Diesel engine cylinder crack detection equipment

A detection equipment, diesel engine technology, applied in liquid tightness measurement using liquid/vacuum degree, measuring device, mechanical device, etc. It can solve the problems of polluting the environment, failing to find the location of leaking cracks in time and not saving resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

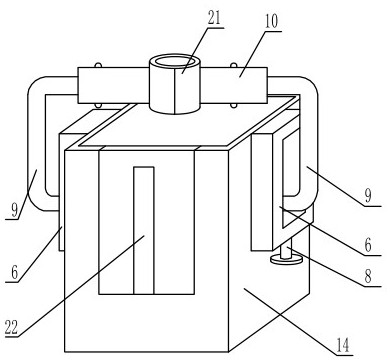

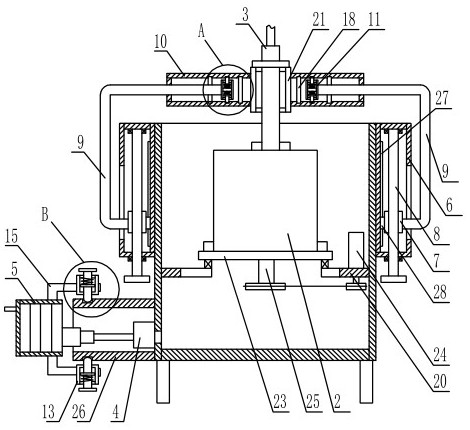

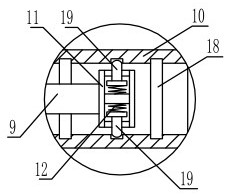

[0020] Such as figure 1 and figure 2 As shown, the present invention provides an embodiment of a diesel engine cylinder block crack detection device, which includes a water storage tank 1 and a diesel engine cylinder block 2, and the water storage tank 1 can be placed on the automatic detection line. Of course, the diesel engine can also be implemented separately The detection of the cylinder block 2, the specific structure of the diesel engine block is the prior art, and it is simply shown in the figure, the top of the water storage tank 1 is open, and the water storage tank 1 is provided with The bracket 20, in the present embodiment, the bracket 20 is rotatably connected with a tray 23, the diesel engine cylinder 2 can be placed on the tray 23, the water storage tank 1 is equipped with a drive motor 24 that drives the tray 23 to rotate, and the tray 23 is mounted Driven shaft 25 is arranged, and the power output shaft of driven shaft and drive motor 24 is dynamically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com