Wire preassembling equipment

A wire and equipment technology, applied in the field of wire pre-installation equipment, can solve problems such as error-prone and low wire efficiency, and achieve the effect of easy placement, easy knotting, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

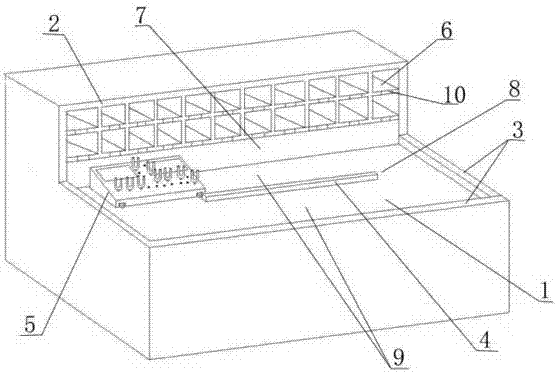

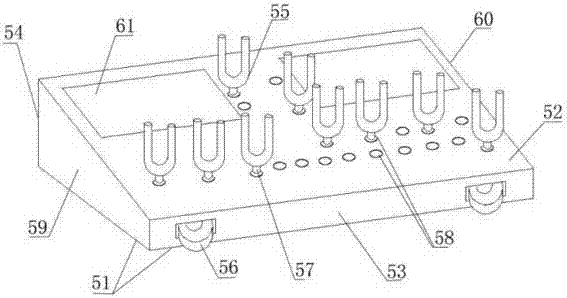

[0024] Such as figure 1 and figure 2 As shown, the wire pre-installation equipment includes a table top 1, a wire rack 2, a protective strip 3, a wire transfer vehicle 4, and an isolation strip 4;

[0025] The rear portion of the table 1 is provided with a pay-off rack 2 parallel to the track, and the surrounding edge of the table 1 is provided with a protective strip 3 higher than the table 1; the middle and upper parts of the pay-off rack 2 are provided with multiple Evenly arranged small squares 6, the lower part of the pay-off frame 2 is provided with a guide plate 7; the guide plate 7 and the protective strip 3 are provided with a spacer 4, the guide plate 7, the spacer 4 and the protective strip 3 Two parallel rows of rails 9 with the same width are formed together; the height of the protective strip 3 is greater than or equal to the height of the spacer strip 4;

[0026] The opening of the small square 6 faces the front of the table top 1;

[0027] A label 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com