Composite linkage type double-cylinder system

A linkage type and drive cylinder technology, which is applied in the field of hydraulic cylinders, can solve the problems of low rigidity of synchronous telescopic cylinders and the inability to achieve large load movement requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

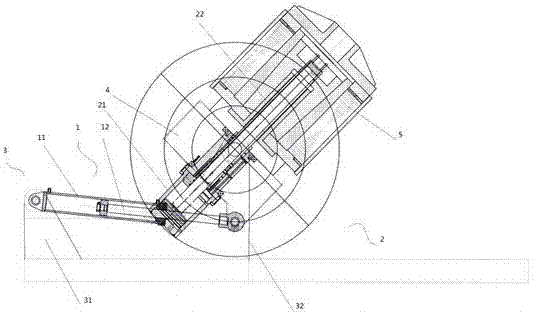

[0013] Such as figure 1 A compound linkage double-cylinder system shown includes a first driving cylinder 1 , a second driving cylinder 2 , a fixed seat 3 and a movable seat 4 .

[0014] The fixed seat 3 has a pair that includes the first fixed seat 31 and the second fixed seat 32 and is arranged along the horizontal direction, and the height of the first fixed seat 31 is lower than the height of the second fixed seat 32; A hinge hole is provided; the first drive cylinder 1 includes a first cylinder liner 11 and a first piston rod 12, one end of the first cylinder liner 11 is hinged on the first fixed seat 31, and the first piston rod 12 is along the The inner wall of the first cylinder liner 11 slides, and the end of the first piston rod 12 is hinged on the movable seat 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com