Pumpkin single cell juice preparation method and its products

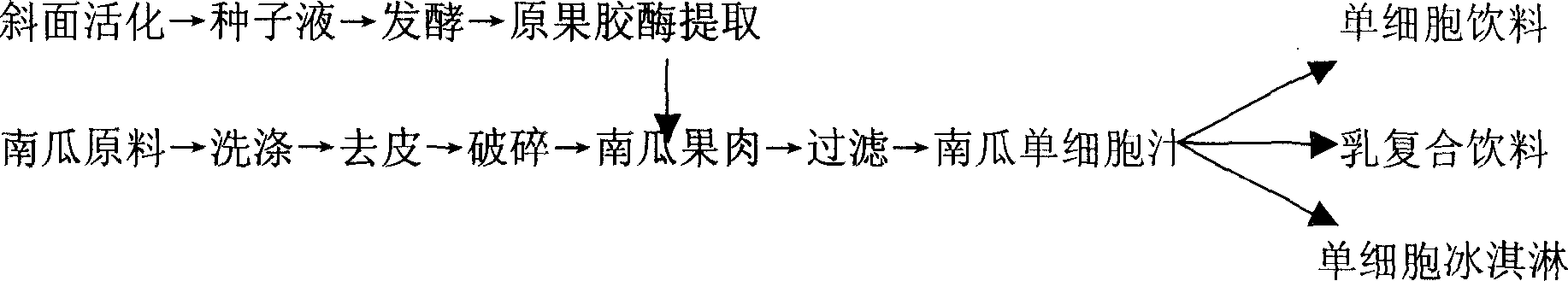

A single-cell and pumpkin technology, applied in food science and other directions, can solve problems such as pumpkin single-cell juice and its compound beverages that have not yet been seen, and achieve the effect of maintaining nutritional value and health care efficacy, cell integrity, and reducing the pressing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After the Aspergillus sp.Z-25 bacterial strain (Journal of Radiation Research and Radiation Technology, 2005, 23 (3): 140-144) is activated, it is inserted into the seed tank according to the ratio of 1-10% of the culture solution volume of the seed tank, and 25- 32°C, cultivated for 24-48 hours, then inoculated into the fermenter according to the proportion of 3%-15% of the seed liquid volume, 25-32°C, fermented for 48-84 hours, centrifuged or filtered the fermented liquid to remove the bacteria, and The supernatant was precipitated with 40-80% saturated ammonium sulfate, and an appropriate amount of citric acid was added to dissolve the precipitate, decolorized and deodorized with activated carbon, filtered with a microporous membrane to obtain propectinase, and stored at 4°C for future use.

[0024] Choose high-quality pumpkins with high maturity, good freshness, and no mildew and deterioration as raw materials, wash with water to remove the dirt on the surface of the...

Embodiment 2

[0026] Pumpkin single-cell juice was prepared according to the method in Example 1. The pumpkin single-cell juice is blended with auxiliary materials such as sucrose and citric acid, the sugar content is 10-12% (m / V), the xanthan gum is 0.10-0.2% (m / V), and the guar gum is 0.30-0.4% (m / V), β-cyclodextrin is 0.4-0.6% (m / V), pumpkin single-cell juice is 20-30% (V / V), acidity (calculated as citric acid) is 0.22% (m / V) ). The prepared slurry is degassed under the condition of vacuum degree ≥ 0.05Mpa to remove the oxygen in the original slurry, and then pasteurized at 60-80°C, then hot-filled, sealed, and quickly cooled to produce into a single-cell beverage containing pumpkin. After inspection, it can be packaged and put into storage.

Embodiment 3

[0028]Pumpkin single-cell juice was prepared according to the method in Example 1. The pumpkin single-cell juice is blended with raw materials such as milk and sucrose, and the formula is: pumpkin single-cell juice 10-20 (V / V), milk 30-40% (V / V), sugar content 6-8% (m / V), sodium carboxymethylcellulose (CMC) 0.2-0.25% (m / V), propylene glycol alginate (PGA) 0.1-0.15% (m / V), guar gum 0.03-0.07% (m / V) V), citric acid 0.2~0.25% (m / V). The prepared slurry is subjected to homogenization treatment under the condition of 20Mpa, then pasteurized at 60-90°C, and then hot-filled, cooled and sealed to prepare the compound milk drink containing pumpkin single cells. After inspection, it can be packaged and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com