An in-mold injection molding heat dissipation coating structure capable of carrying an electronic device

A technology for heat-dissipating coatings and electronic devices, which is used in electrical equipment structural parts, electrical components, cooling/ventilation/heating renovation, etc. Good quality, good human-machine experience, and the effect of solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

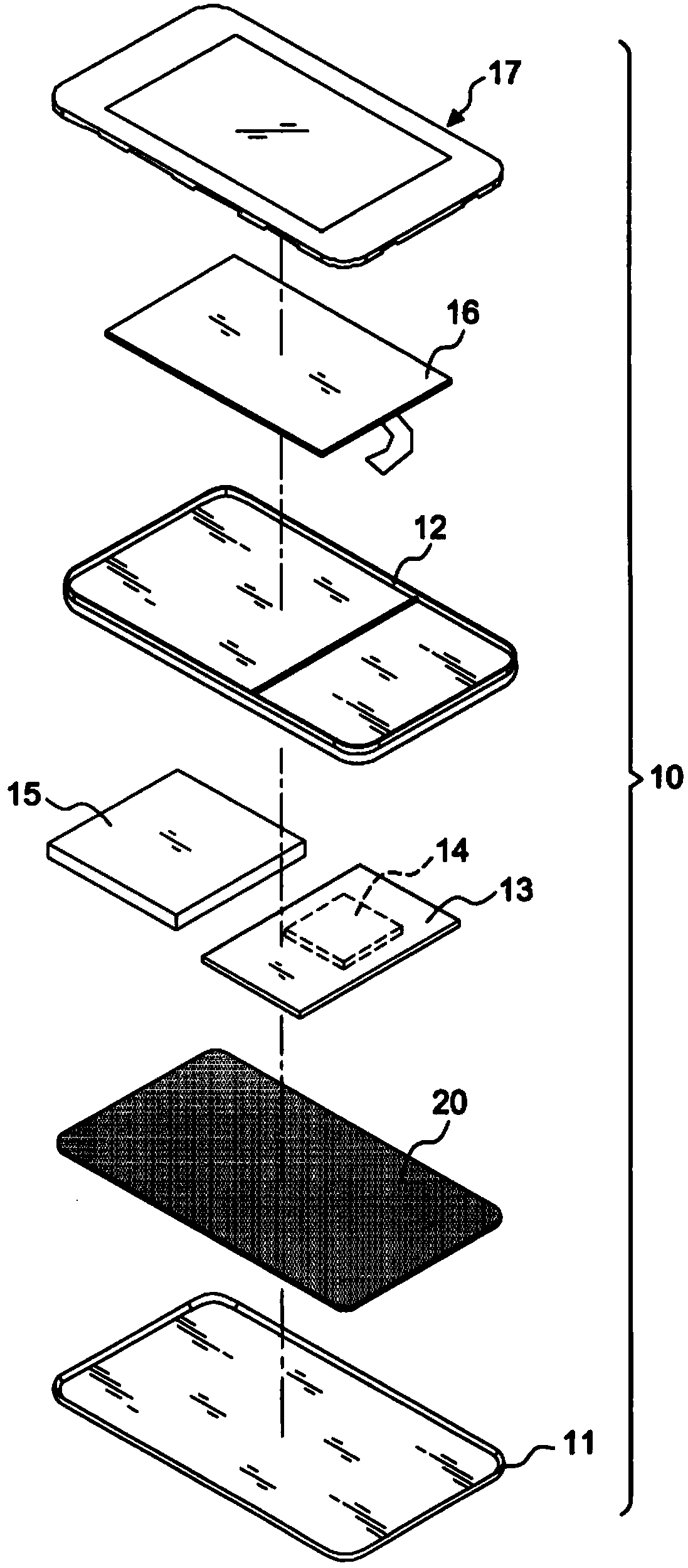

[0047] First, see Figure 2 to Figure 8 As shown, the in-mold injection-molded heat dissipation coating structure of the portable electronic device 10A of the present invention includes a rear case 11 combined with a front case 12, and the front case 12 and the rear case 11 are combined into a component 19 correspondingly, and in The rear shell 11 and the cavity 18 of the front shell 12, and the top surface of the front shell 12 are provided with predetermined electronic components, in this embodiment, the electronic components include the rear shell 11 and the front shell 12 Between the circuit board 13 and the battery 15 , the circuit board 13 has a core component 14 , and the electronic assembly also includes a display module 16 and a touch panel 17 disposed on the top surface of the front case 12 . However, the above-mentioned structure is the main component of the portable electronic device, which belongs to the prior art (Prior Art), which is not the purpose of this pate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com