Compounding and cutting integrated machine

An all-in-one machine and composite machine technology, applied in the field of technical processing, can solve problems such as waste of raw materials, product color difference, and affect the quality of clothing, and achieve the effects of simplifying production and processing technology, saving time and cost, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0021] The first embodiment of the present invention is to provide a composite cutting machine, the purpose of which is to effectively integrate the use of the composite machine and the cutting machine, simplify the production and processing process, have a simple structure, be easy to operate, save time and cost, and reduce wrinkles.

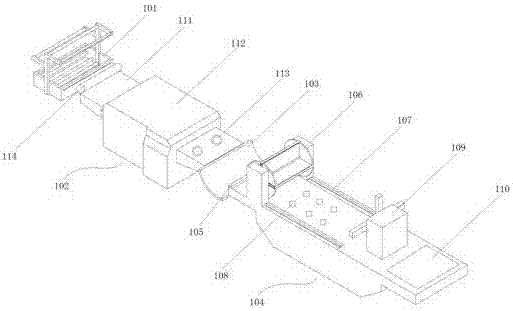

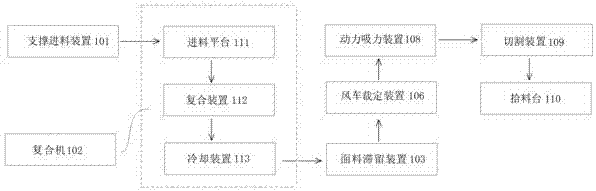

[0022] Such as figure 1 As shown, a composite cutting integrated machine includes a supporting feeding device 101, a composite machine 102, a fabric retention device 103, and a cutting table 104 connected in sequence, wherein the cutting table 104 is sequentially provided with a tension control device from left to right 105. Windmill ruling device 106, drive moving device 107, power suction device 108, cutting device 109 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com