Rubber sealing strip on-line punching machine capable of adjusting punching space

A technology of rubber sealing strip and hole spacing, which is applied in metal processing and other directions, can solve the problems of large deviation and difficult product quality to fully meet the requirements, and achieve the effect of preventing deviation and ensuring the quality of punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

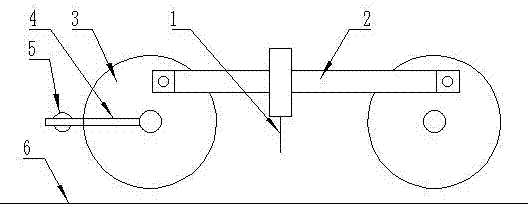

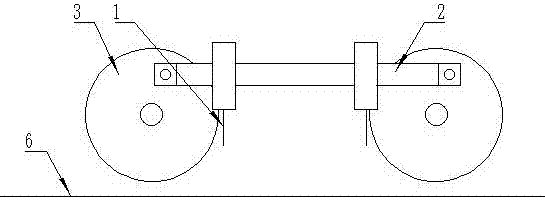

[0013] Such as figure 1 An online punching machine for rubber sealing strips with adjustable punching spacing is shown, including a pallet 6 with a product, and a punching head 1 facing the pallet 6. Circular movement, the drive mechanism includes two motor-driven, synchronously rotating drive wheels 3, and a horizontal support bar 2 that is connected to the two drive wheels 3 at both ends, and the punching head 1 is installed on the support bar 2, one side of one of the driving wheels 3 is provided with a detection mechanism 5 as a demarcation point, and the driving wheel 3 is provided with a trigger mechanism 4, which divides each circumference of the punching head 1 into motions close to the support through the demarcation point. The punching section of the platform 6 and the disengagement section away from the pallet 6, the linear velocity of the driving mechanism driving the punching head 1 in the punching section is equal to the advancing speed of the strip material on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com