Composite supporting heat dissipation structure for portable electronic devices

A composite support, electronic device technology, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, etc., can solve the problems of high touch temperature for consumers, hot body, crash, etc., to overcome the maximum heat dissipation area , the effect of good human-machine experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

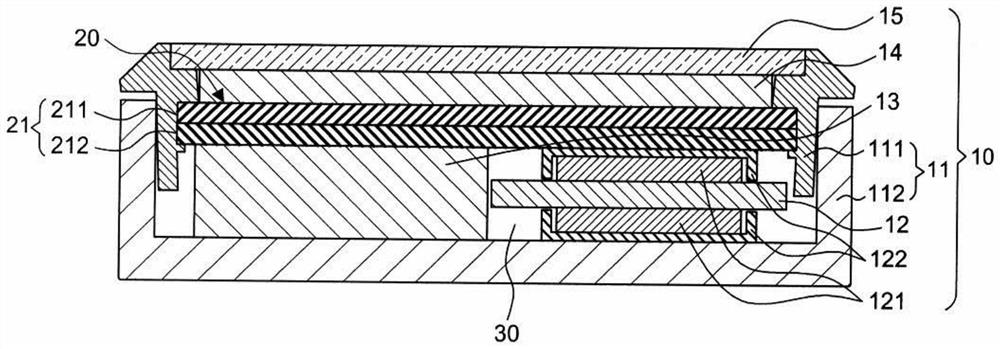

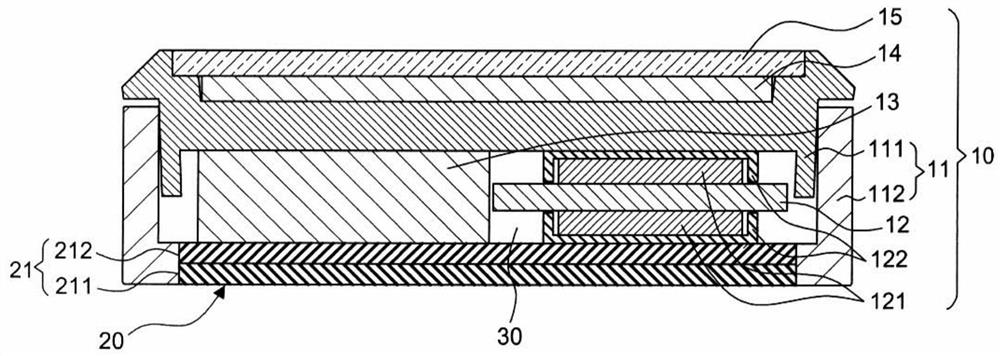

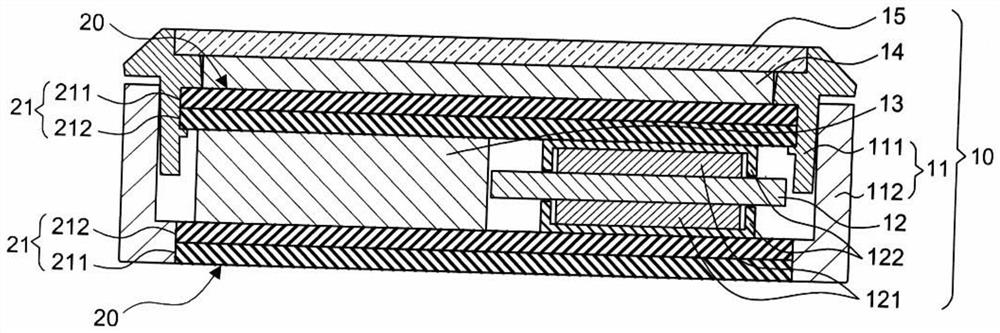

[0038] First, see Figure 1 ~ Figure 3 and Figure 4A , Figure 4B As shown, a preferred embodiment of a composite supporting heat dissipation structure of a portable electronic device of the present invention includes: a front case 111 and a rear case 112 suitable for the portable electronic device 10, and the front case 111 and the rear case 112 Correspondingly combined into a component 11, it is characterized in that: the front shell 111 and the rear shell 112 on the component 11 are at least integrally formed with a composite material 21 composed of two or more layers of different rigid materials 211, 212, Put the composite material 21 into a mold (plastic mold or die-casting mold) after stamping and molding, and form a complete body with a frame (plastic or metal) through injection molding, so that it becomes the main support of the front shell 111 and the rear shell 112 Body, forming a composite supporting heat dissipation structure 20, so that the front shell 111 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com