Automatic belt butt joint device

An automatic and adhesive tape technology, which is applied in transportation and packaging, electrode manufacturing, winding strips, etc., can solve the problems of high labor cost, long time consumption of docking, low efficiency, etc., and achieve the effect of reducing human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

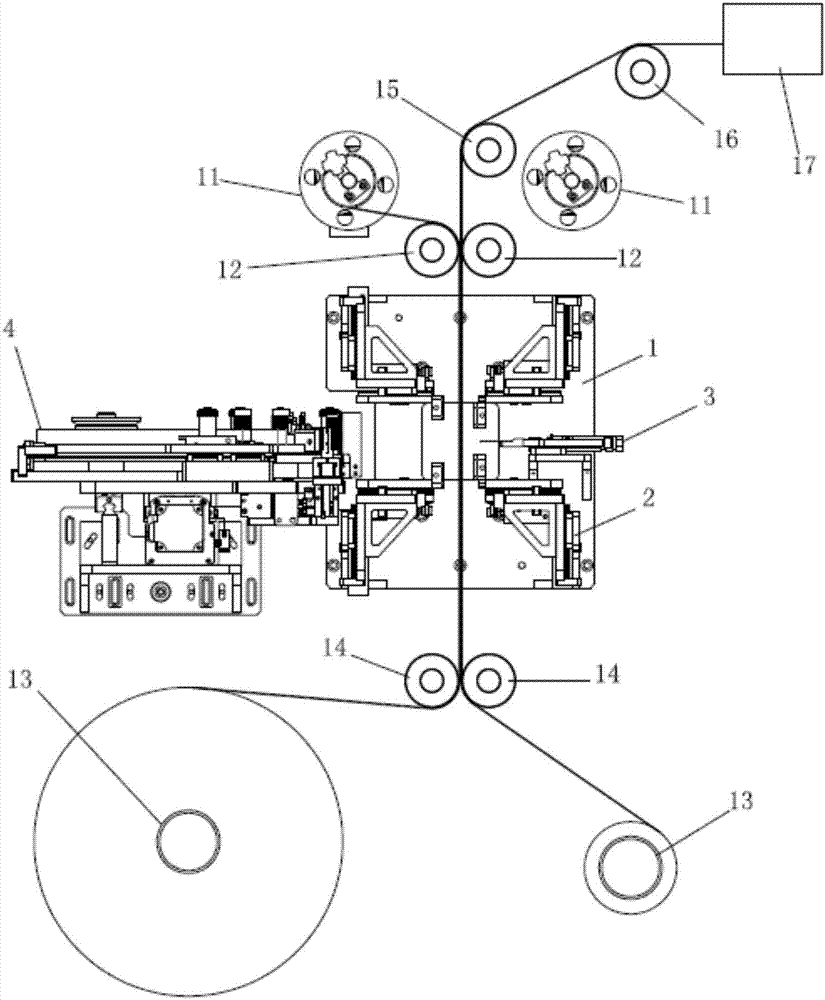

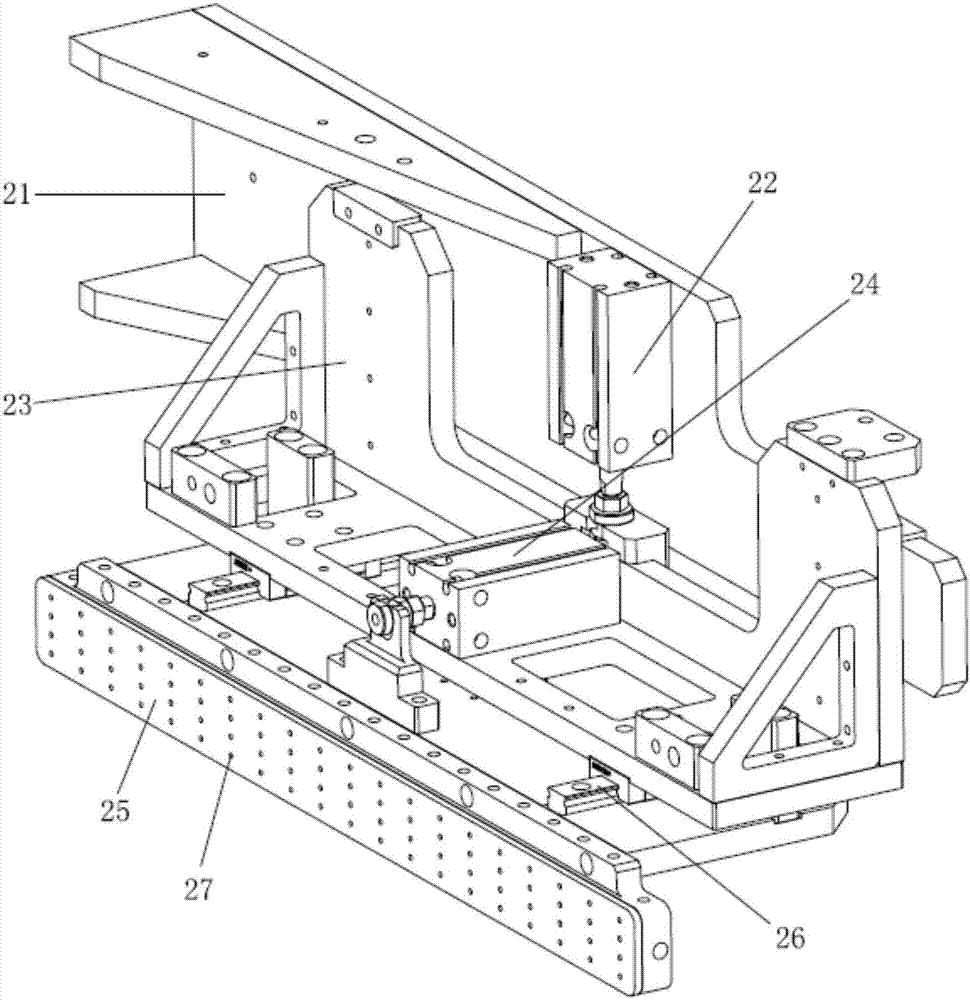

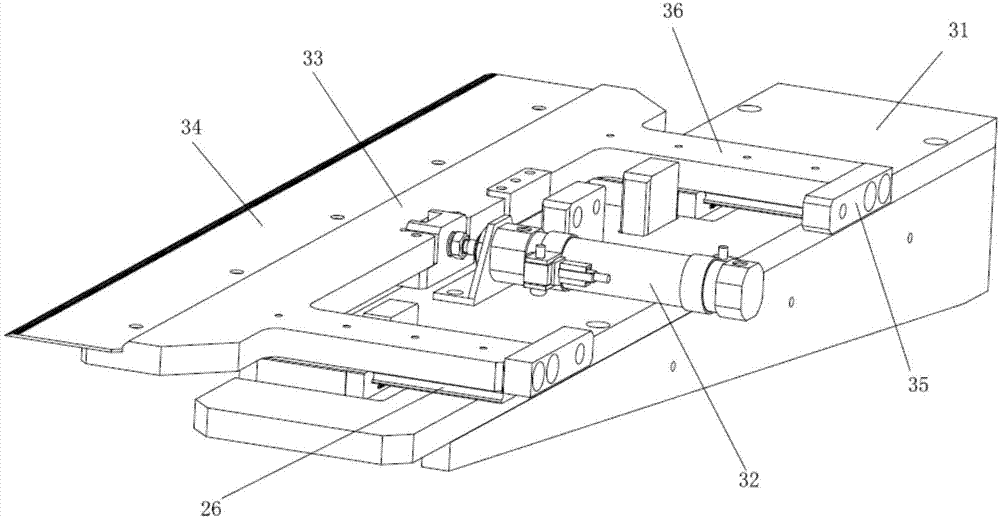

[0028] Such as Figure 1 to Figure 4 As shown, the automatic tape splicing device shown in this embodiment includes four suction plate mechanisms arranged up and down in two rows symmetrically arranged, two sets of winding material rotating shaft mechanisms arranged on the left and right sides above the suction plate mechanism, and located on the left and right sides of the suction plate mechanism. There are two sets of unwinding rotating shaft mechanisms on the left and right sides below the suction plate mechanism, and a tape sticking mechanism and a cutter mechanism respectively located on the left and right sides of the suction plate mechanism; the four suction plate mechanisms and the cutter mechanism are all fixed on the resin wall. On the board; the winding material rotating shaft mechanism includes the winding material rotating shaft and the first guide wheel, the unwinding material rotating shaft mechanism includes the unwinding material rotating shaft and the second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com