Wiring harness waterproof connecting structure

A wire harness and transfer technology, applied in the direction of connection, parts of the connection device, electrical components, etc., can solve the problem of short service life of the connection parts, and achieve the effect of solving damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

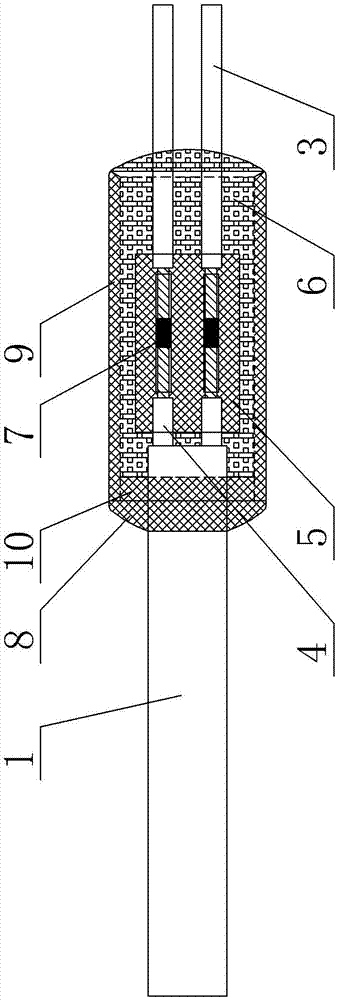

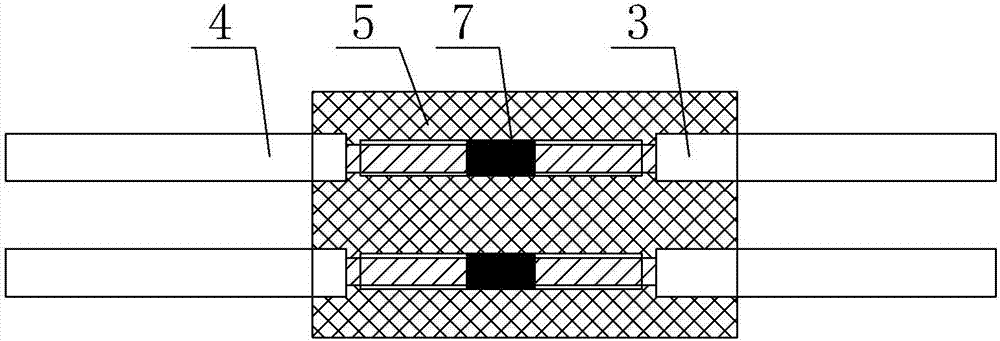

[0020] A wiring harness waterproof transfer structure, see Figure 1-Figure 5 : It includes the wire harness 1 and the core wire 3 corresponding to the external connection part 2, the length direction of the corresponding wire 4 of the wire harness 1 is exposed on the overall length end face of the wire harness 1, and the exposed end of the corresponding wire 4 is connected to the core wire 3 through the PCB board 5 At the end, the whole part of the PCB board 5 is encapsulated with waterproof glue 6 , and the waterproof glue 6 extends to the overall outer ring surface of the wire harness 1 and the outer ring surface of each core wire 3 .

[0021] The PCB board 5 is provided with a double-sided pad 7, and the exposed end corresponding to the wiring 4 and the corresponding core wire 3 correspond to the double-sided pad 7 of the PCB board 5 for one-to-one welding connection to ensure the uniform distribution of the core wire 3, so that the core wire 3 The force of the line is eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com