Molding device for metal pipe machining

A technology for forming devices and metal pipes, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as high equipment cost, failure to meet production progress and development progress, and long time period of pipe bending molds. Small size, reduced production time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

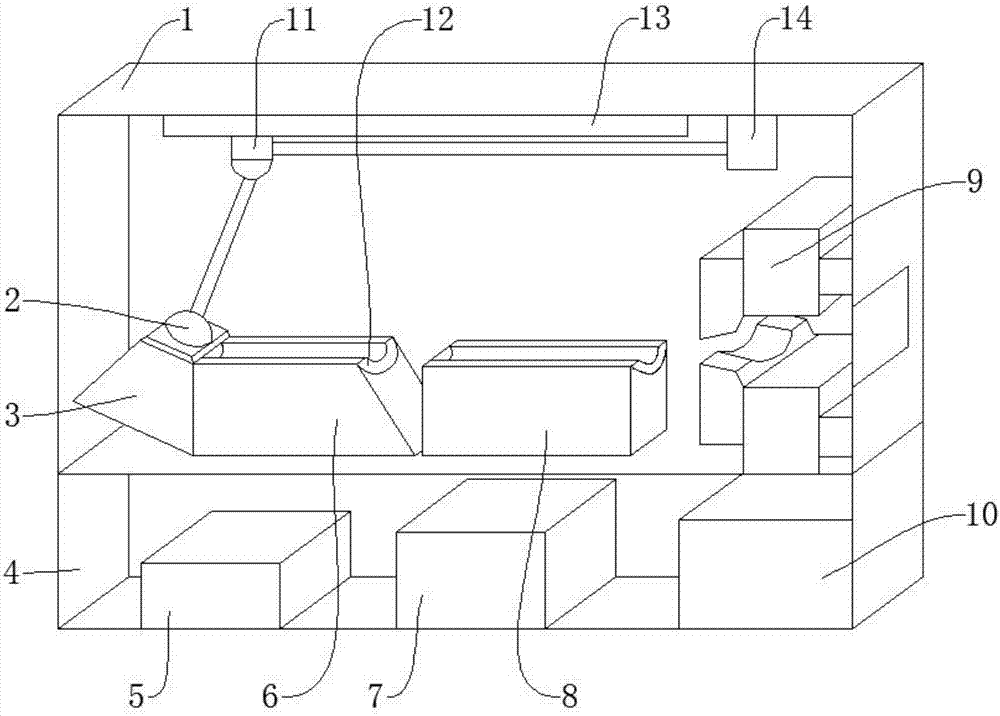

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

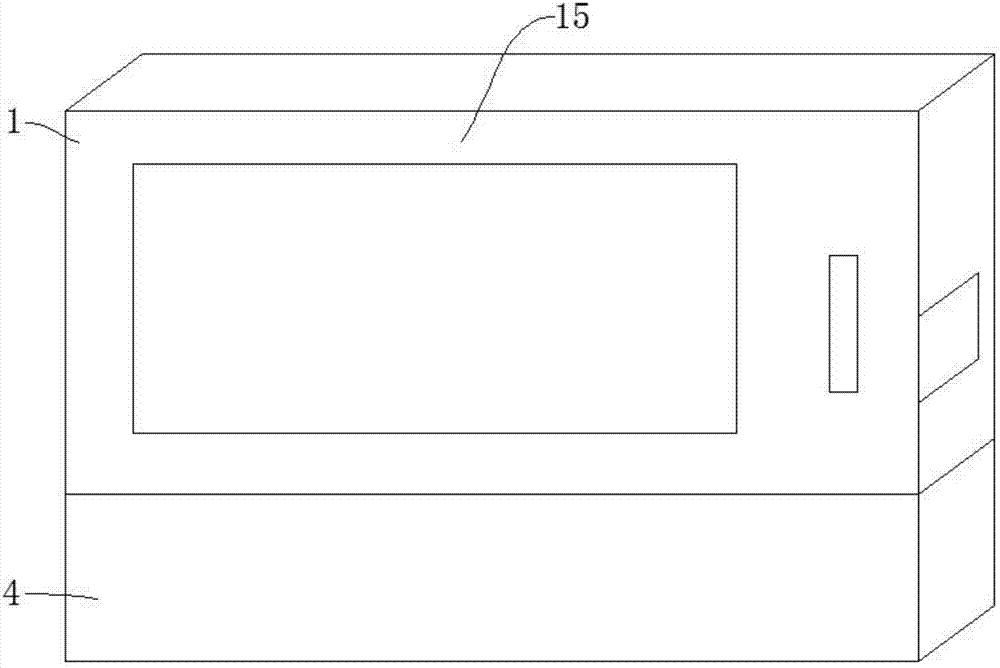

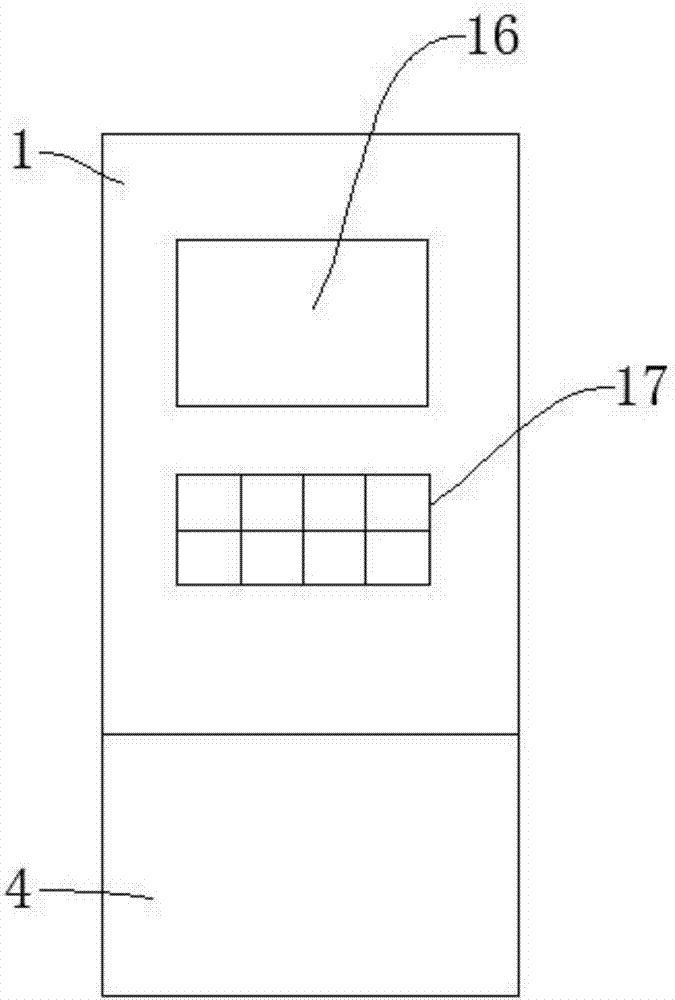

[0020] like Figure 1-Figure 3 As shown, a forming device for metal pipe processing includes a box body 1, a clamping hydraulic cylinder 9, a base 4, a slide rail 13, and a display screen 16. The bottom of the box body 1 is provided with a base 4, and the base 4 is used to support the equipment , the base 4 is provided with an oil tank 10, the oil tank 10 is used to hold hydraulic oil, a hydraulic pump 7 is installed on one side of the oil tank 10, the hydraulic pump 7 is used to provide power, and the other side of the hydraulic pump 7 is installed with a hydraulic valve 5, The hydraulic valve 5 is used to control the hydraulic pump 7, a box door 15 is installed at the front end of the box body 1, the box door 15 is used to take out the pipeline, and a display screen 16 is installed on the side of the box body 1, and the display screen 16 is used to display the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com