Welding clamp and method for radial stabilizer partition plate

A welding fixture and stabilizer technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of not meeting the requirements of assembly and use, welding deformation and deformation of radial stabilizers, to control welding deformation and ensure the pass rate. , to ensure the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with embodiment.

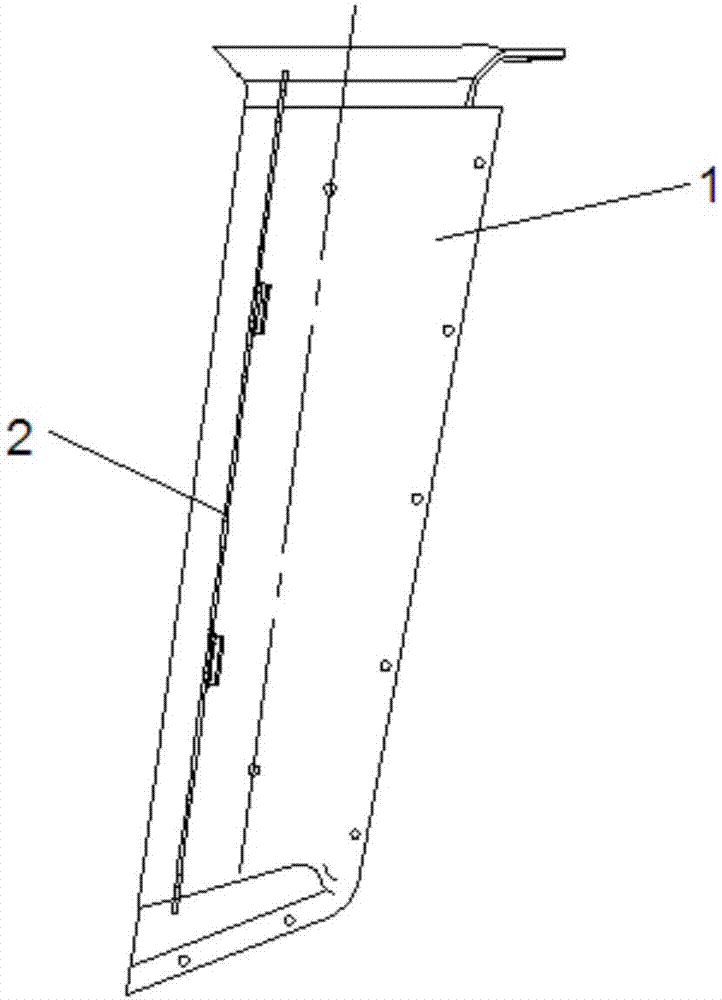

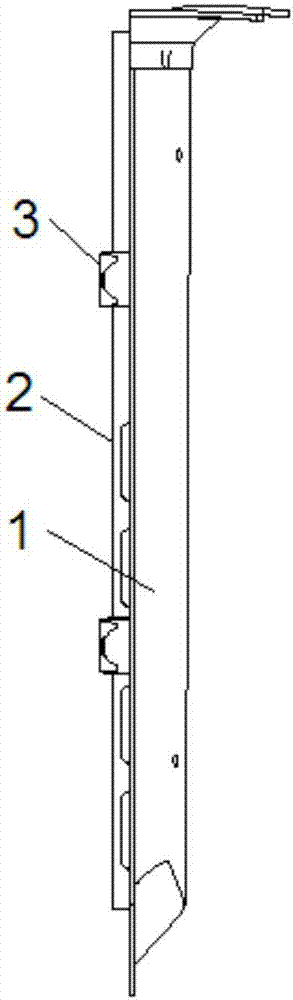

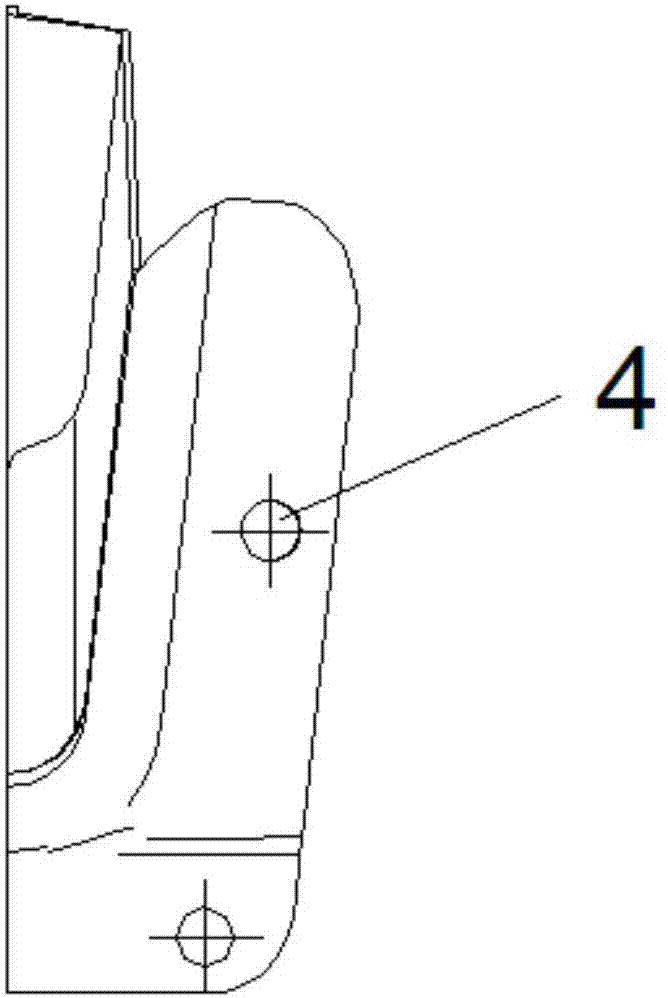

[0030] according to Figure 1 to Figure 5 As shown, a radial stabilizer diaphragm welding fixture provided by the present invention is used for clamping a radial stabilizer, and the radial stabilizer is composed of a radial stabilizer side plate 1, a radial stabilizer tail plate 2, Two nut brackets 3 are combined and welded, including: a base 5, on which a profile seat 6 and a first support 7 are fixed longitudinally, and lateral sides of the profile seat 6 are fixed with side The positioning block 8 and the second support 9, the inside of the profile seat 6 is provided with a groove 10 along the transverse direction, a protective block 11 is installed above the groove 10, and a plurality of ventilation holes 12 are arranged on the protective block 11 , the side positioning block 8 is inclined towards the end surface of the profile seat 6, and is matched with the inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com