Automatic assembling device for eyeglasses frame

An automatic assembly and spectacle frame technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low assembly efficiency, high cost, and unprotected eyes, so as to improve survival efficiency, reduce production costs, and reduce The effect of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

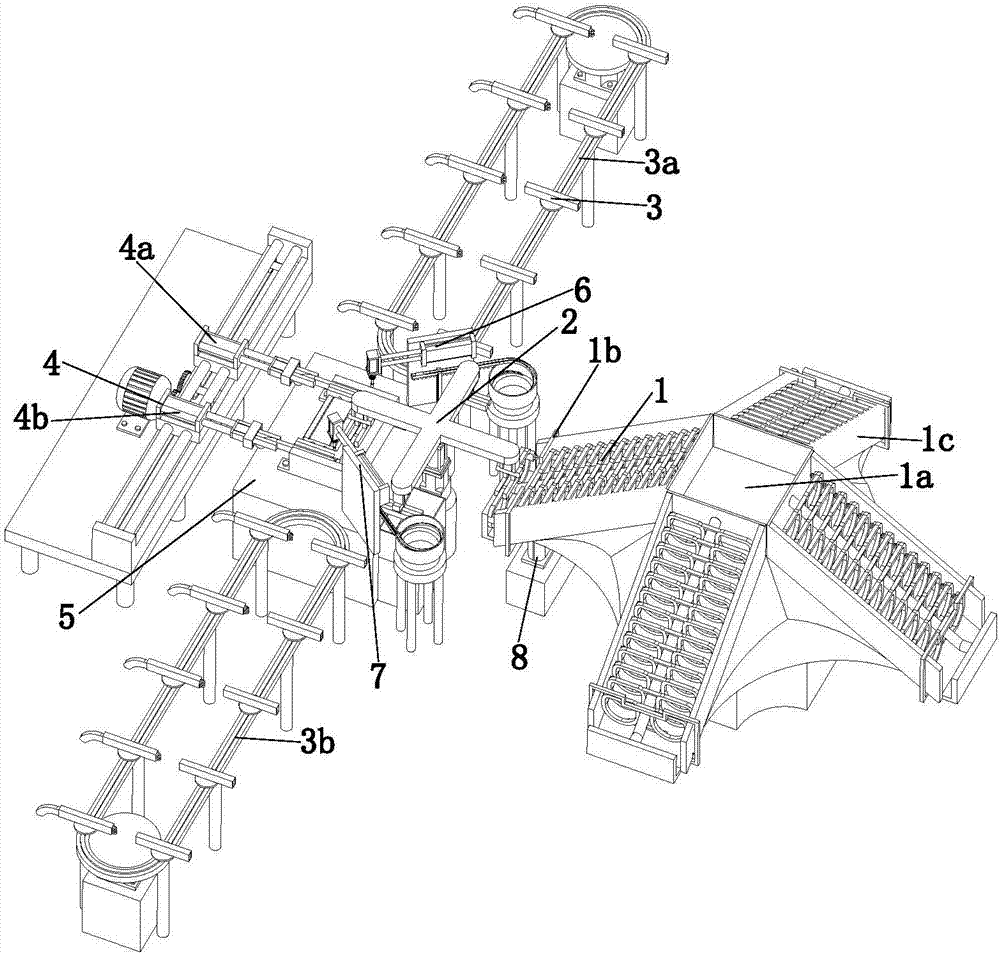

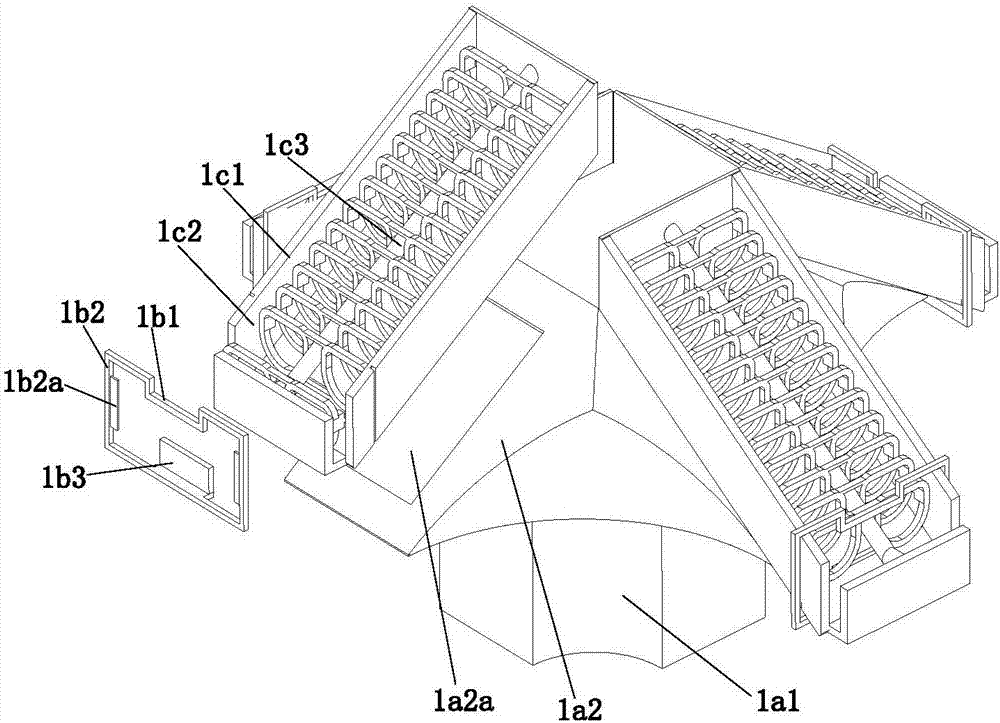

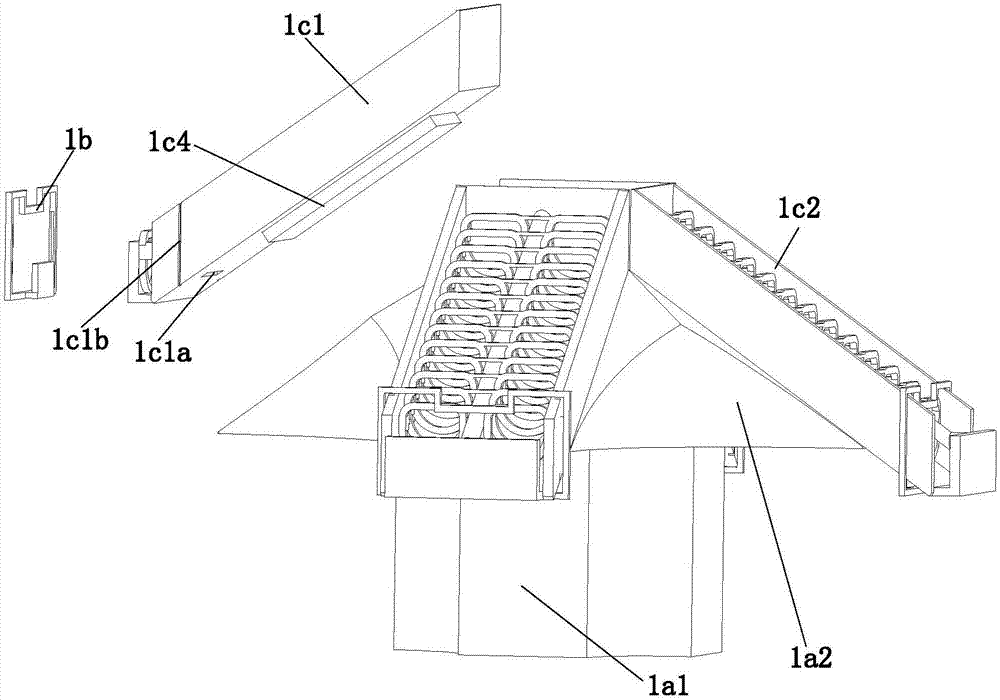

[0027] refer to Figure 1 to Figure 9The shown automatic assembly equipment for spectacle frames includes a spectacle frame feeding device 1, a spectacle frame transfer device 2, a spectacle pin feeding device 3, a spectacle pin positioning device 4, a workpiece table 5, a first assembling device 6 and a second assembling device Device 7, the frame feeding device 1, the frame transfer device 2, the mirror pin feeding device 3, and the mirror pin positioning device 4 are all located on the side of the workpiece table 5, and the first assembly device 6 and the second assembly device 7 are symmetrical Be arranged on the side of the workpiece table 5, the workpiece table 5 is provided with a workpiece seat 5a fixedly connected with the workpiece table 5, the workpiece seat 5a is provided with a U-shaped workpiece groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com