Welding positioning tool and pressure testing method for inner oil path type piston rod

A technology for welding positioning tooling and piston rod, which is applied in welding equipment, auxiliary welding equipment, fluid tightness testing, etc. It can solve the problems of stability and other problems, so as to achieve the effect of simple and clear pressure test process, improved pressure test efficiency and simplified welding operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

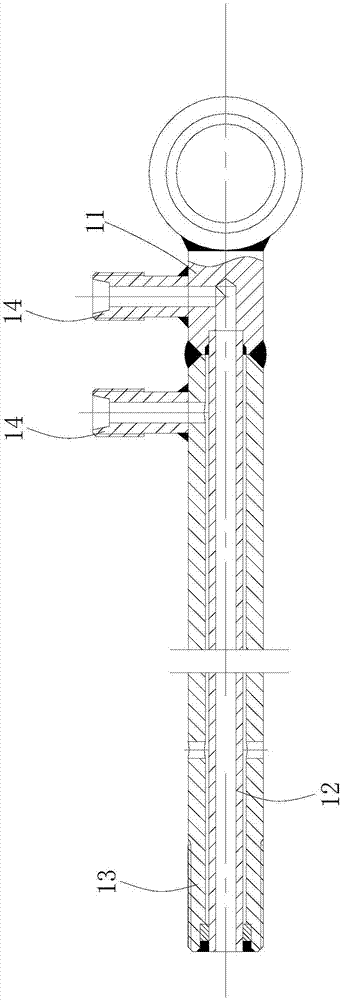

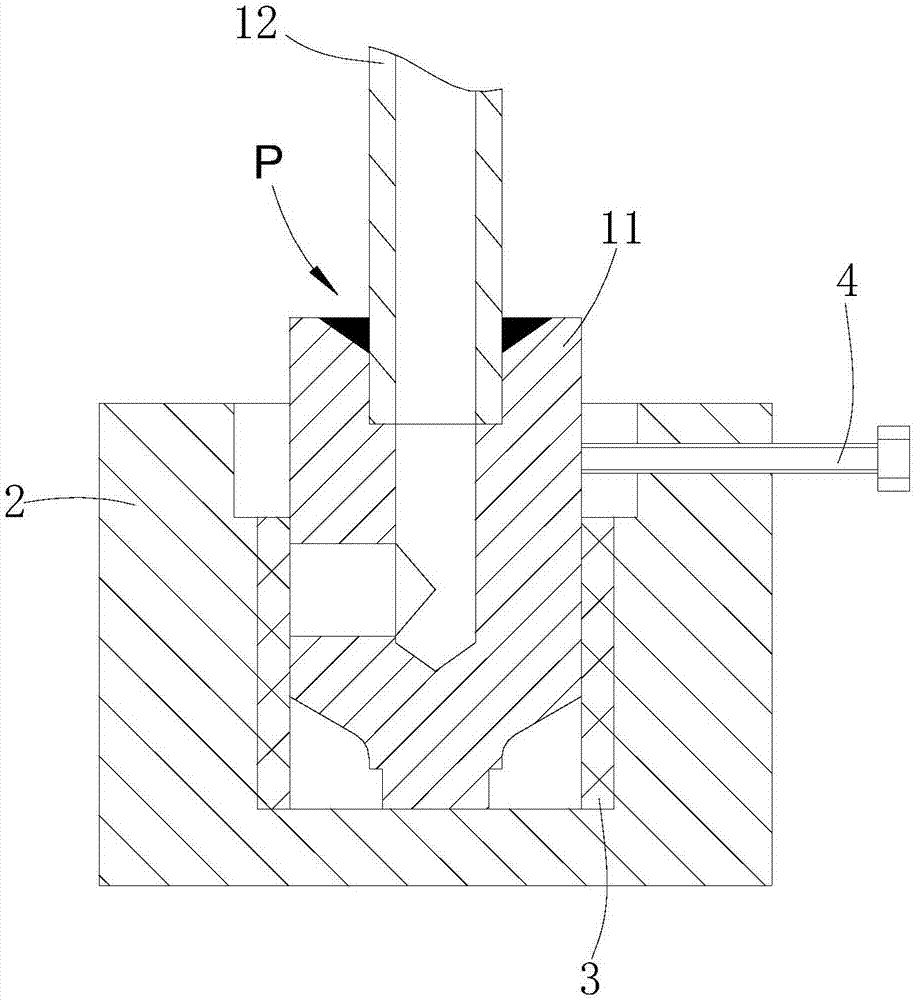

[0023] like Figures 3 to 4 shown

[0024] The positioning tooling includes a fixed seat 2, a limit bolt 4 and a sealing ring 3.

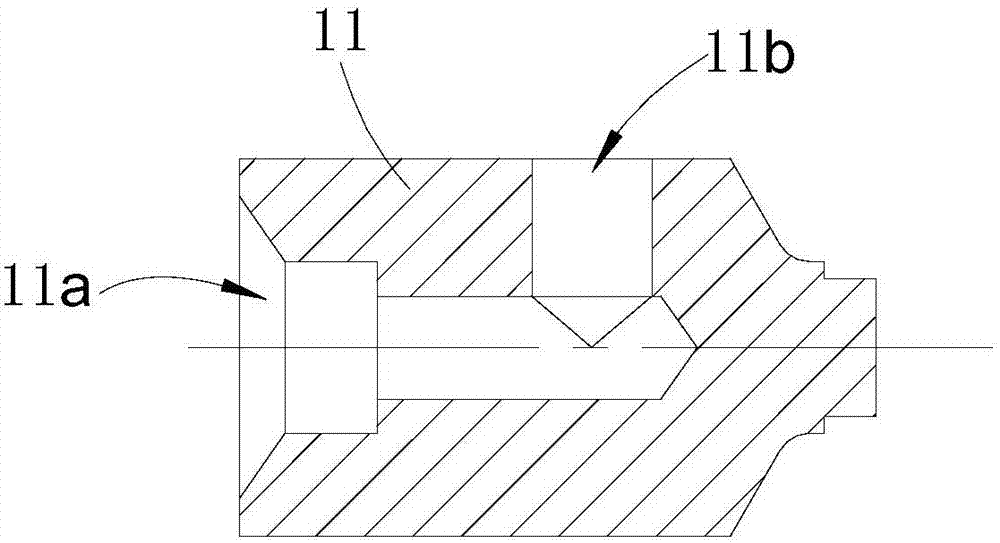

[0025] The fixed seat 2 is generally cylindrical, and the upper end surface of the fixed seat 2 is provided with a positioning groove that cooperates with the piston rod head 11. The positioning groove is a two-stage stepped groove, and the positioning groove is the first stage groove 21 and the second stage groove from top to bottom. Two-stage groove 22, the diameter of the first-stage groove 21 is greater than the diameter of the second-stage groove 22;

[0026] The side wall of the fixed seat 2 is provided with a limiting threaded hole (not shown) communicated with the first-stage groove 21, and the sealing ring 3 is set in the second-stage groove 22, and the height of the sealing ring 3 set is the same as that of the second-stage groove. 22 in the same width.

[0027] When the rod head 11 of the internal oil circuit type piston rod is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com