Non-gasket prefabricating device for high-speed railway deck covering plate

A technology for railway bridges and shrouds, applied in the manufacture of tools, ceramic molding machines, molds, etc., can solve the problems of affecting the shape and increasing construction costs, and achieve the effects of guaranteed quality, low cost, and good airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

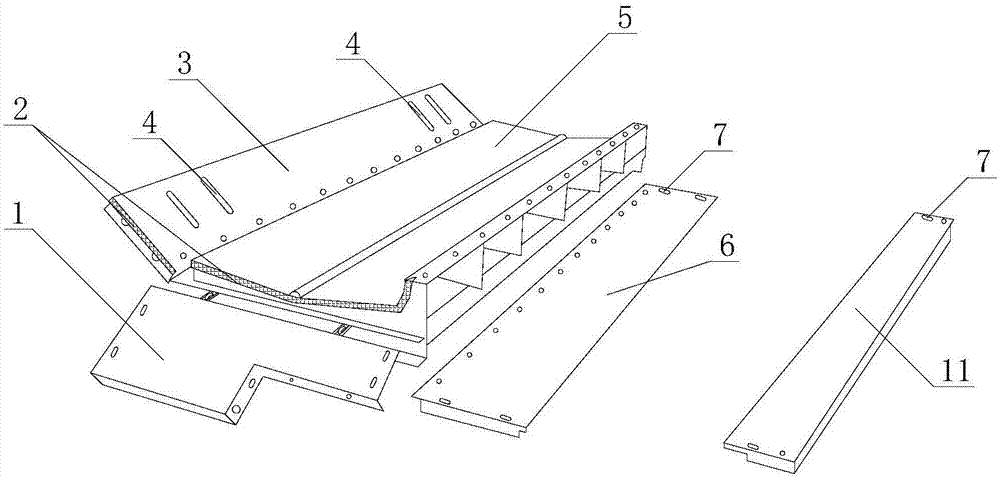

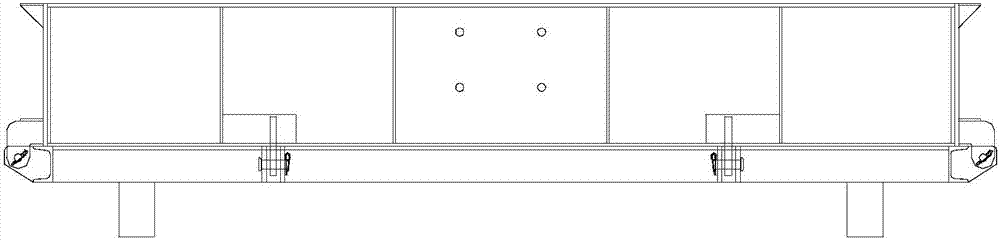

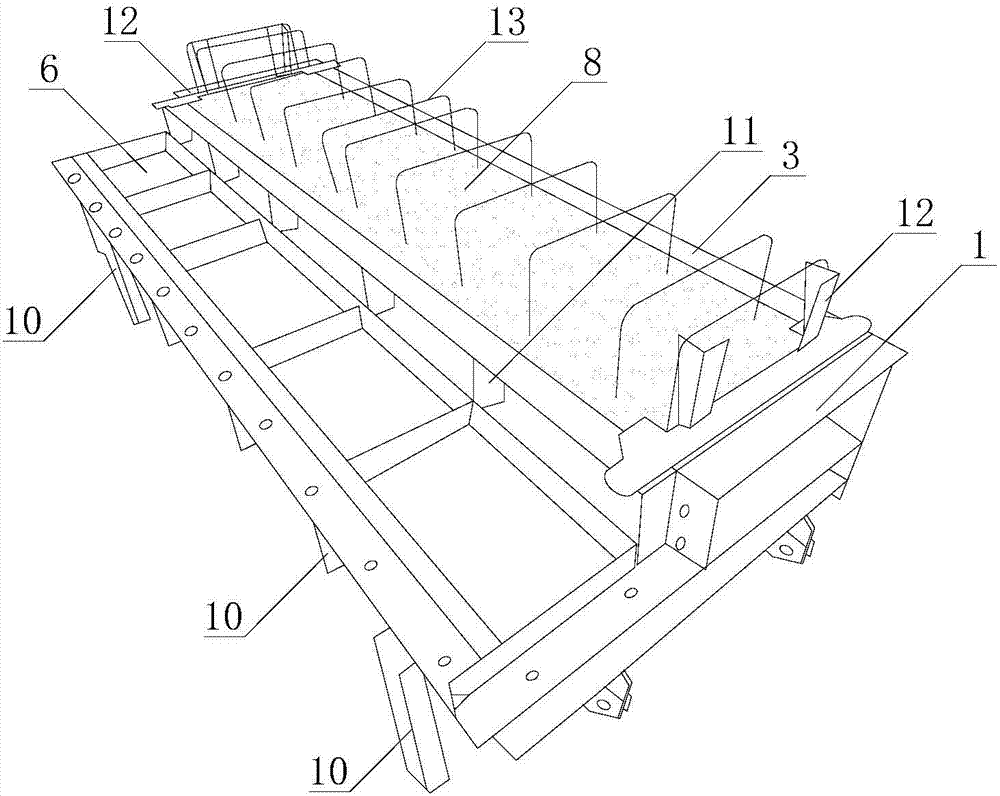

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0037] Traditional high-speed railway bridge deck shutters8 such as Figure 7 and Figure 8 As shown, in the process of making, the reinforcement cage 13 (such as Figure 5 and Figure 6 Shown) placed in the mold, and then filled with concrete to achieve. The reinforcement cage 13 needs to have a part of the steel bars exposed outside, so the reinforcement cage 13 includes an embedded part and an exposed part, and the exposed part is a U-shaped steel bar. More specifically, the reinforcement cage 13 includes a vertical steel bar 13.1, a horizontal fixed steel bar 13.2, a 6-shaped steel bar 13.3 and a longitudinal steel bar 13.4, and the horizontal fixed steel bar 13.2 fixes the vertical steel bar 13.1, the 6-shaped steel bar 13.3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com