Installation device and installation method

A technology of installation device and installation position, applied in the direction of electrical components, electrical components, etc., can solve the problems of high production line cost, large-scale device, production takt delay, etc., and achieve the effect of improving production takt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

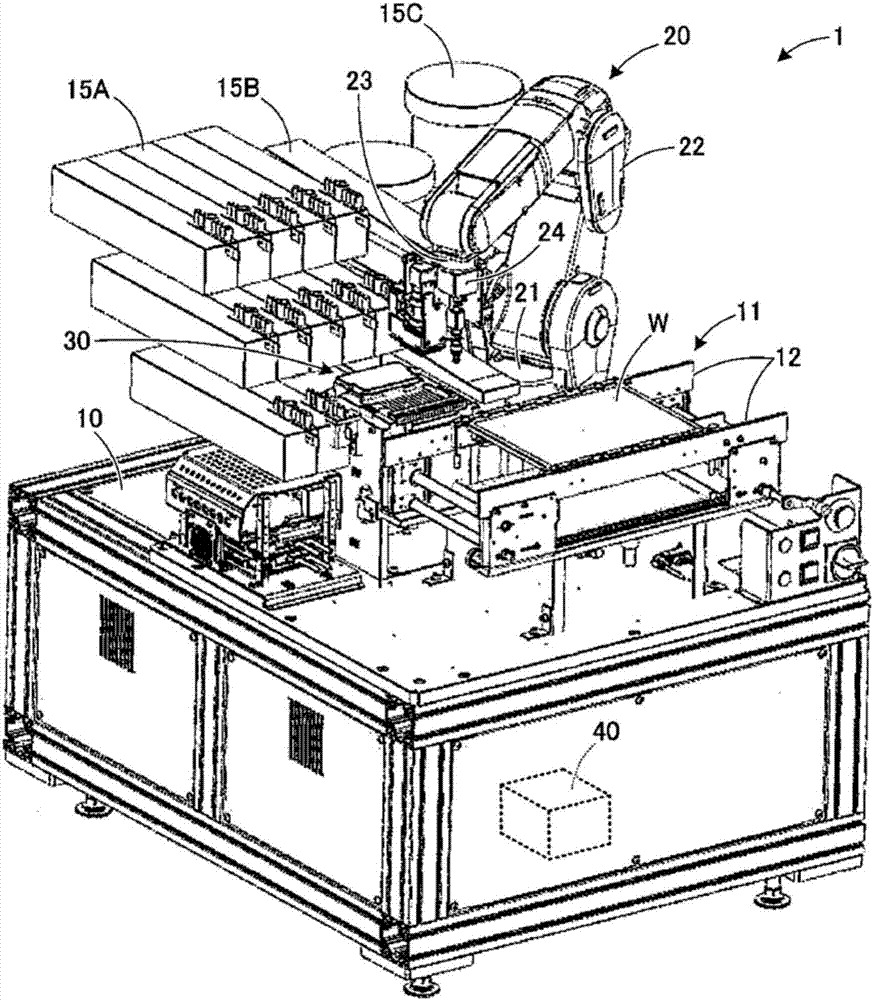

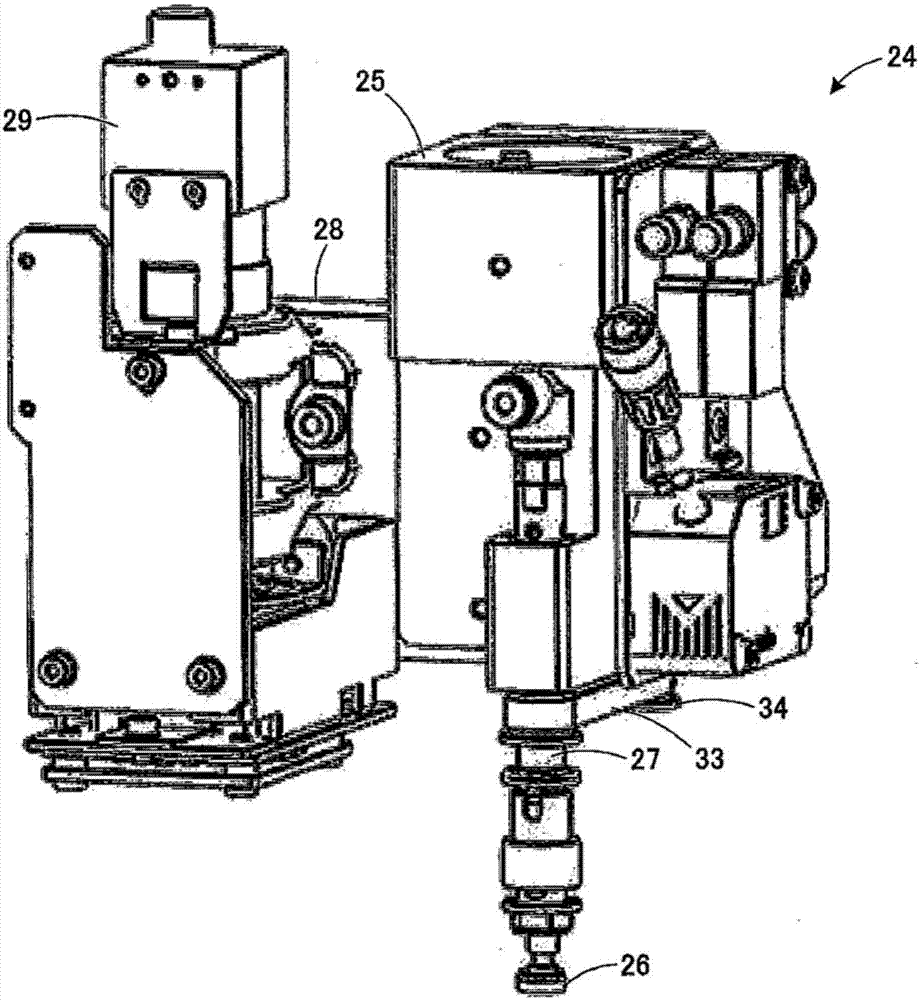

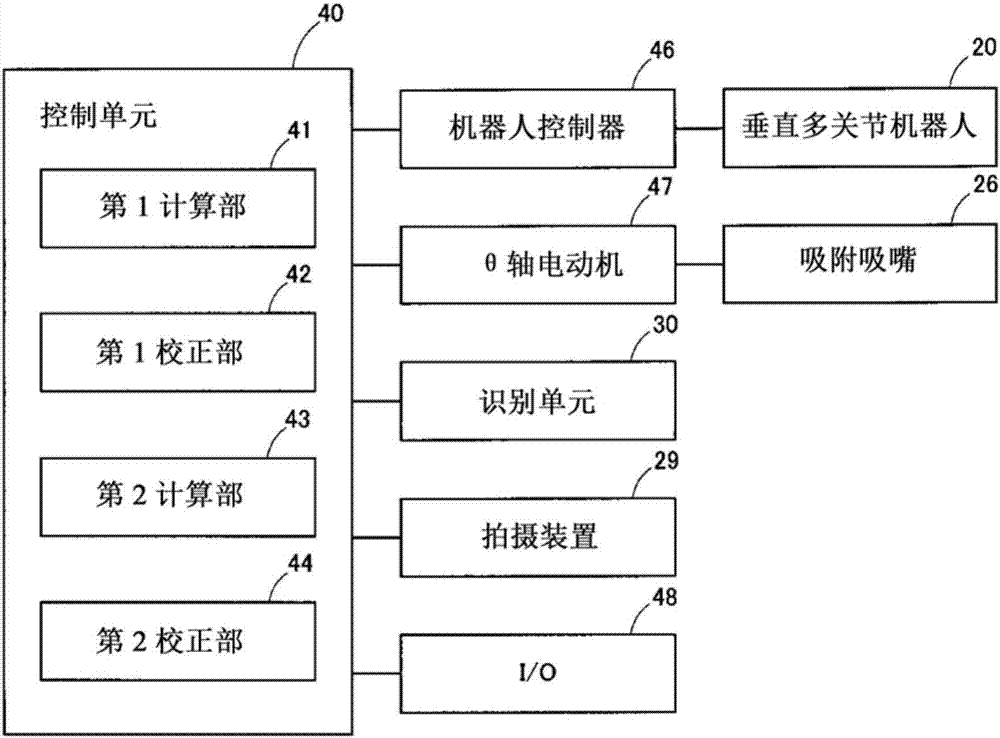

[0043] Next, the mounting device of this embodiment will be described with reference to the drawings. figure 1 It is a perspective view of the whole mounting device of this embodiment. figure 2 It is a perspective view of the mounting head of the mounting device of this embodiment. In addition, the attachment device of this embodiment is just an example, and can be changed suitably.

[0044] Such as figure 1 As shown, the mounting device 1 is configured to mount components supplied from various feeders (supply devices) 15A to 15C on the mounting surface of the substrate W by the vertical articulated robot 20 . On the base 10 of the mounting device 1 is arranged a transport unit 11 that transports the substrate W toward the work area in front of the vertical articulated robot 20 . The conveying unit 11 constitutes a conveying path by a pair of guide rails 12 that guide the conveyance of the substrate W and a pair of conveyer belts (not shown). The pair of conveyer belts sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com