Magnetic suction impurity removal device

A magnetic suction and magnetic sheet technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of reducing the service life of waste gas treatment equipment, and achieve the effect of easy cleaning and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

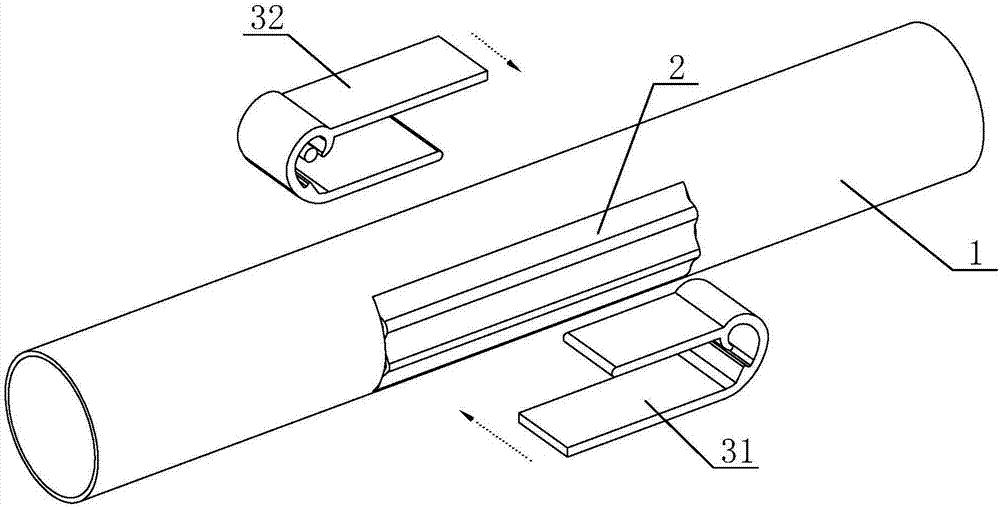

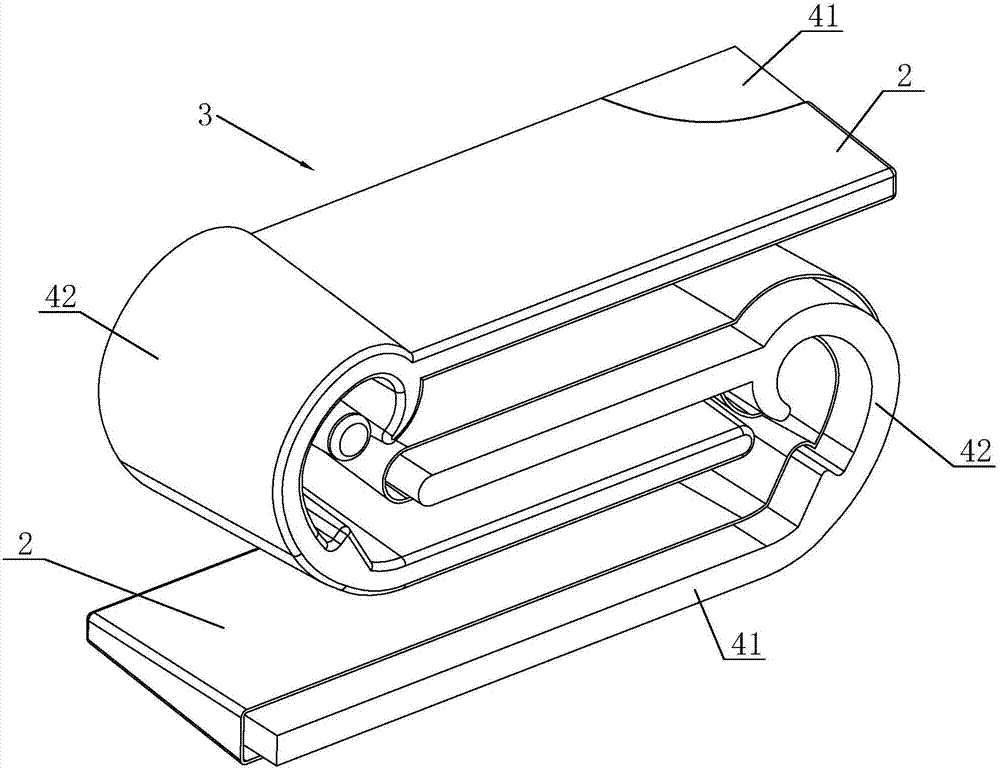

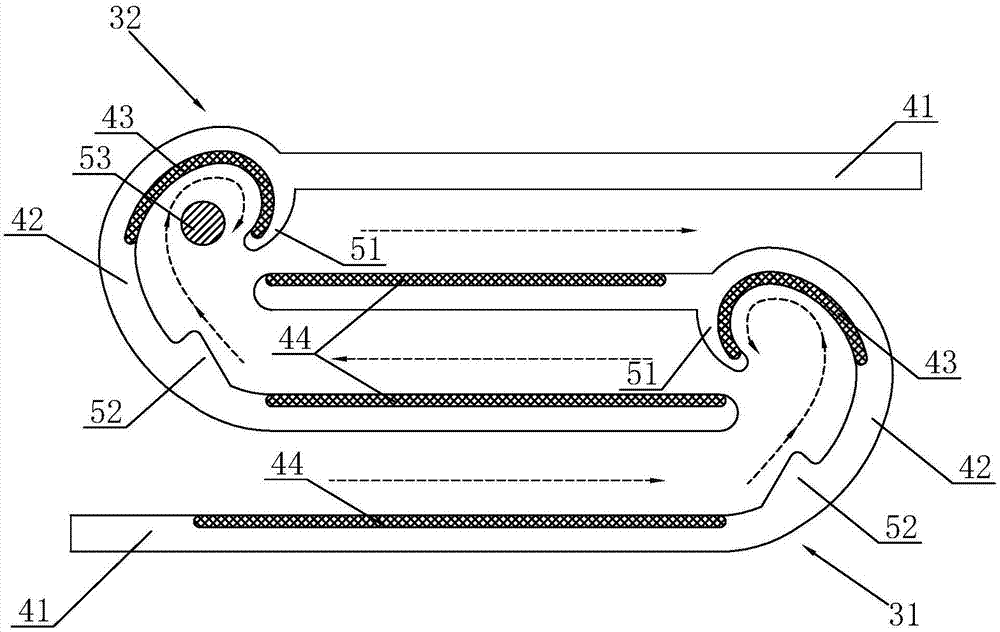

[0023] Such as figure 1 In the magnetic suction impurity removal device shown, the tube body 1 is provided with an air inlet for gas entering and a gas outlet for gas flowing out of the tube body 1, and the tube body 1 is provided with openings symmetrically left and right, and the opening is covered with a pressure film 2 , the pressure film 2 completely covers the two openings to ensure the airtightness of the inside of the tube body 1 except for the inlet and the gas outlet, and the pressure film 2 and the tube body 1 form a completely sealed gas channel. The magnetic suction impurity removal device is also provided with a voltage plate 3, and the voltage plate 3 is provided with a magnetic sheet for absorbing particles in the gas. The voltage plate 3 is divided into two plates, a lower pressing plate 31 and an upper pressing plate 32 . The lower pressing plate 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com