Heel tendon suture assembly

A technology of components and suture needles, which is applied in the field of orthopedic instruments, can solve problems such as uneven force on sutures and poor suture strength, and achieve the effect of improving strength and reducing surgical injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

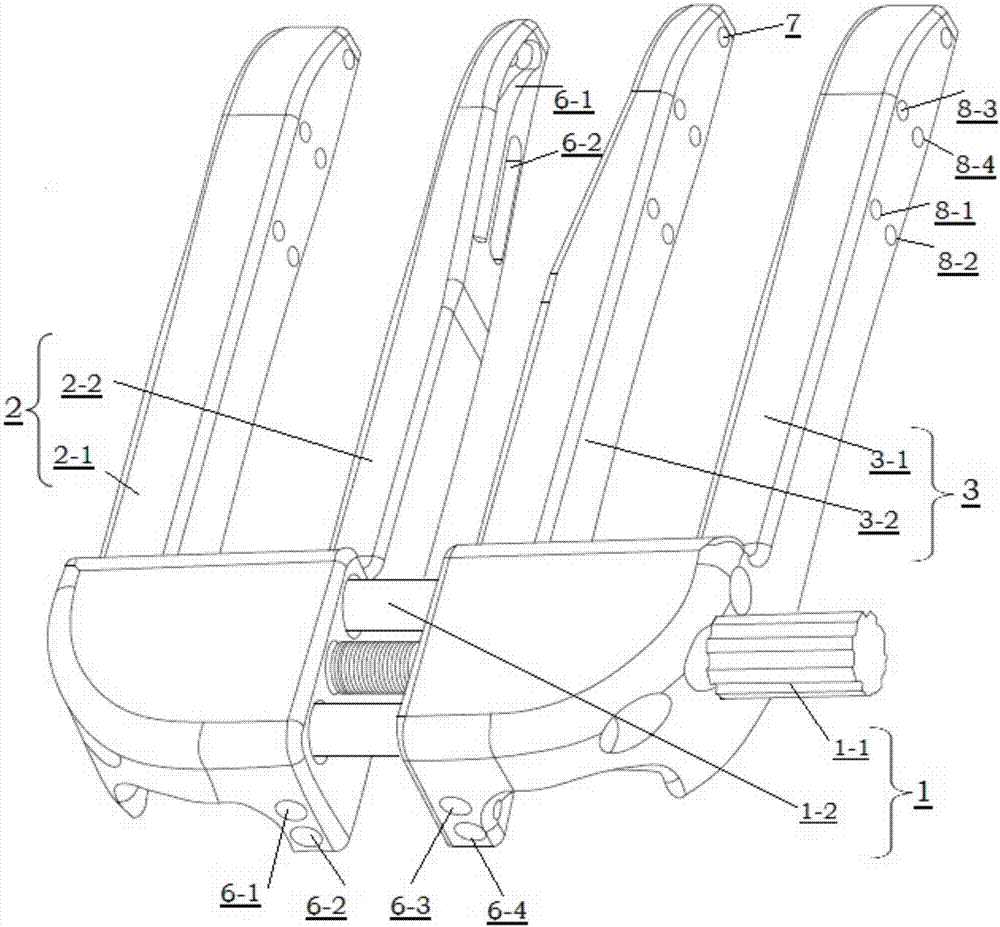

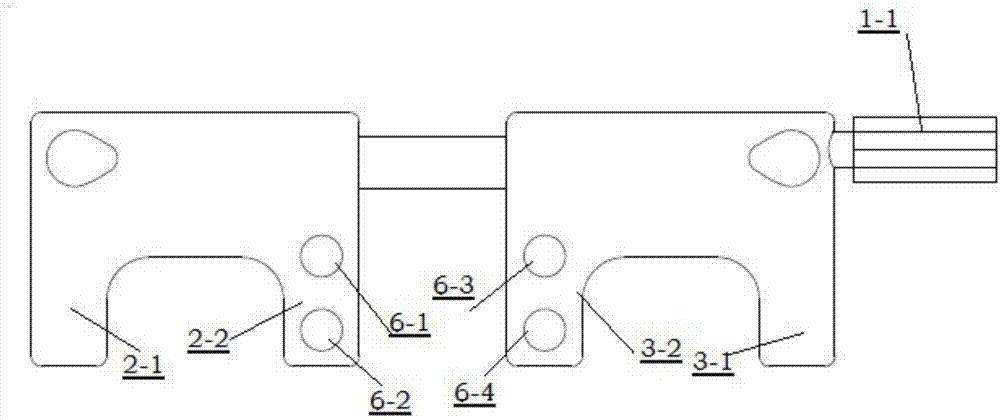

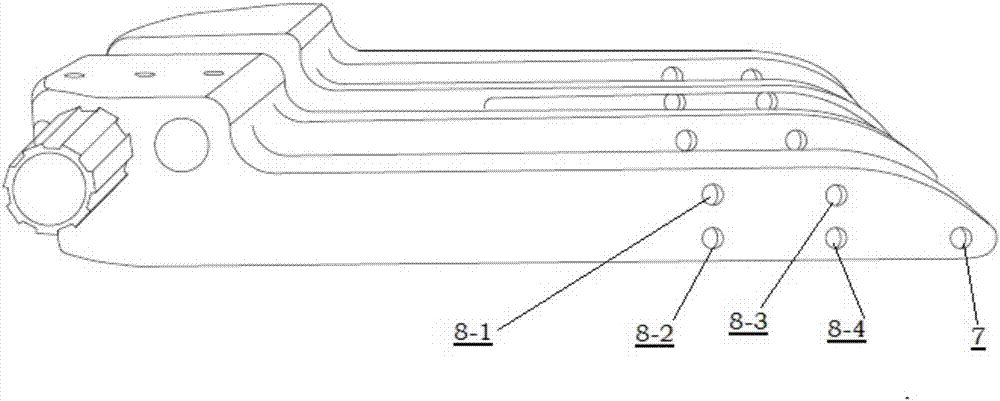

[0029] The Achilles tendon suturing assembly of the present invention includes a first fixing frame 2 and a second fixing frame 3 connected by a width adjuster 1 ; Wherein the first fixed mount 2 comprises the outer arm 2-1 of the first fixed mount, the inner arm 2-2 of the first fixed mount, constitutes the U-shaped arm of the first fixed mount 2; The outer arm 3-1 of the fixed mount and the inner arm 3-2 of the second fixed mount constitute the U-shaped arm of the second fixed mount 3;

[0030] The inside of the inner arm 2-2 of the first fixed mount and the inner arm 3-2 of the second fixed mount are respectively provided with two or more pull wire rod through holes 6 for inserting the pull wire rod 4;

[0031] There are suture thread holes 7 on the U-shaped arms of the first fixed frame 2 and the second fixed frame 3, and there are also needle holes 8 on the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com