Fruit conveying system and fruit picking robot

A conveying system and fruit technology, applied in the direction of picking machines, conveyors, conveyor objects, etc., can solve the problems of inconvenient picking and low picking efficiency, and achieve the effects of reducing labor intensity, improving transmission efficiency, and improving labor comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] figure 1 A schematic structural diagram of a fruit conveying system according to an embodiment of the present invention is shown.

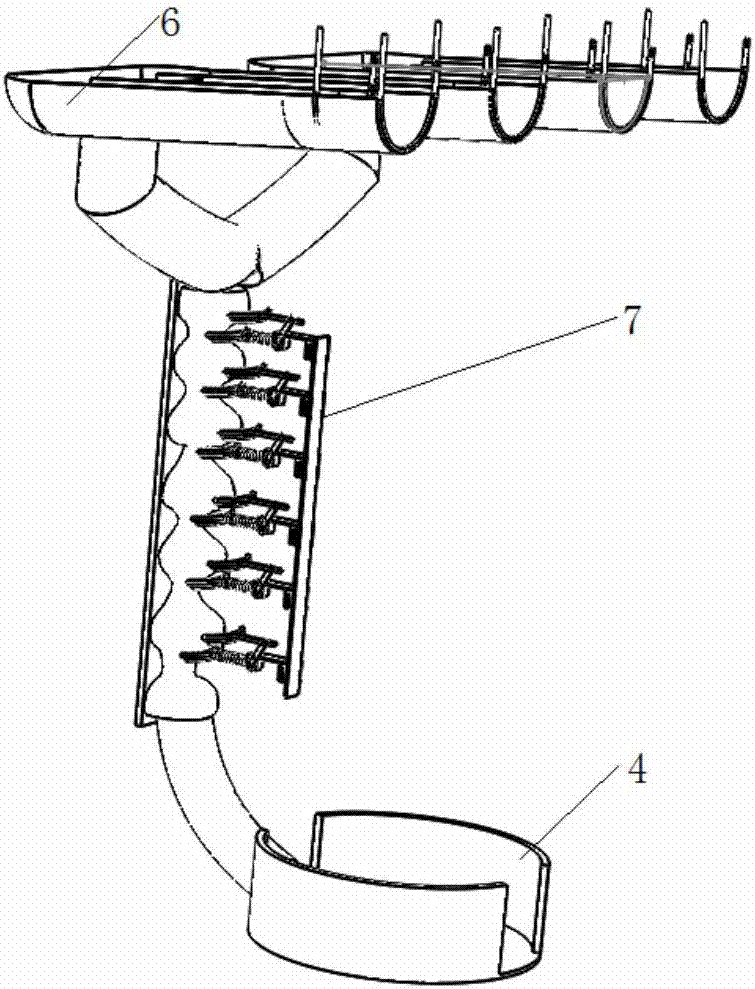

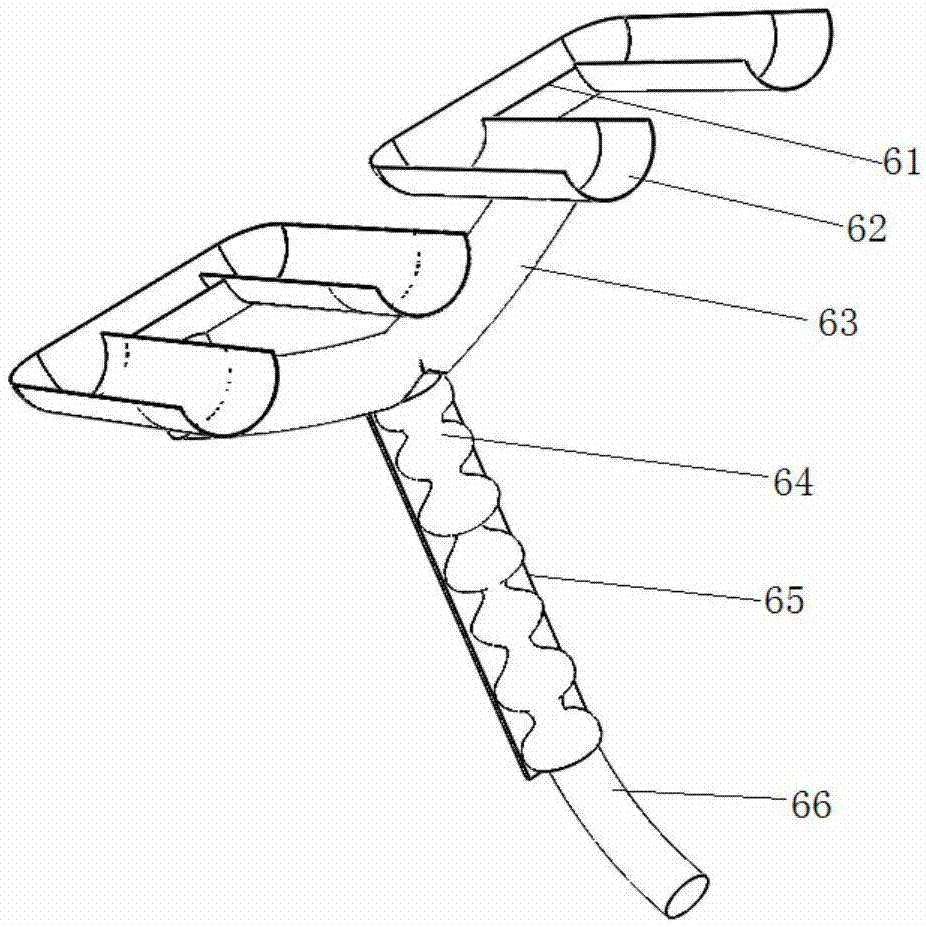

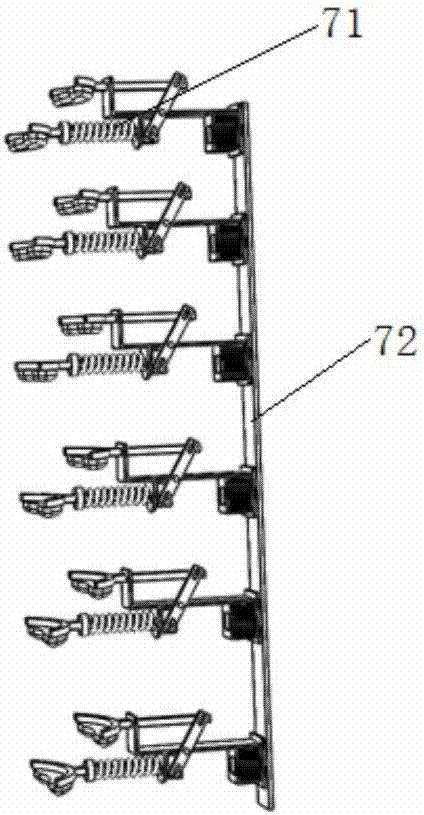

[0089] Such as figure 1 As shown, the present embodiment proposes a kind of fruit delivery system, and this delivery system comprises: fruit transmission mechanism 6, and fruit transmission mechanism 6 comprises the transmission pipeline that connects successively, connection pipeline 63, wide-mouth pipeline 64 and outlet pipeline 66, transmission The pipeline is arranged on the pipeline rack, so that the fruit transmission mechanism 6 is connected with the picking device; the pipeline peristaltic mechanism 7, the pipeline peristaltic mechanism 7 includes a solenoid valve mounting plate 72 and a plurality of peristaltic solenoid valves 71 arranged on the solenoid valve mounting plate 72, and the A peristaltic electromagnetic valve 71 is correspondingly arranged with the wide mouth pipeline 64 of the fruit transmission mechanism 6, and is u...

Embodiment 2

[0131] Such as Figure 1-Figure 19 As shown, the fruit picking robot includes: robot chassis 5; lifting device, the lifting device is arranged on the top of the robot chassis 5; picking device 1, and the picking device 1 is arranged on the top of the lifting device; fruit transmission mechanism 6, one end of the fruit transmission mechanism 6 Connected to the bottom of the picking device 1, the other end is connected to the fruit branch separation device; the fruit branch separation device 4 is arranged on the top of the robot chassis 5; wherein the picking device includes a picking rack 11, a picking rack 18, and a picking sleeve 182 1. Picking sleeve transmission mechanism, cutter 185, picking frame 11 is arranged on the lifting device top, picking tooth bar 18 is vertically arranged on picking frame 11, picking sleeve 182 is sleeved on picking tooth bar 18, picking one end of the sleeve transmission mechanism It is fixed on the picker frame 11 and the other end is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com