Apparatus for realizing automatic butt joint of ox-horn-like plug and socket

An automatic docking, plug and socket technology, applied in the connection/disconnection of connection devices, vehicle connectors, etc., can solve the problems of difficulty in ensuring connection quality, operator danger, and difficulty, and achieve low initial position accuracy and modularity. High, holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

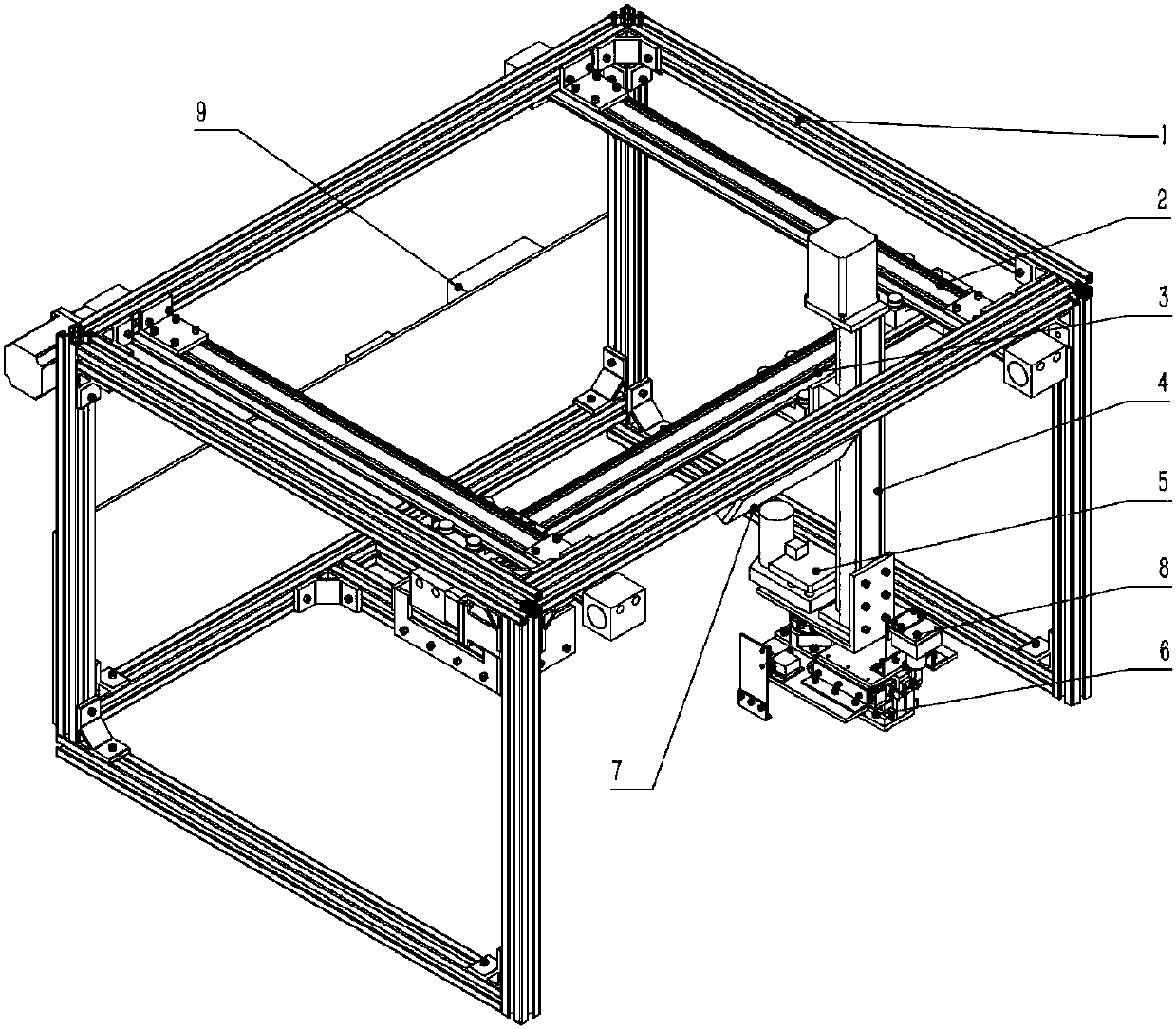

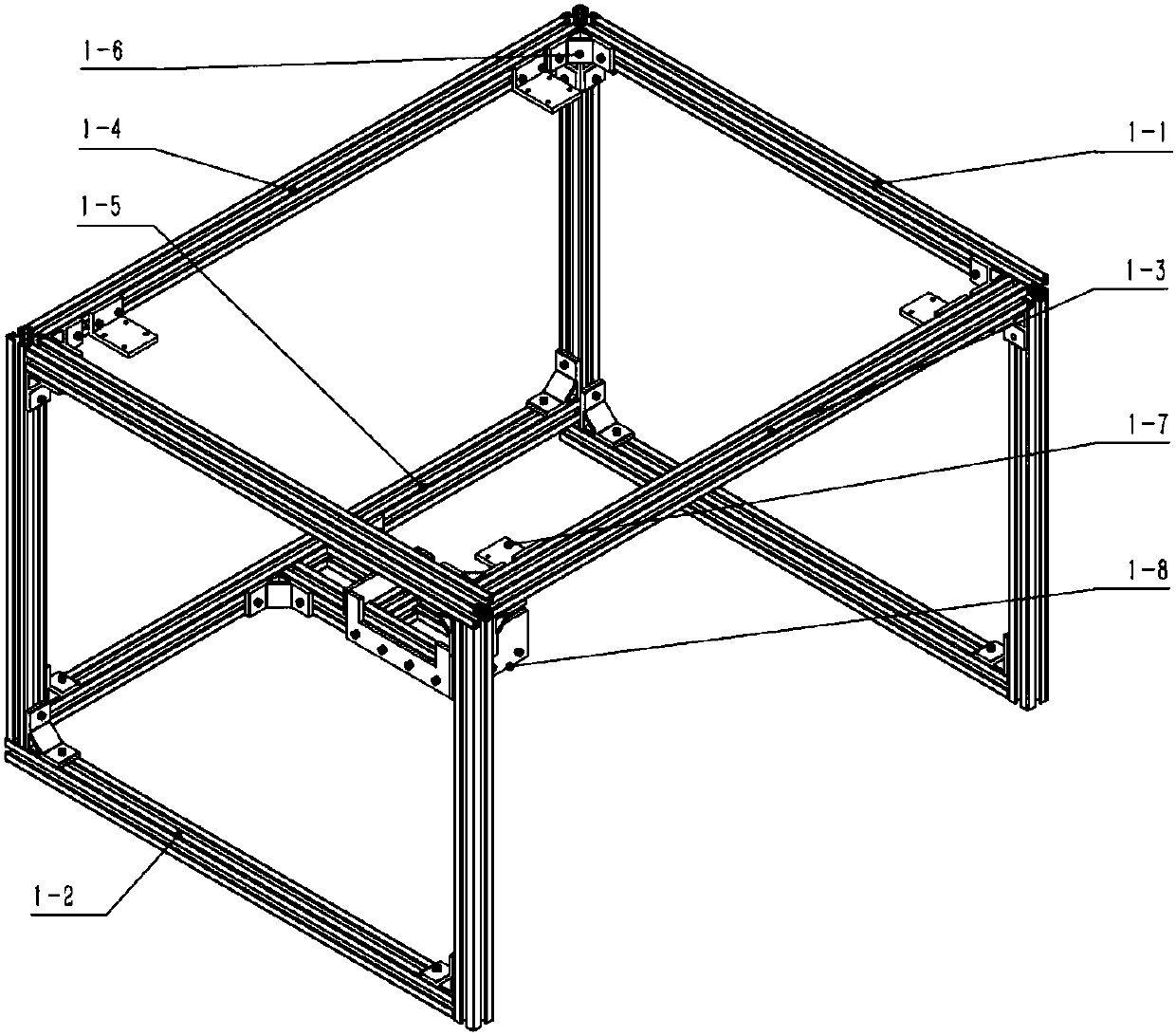

[0040] Such as figure 1 As shown, a preferred embodiment of the present invention provides a device for automatic docking of horn plugs and sockets, including a receiving platform 1, a first X-direction translation mechanism 2, a second X-direction translation mechanism, and a Y-direction translation mechanism. Mechanism 3, Z-direction translation mechanism 4, Z-direction rotation mechanism 5, horn plug cable grabbing device 6, global camera 7, local camera 8, control system 9;

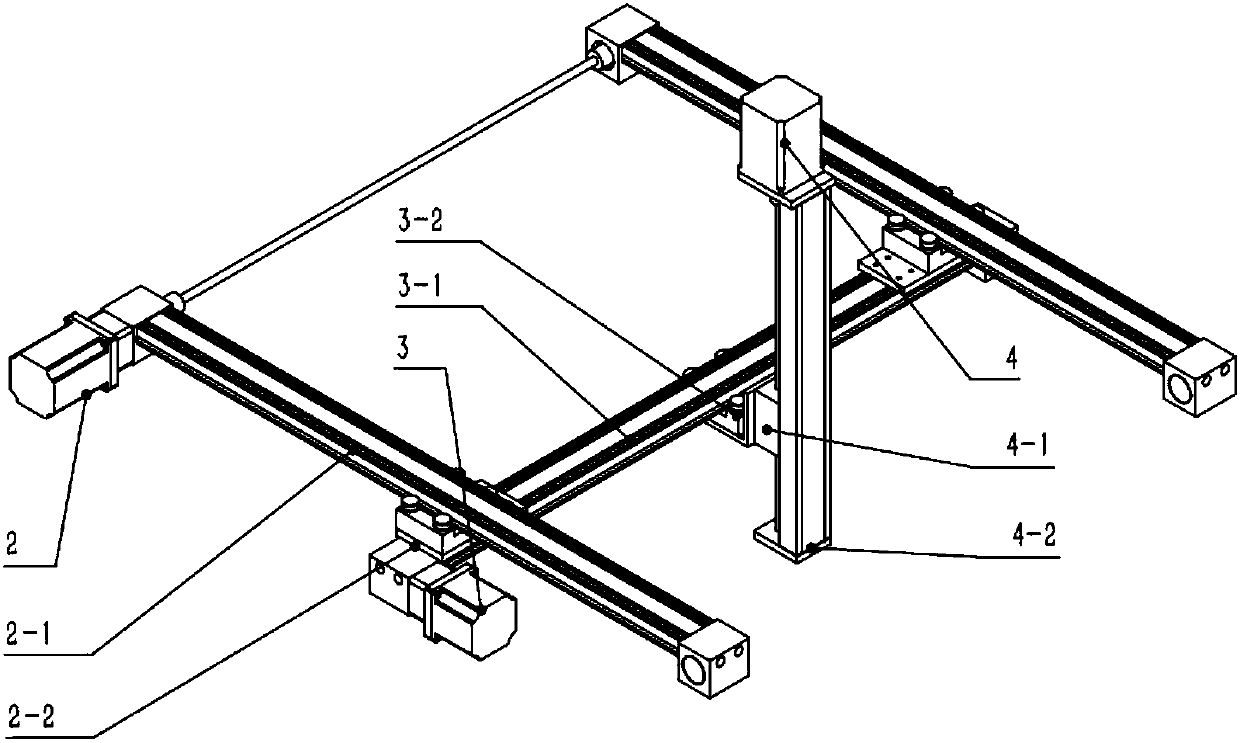

[0041] Wherein, the first X-direction translation mechanism 2 and the second X-direction translation mechanism are set to be installed on the receiving platform 1; the first X-direction translation mechanism 2 and the second X-direction translation mechanism are set to be parallel to each other;

[0042] The Y-direction translation mechanism 3 is arranged to be installed on the first X-direction translation mechanism 2 and the second X-direction translation mechanism, and is perpendicular to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com