Building with multifunctional rope reeling-off equipment

A multi-functional, equipment-based technology, applied in life-saving equipment, fire rescue, building rescue, etc., can solve problems such as difficulty in functioning of fire-fighting aerial ladders, incomplete fire-fighting facilities, and inability of fire-fighting aerial ladder vehicles to lift and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

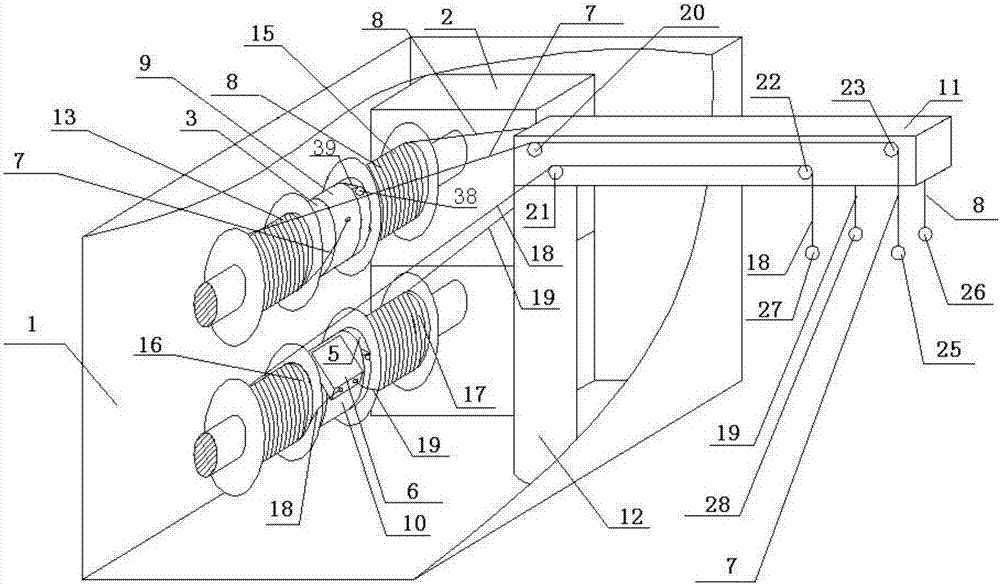

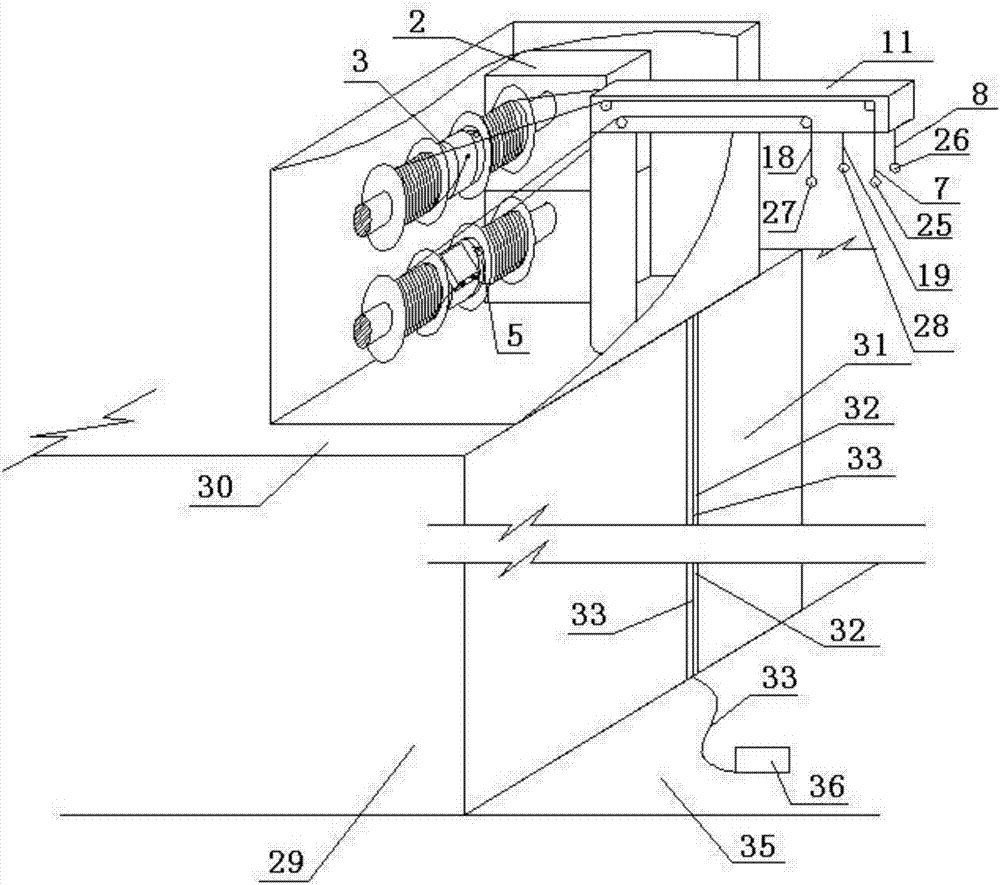

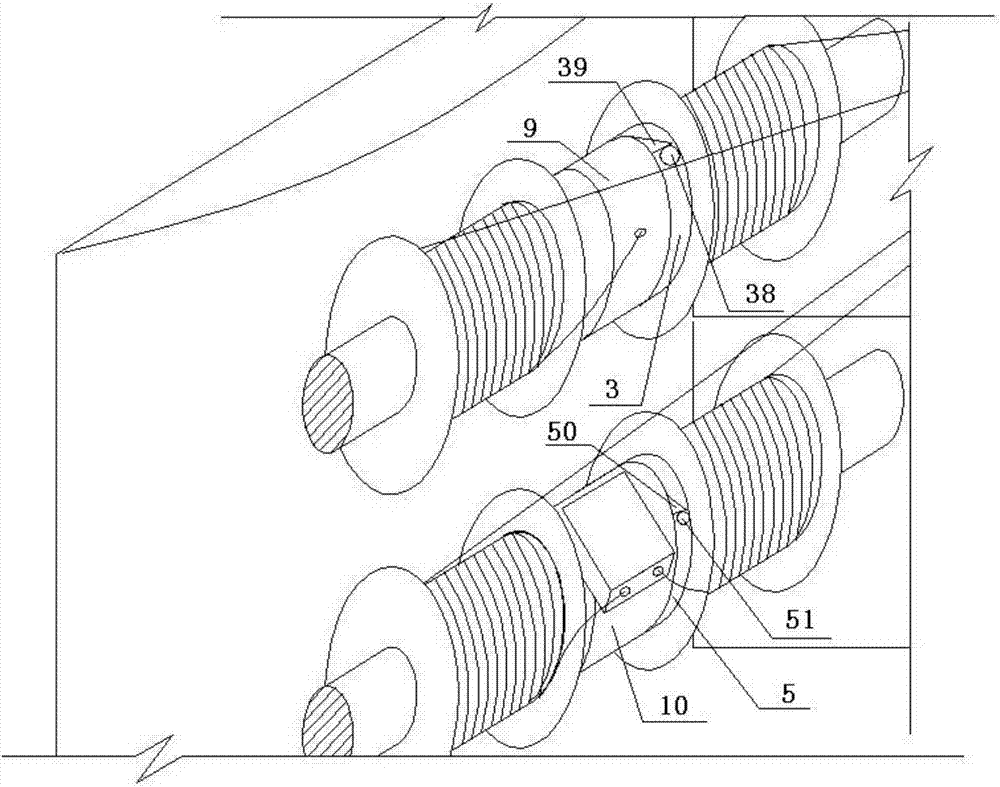

[0066] Such as figure 1 as shown, figure 1 It is a schematic oblique view of the multifunctional rope releasing device according to the first embodiment of the present application. The multifunctional rope-releasing device includes a housing 1, a motor 2, a reel 3, a reel 5, a descender 6, a stay rope 7, a stay rope 8, a ring 9, a ring 10, a cantilever 11, and a column 12, Above-mentioned motor 2, reel 3, reel 5, descender 6, stay cord 7, stay cord 8, annulus 9, annulus 10, column 12 are arranged in the housing, motor 2 and reel 3, reel 5 The connection can drive the reel 3 and the reel 5 to rotate. The above-mentioned ring 9 is set on the outer periphery of the reel 3 and can rotate around the reel 3. The above-mentioned ring 10 is set on the outer periphery of the reel 5 and can rotate around the reel 5. The above-mentioned descending device 6 is arranged on the ring 10 , and one end of the above-mentioned stay rope 7 is fixedly connected to the ring 9 . The above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com