Automatic spraying device for electric porcelain insulator

An automatic spraying and insulator technology, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of uneven spraying and drying, low work efficiency, and lack of spraying of electric porcelain insulators, etc., to achieve the invention Strong performance, avoiding missed spraying, improving spraying efficiency and drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

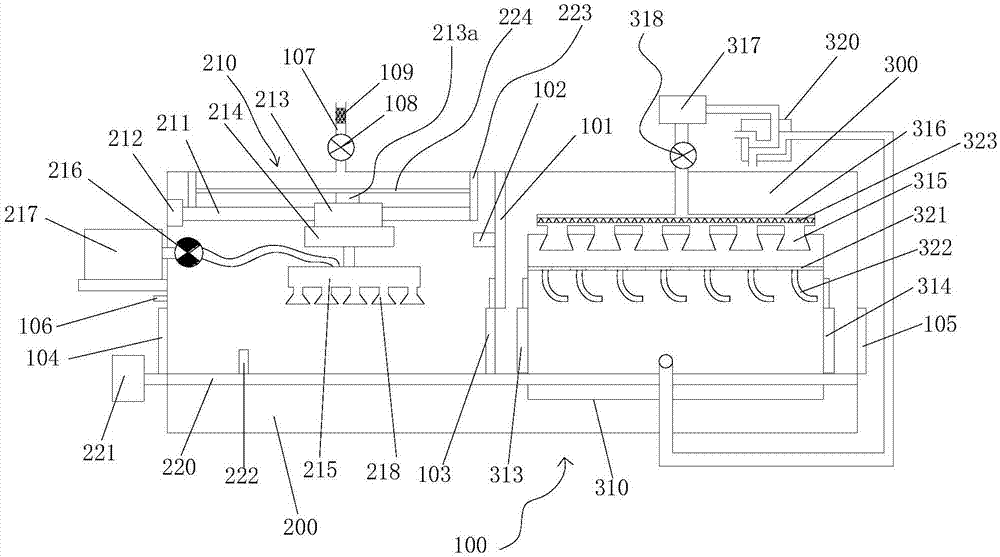

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0020] Such as figure 1 As shown, an automatic spraying device for electric porcelain insulators includes a device body 100, and the device body 100 is divided into a spraying chamber 200 and a drying chamber 300 by a vertical partition 101; the upper part of the spraying chamber 200 is provided with a spraying mechanism 210, the spraying mechanism 210 includes a horizontal guide rail 211, the guide rail 211 is a screw structure, the guide rail 211 is driven by a servo motor 212, and the guide rail 211 is provided with a sliding seat 213 that moves along the guide rail 211, The sliding seat 213 is provided with a swing cylinder 214, the output shaft of the swing cylinder 214 is fixed with a spraying chamber 215, and the spraying chamber 215 is connected to the metering pump 216 through a telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com