Lily bulb sowing vehicle and seeder thereof

A kind of seeder and lily technology, which is applied to the parts of the seeder, the machine for interval quantitative sowing, and the planting method, etc. It can solve the problems of inconsistent artificial planting density, large volume of lily bulbs, and difficult management, so as to facilitate later management , Simple operation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

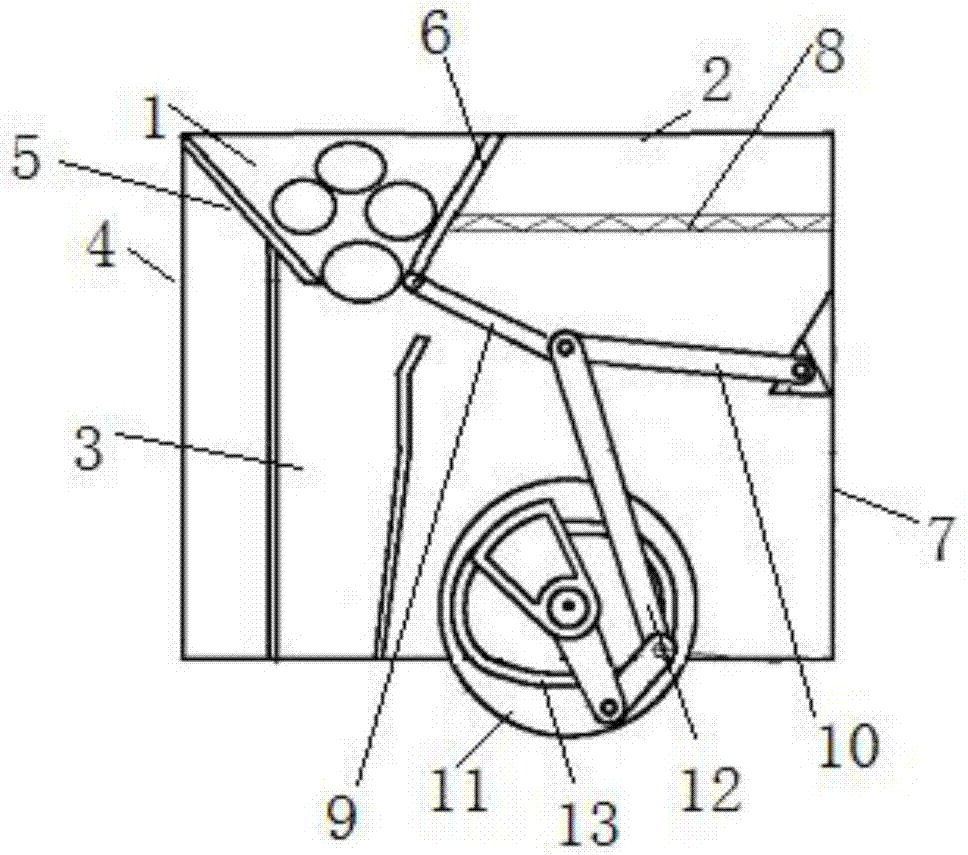

[0030] The invention provides a seeder, such as figure 1 As shown, it includes a frame 2 with a discharge port 1 installed on the top, and a lower end of the discharge port 1 is provided with a discharge pipe 3; the bottom of the frame 2 is open. The discharge port 1 includes a first slant plate 5 fixed on the top of the first side wall 4 of the frame 2 and a second slant plate 6 hinged on the top of the frame 2, the second slant plate 6 is connected to the top of the frame 2 A support spring 8 is connected between the second side walls 7 of the frame 2, a first connecting rod 9 is hinged at the end of the second inclined plate 6, and a second connecting rod 10 is hinged at the end of the first connecting rod 9, so The end of the second connecting rod 10 is hinged with the second side wall 7 of the frame through a triangular connection block; It is connected with one side of the roller 11 through a four-bar linkage mechanism 12 . The side surface of the roller 11 is provided...

Embodiment 2

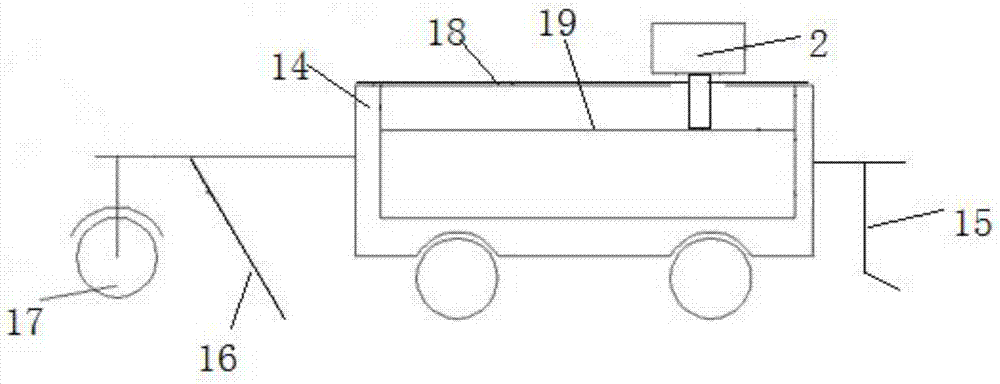

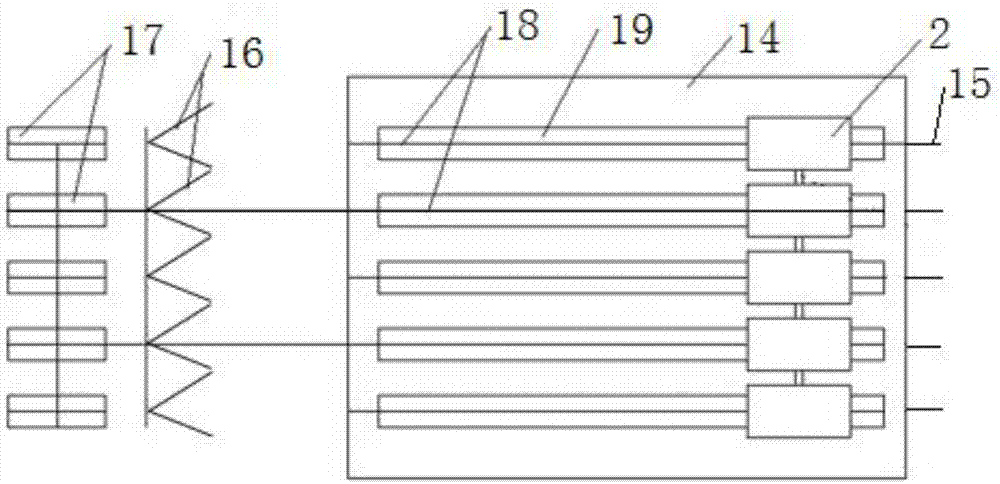

[0033] The present invention makes a further improvement on the basis of Embodiment 1, and provides a kind of lily bulb sowing vehicle that adopts the seeder described in Embodiment 1, such as Figure 2 to Figure 5 As shown, it includes a car body 14, the front end of the car body 14 is provided with a ditch opener 15, the rear end of the car body 14 is connected with a V-shaped soil covering plate 16 and a circular pressure wheel 17, and the rollers of the seeder 11 is movably installed on the vehicle body 14, and the bottom of the vehicle body 14 is open. Described car body 14 is provided with slide rail 18 and V-shaped device 19, and the roller 11 of described sower is positioned on described slide rail 18, and described feeding pipe 3 is positioned at described V-shaped device 19 just above; The middle part of the two side plates of the V-shaped device 19 is movably connected by a fixed rod 20, and the top of the two side plates of the V-shaped device 19 is connected by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com