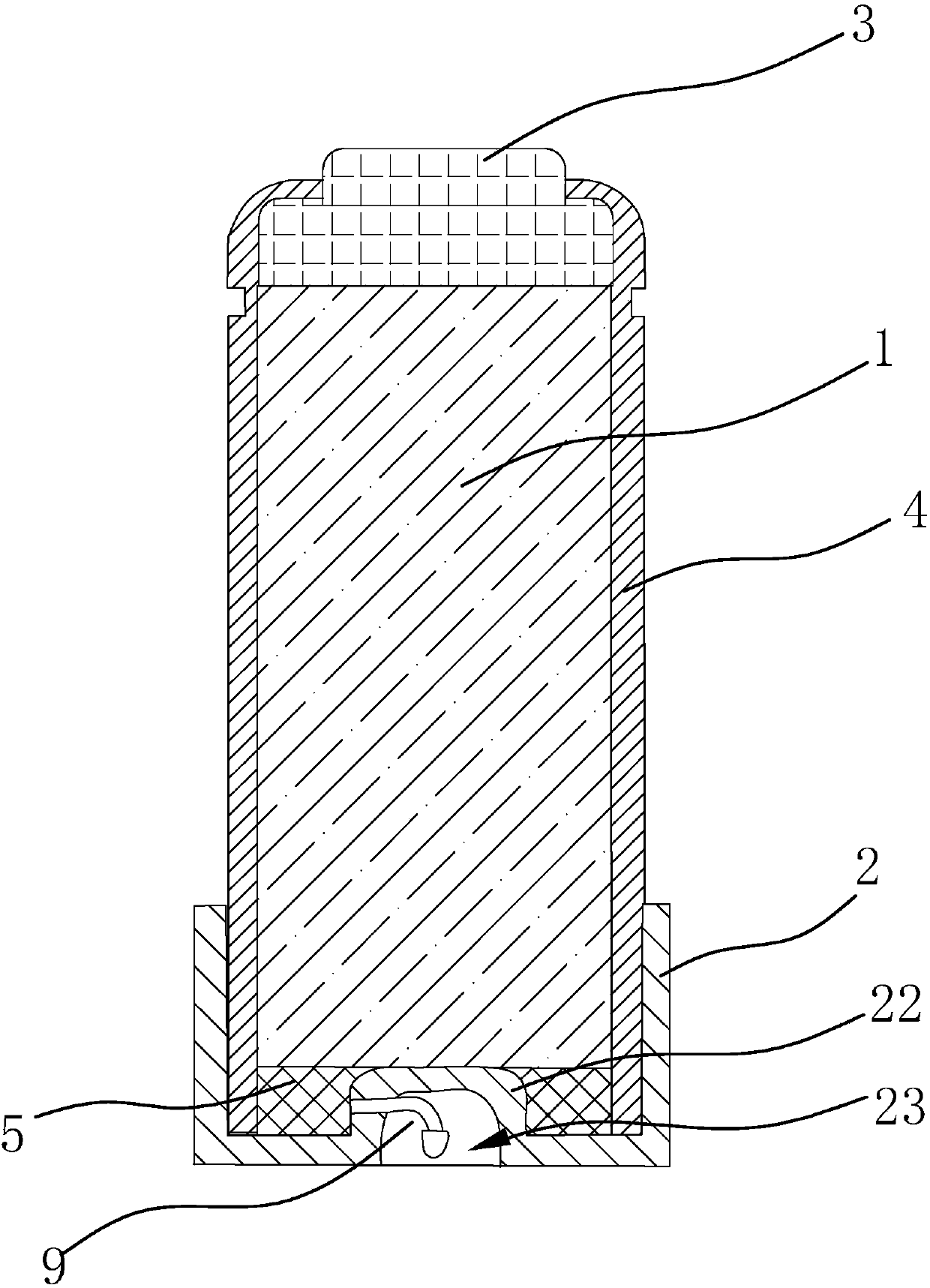

[0034] Such as image 3 and Figure 4 As shown, the lithium battery includes a cell 1, a base 2, a cap 3 and a cylindrical casing 4, the base 2 is fixed at the lower end of the casing 4, the cap 3 is fixed at the upper end of the casing 4, and the cell 1 is inserted into the Set in the housing 4, the bottom of the base 2 is provided with a PCB board 5, and the side of the PCB board 5 facing the inside of the housing 4 is respectively provided with a temperature sensor 6 and a pressure sensor 7; a wireless data transmitter is also connected to the PCB board 5 9. The middle part of the base 2 is recessed into the housing 4 to form a boss 22, and the outward side of the boss 22 forms a concave cavity 23, the boss 22 is cylindrical, the PCB board 5 is ring-shaped, and the PCB board 5 is set on the Around the boss 22 , the wireless data transmitter 9 includes a chip wireless transmitting module 91 arranged on the PCB 5 and a wireless transmitting terminal 92 passing through the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com