Method for improving shock resistance of Y-shaped pier

A bridge pier and capacity technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of complex design of Y-shaped piers and weak seismic performance, and achieve the effects of improving mechanical performance, convenient positioning and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

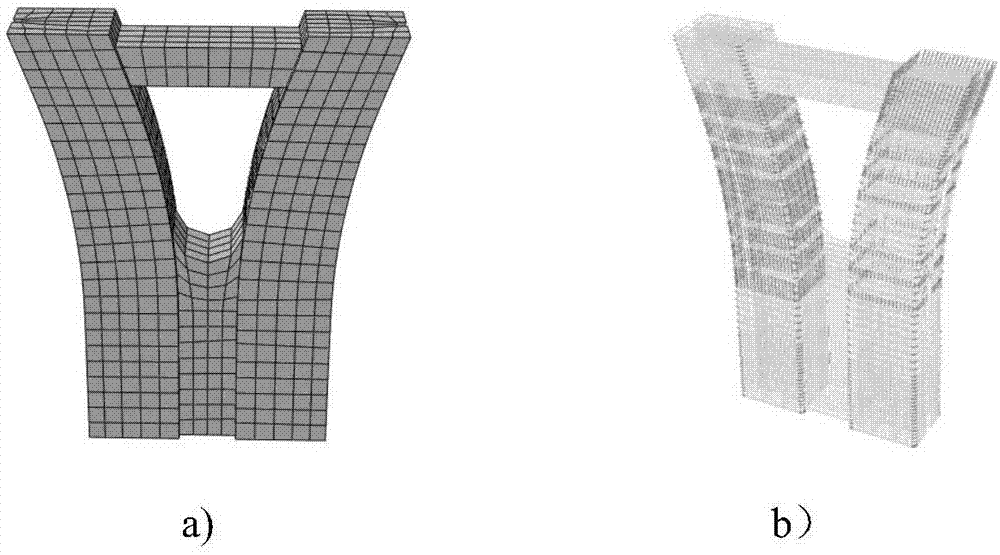

[0029] The urban elevated Y-shaped pier in this embodiment has a bottom section size of 160cm × 500cm, and the cross-sectional size of the arms and legs is 160cm × 190cm. The pier body material of the urban elevated Y-shaped pier is C40 concrete, and the pier body of the urban elevated Y-shaped pier Use HRB335 steel bar.

[0030] (1) a method for improving the seismic capacity of Y-type bridge piers, comprising the following steps:

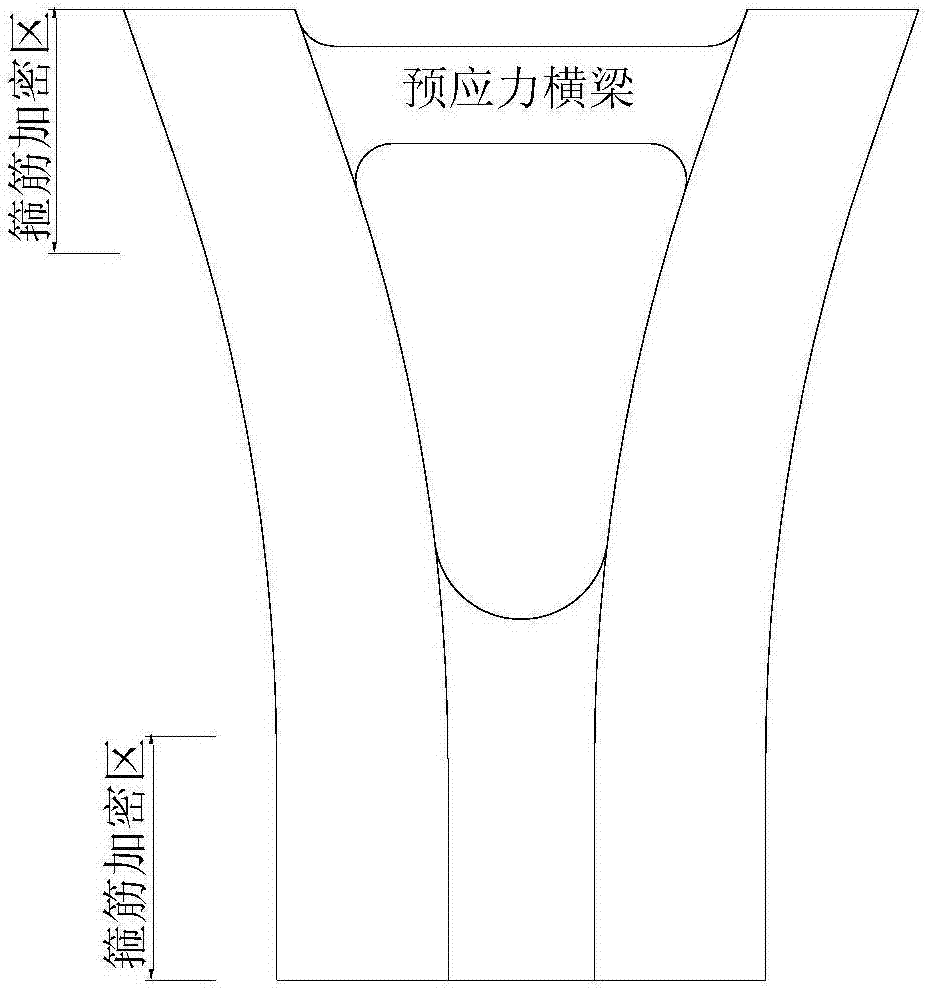

[0031] Step 1. Beam reinforcement

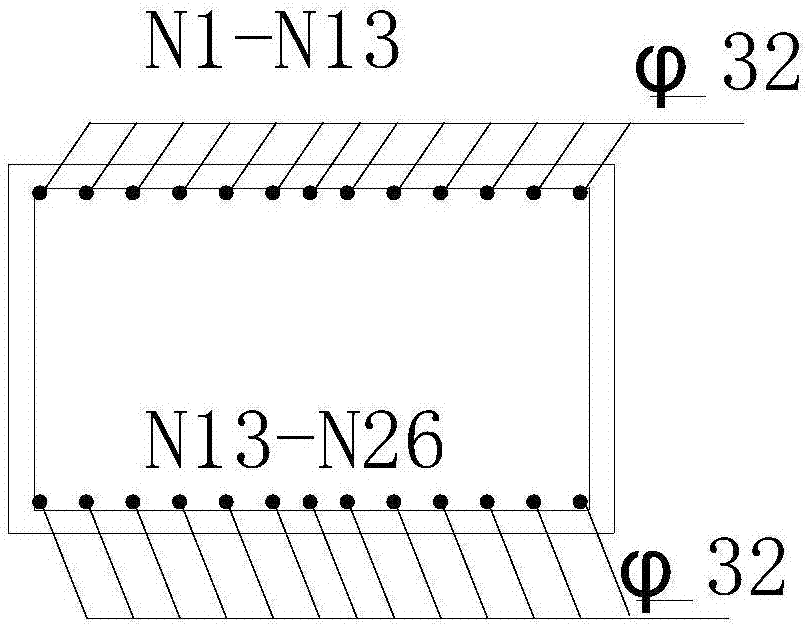

[0032] A crossbeam is set between the two limbs of the Y-shaped pier to connect the two limbs. At the same time, prestressed steel bars are arranged on the crossbeams of the Y-shaped pier. See figure 1 , specifically, arrange a row of N1-N13 prestressed steel bars at the upper end of the beam, and arrange a row of N14-N26 prestressed steel bars at the lower end of the beam;

[0033] The prestressed steel bars form the prestressed steel tendons, and the external force generated by the prestressed steel tendons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com