Tunnel secondary-lining steel bar binding and positioning device

A secondary lining and steel bar binding technology, which is applied in the field of reinforced concrete, can solve the problems of long positioning process time, difficult points, and low precision, and achieve the effects of simple construction, reduced exposed bars, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

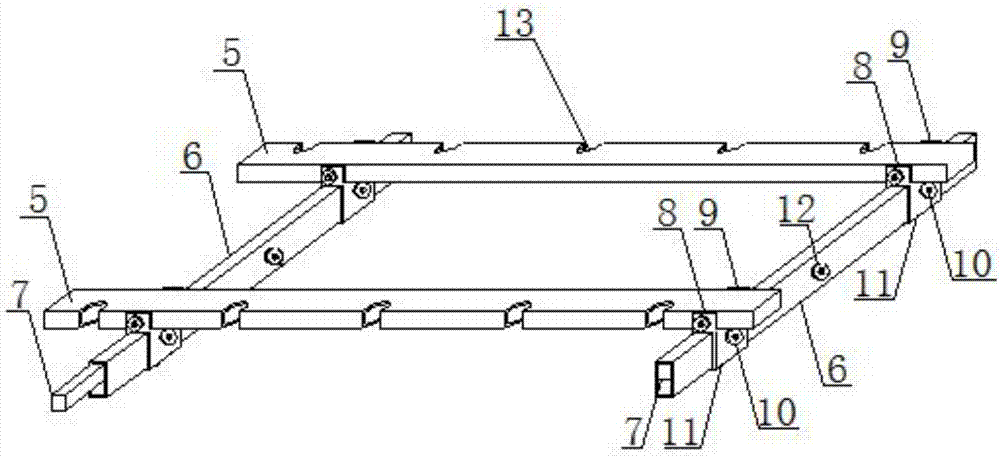

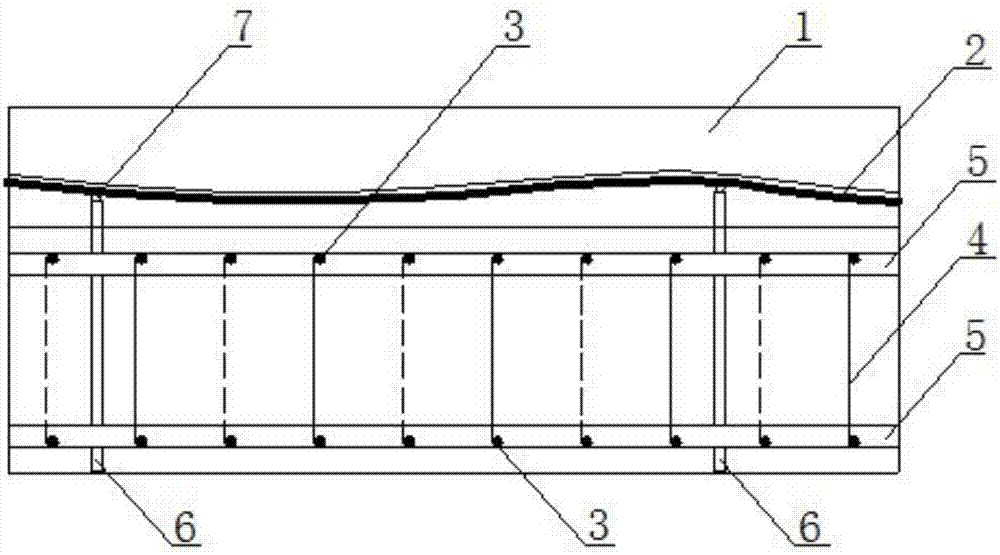

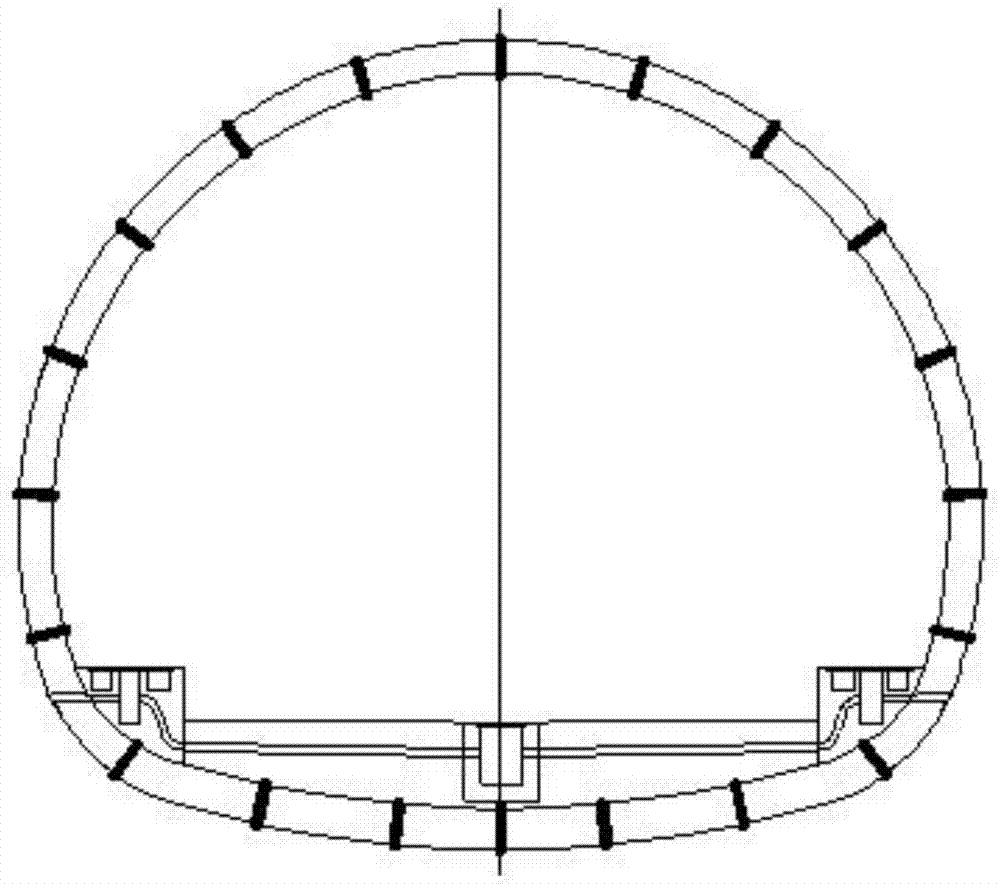

[0021] see Figure 1 to Figure 2 , a tunnel secondary lining steel bar binding positioning device, including longitudinal steel clamp 5 braces 6 . The length of the longitudinal reinforcement fixture 5 is determined according to the longitudinal distance between the adjacent positioning points of the secondary lining reinforcement. The spacing is the design spacing of the secondary lining reinforcement. The length of the strut 6 is about two lining thicknesses, and the strut 6 is made of a rectangular rod with a suitable section. A retractable push rod 7 is arranged inside the support rod 6. The length of the retractable push rod 7 is the maximum length from the section of the primary support 1 to the outer limit of the secondary lining design, and is used to control the waterproof layer 2 to the circumferential reinforcement 3 on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com