Electric excavator

A technology for electric excavators and traveling motors, which is applied to earth movers/shovels, construction, etc. It can solve problems such as low work efficiency, restriction of construction machinery, and large noise, and achieve the goal of saving hydraulic oil energy and hydraulic energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

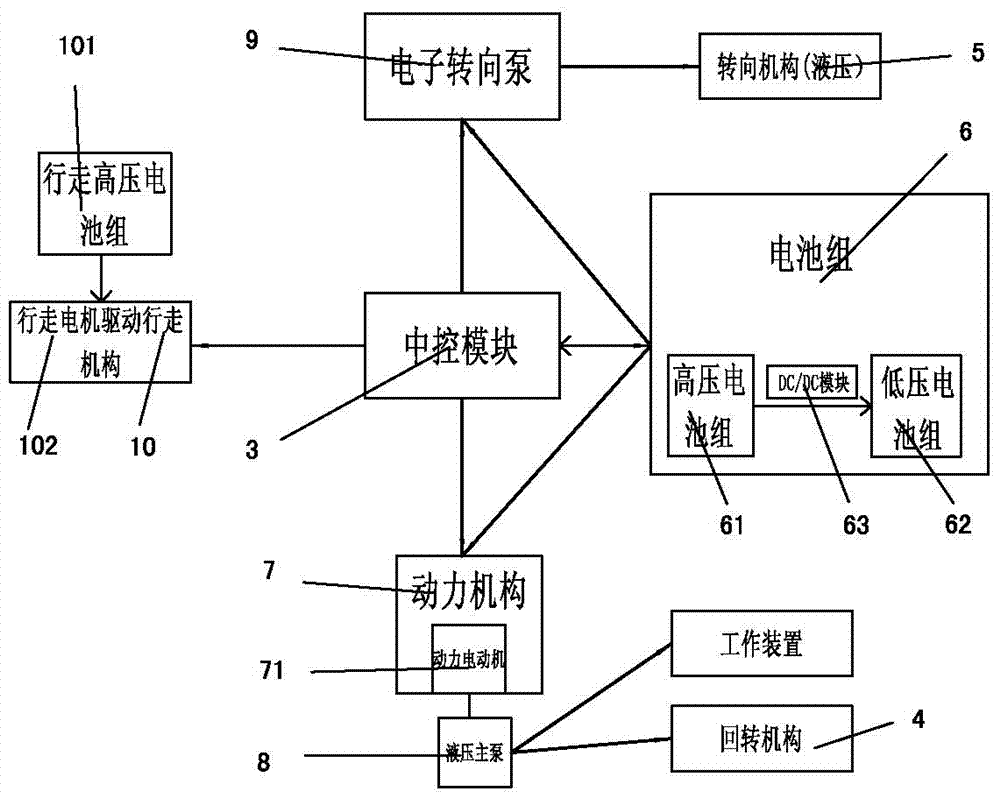

[0024] Such as figure 1 , Image 6 , Figure 7 As shown, an electric excavator of the present invention includes a cab, a slewing platform 1 and an undercarriage 2 , and the cab is located at the upper front side of the slewing platform 1 . The cab is provided with a central control module 3 .

[0025] The slewing platform 2 is provided with a slewing mechanism 4 , a steering mechanism 5 , a battery pack 6 , a power mechanism 7 , a hydraulic main pump 8 and an electronic steering pump 9 .

[0026] The slewing mechanism 4 is driven by a hydraulic main pump 8 to work.

[0027] Battery pack 6 comprises high-voltage battery pack 61 and low-voltage battery pack 62, and low-voltage battery pack 62 is positioned at the side of high-voltage battery pack 61; DC / DC module 63 is arranged between high-voltage battery pack 61 and low-voltage battery pack 62, makes low-voltage battery pack The power supply of 62 can be obtained by inverter of high-voltage battery pack 61; The battery p...

Embodiment 2

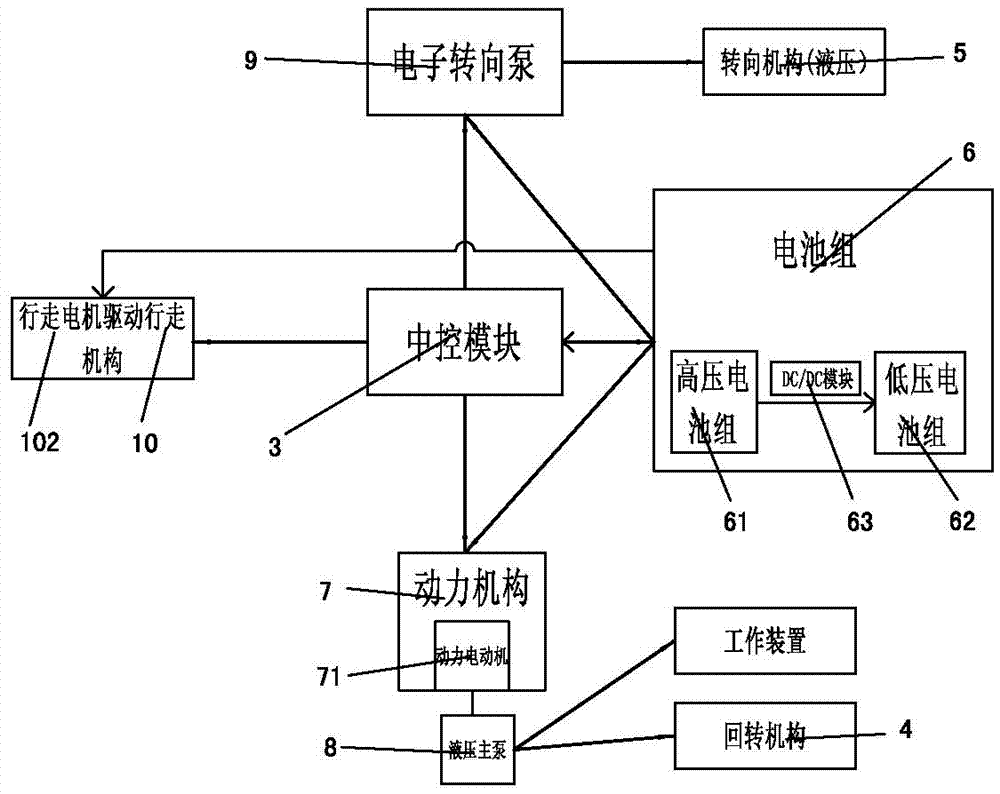

[0033] Such as figure 2 , Image 6 As shown, an electric excavator of the present invention includes a cab, a slewing platform 1 and an undercarriage 2 , and the cab is located at the upper front side of the slewing platform 1 . The cab is provided with a central control module 3 .

[0034] The slewing platform 2 is provided with a slewing mechanism 4 , a steering mechanism 5 , a battery pack 6 , a power mechanism 7 , a hydraulic main pump 8 and an electronic steering pump 9 .

[0035] The slewing mechanism 4 is driven by a hydraulic main pump 8 to work.

[0036] Battery pack 6 comprises high-voltage battery pack 61 and low-voltage battery pack 62, and low-voltage battery pack 62 is positioned at the side of high-voltage battery pack 61; DC / DC module 63 is arranged between high-voltage battery pack 61 and low-voltage battery pack 62, makes low-voltage battery pack The power supply of 62 can be obtained by inverter of high-voltage battery pack 61; The battery pack 6 is ele...

Embodiment 3

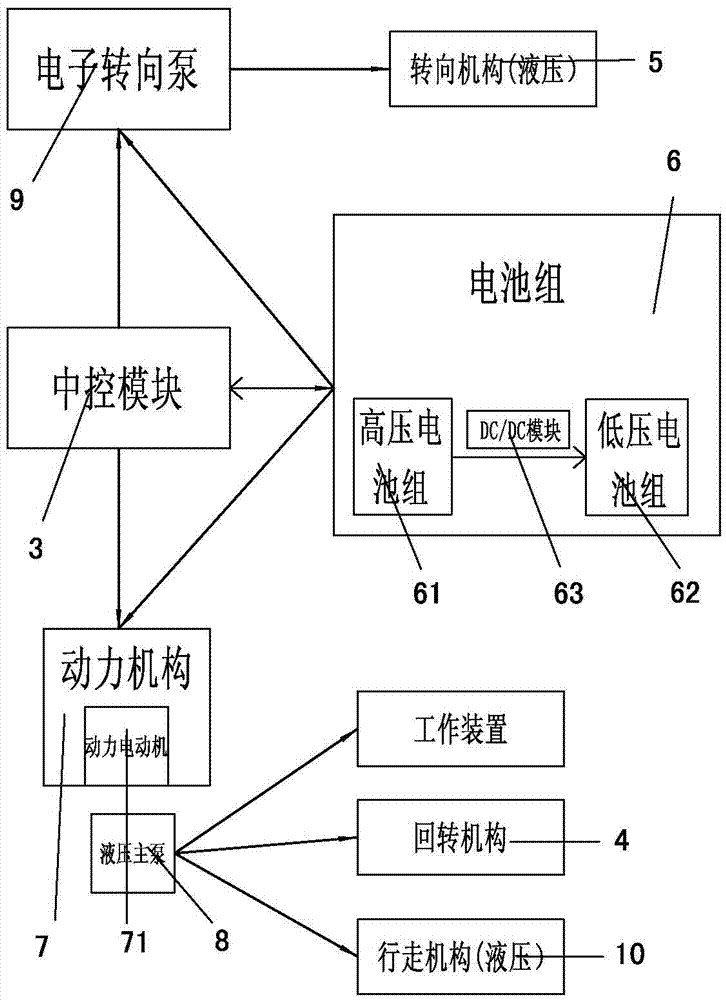

[0042] Such as image 3 , Image 6 , Figure 8 As shown, an electric excavator of the present invention includes a cab, a slewing platform 1 and an undercarriage 2 , and the cab is located at the upper front side of the slewing platform 1 . The cab is provided with a central control module 3 .

[0043] The slewing platform 2 is provided with a slewing mechanism 4 , a steering mechanism 5 , a battery pack 6 , a power mechanism 7 , a hydraulic main pump 8 and an electronic steering pump 9 .

[0044] The slewing mechanism 4 is driven by a hydraulic main pump 8 to work.

[0045] Battery pack 6 comprises high-voltage battery pack 61 and low-voltage battery pack 62, and low-voltage battery pack 62 is positioned at the side of high-voltage battery pack 61; DC / DC module 63 is arranged between high-voltage battery pack 61 and low-voltage battery pack 62, makes low-voltage battery pack The power supply of 62 can be obtained by inverter of high-voltage battery pack 61; The battery pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com