Conductive busbar

A technology of busbars and convex ribs, which is applied in the field of rail transit, can solve the problems of difficult installation, slight movement of high and low points of busbars, and error-prone problems, so as to achieve simple and convenient installation of intermediate joints, elimination of slight movement of high and low points, and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

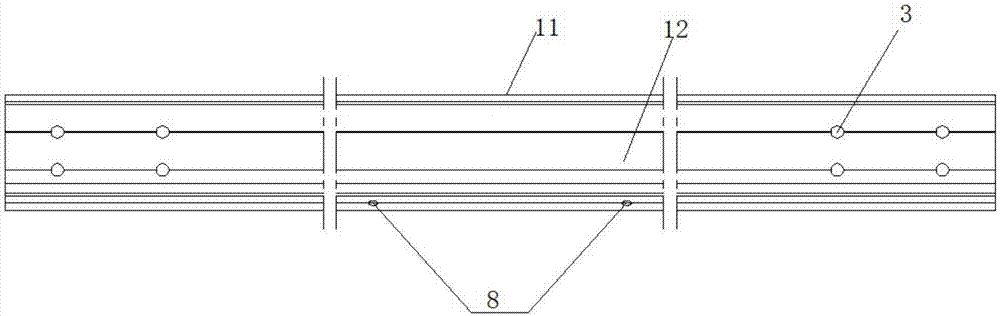

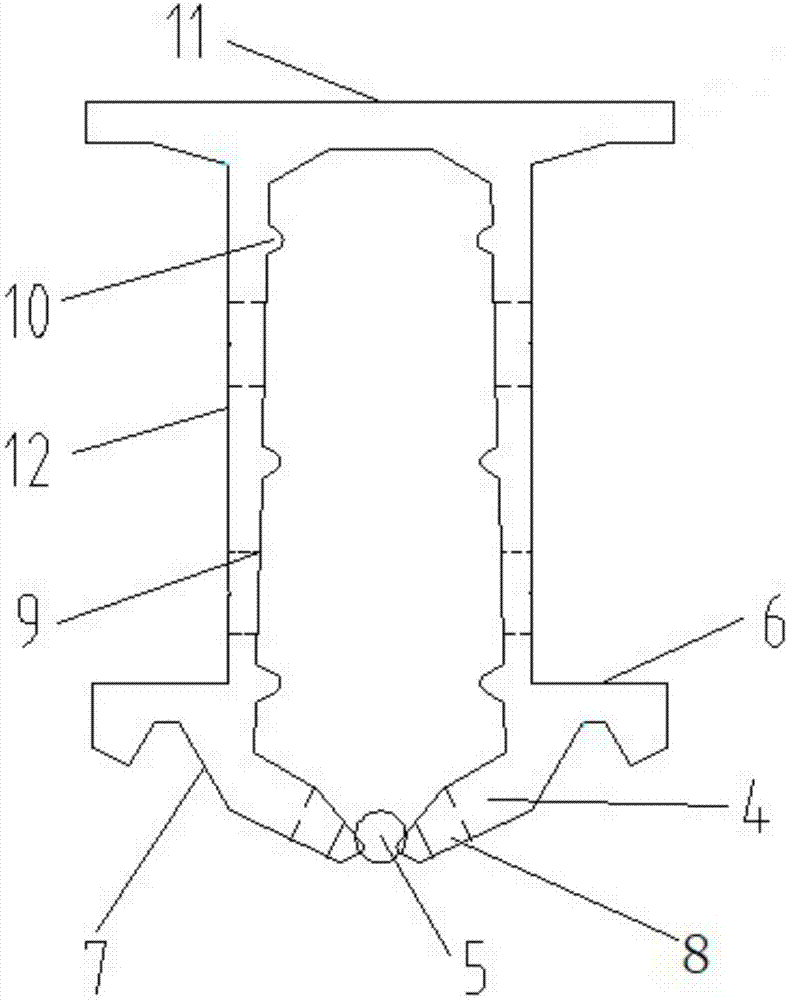

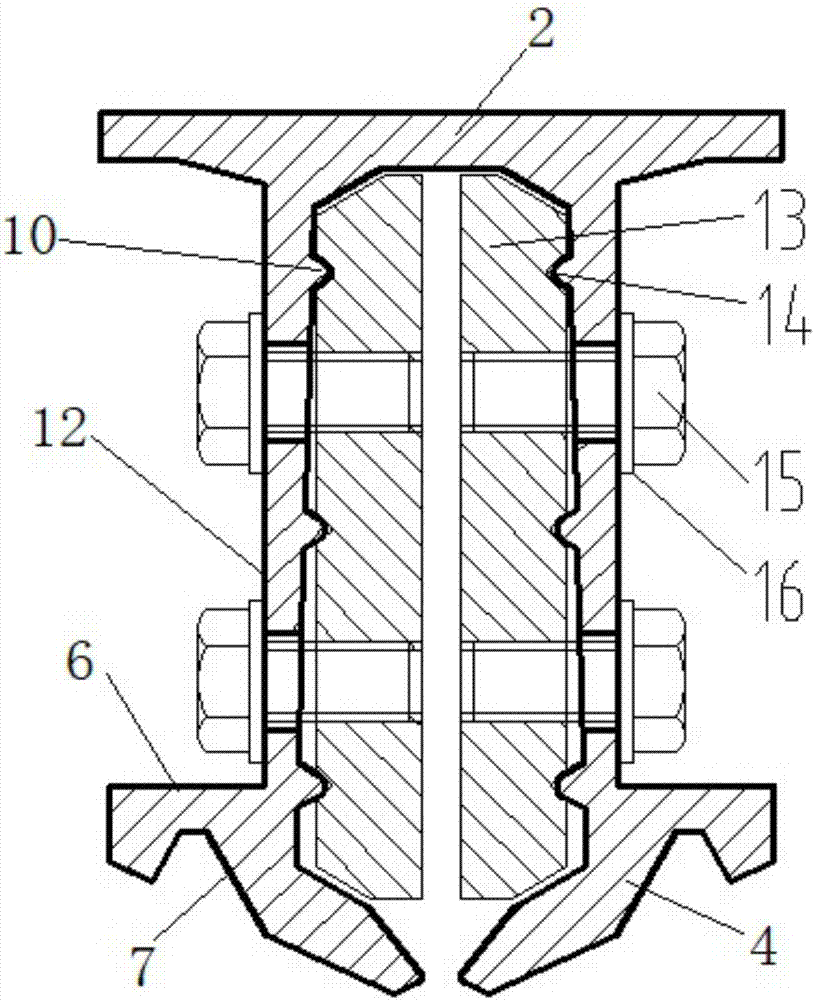

[0019] like figure 1 , figure 2 As shown, a conductive bus bar includes a top 11, a pair of side walls 12 are symmetrically extended below the top 11, and clamps 4 are arranged under each side wall 12, and the ends of the clamps 4 are formed between the ends for clamping. The elastic jaws of the contact wire 5 are provided with three ribs 10 from top to bottom on the opposite surfaces of the two side walls 12 , and the two ends of each side wall 12 are provided with connection ports 3 . Each chuck 4 extends horizontally with a trolley running platform 6, which is convenient for the operation of a special-purpose embedding trolley. V-shaped grooves 7 are arranged below each trolley running platform 6, which is convenient for embedding and thread removal of the embedding trolleys. Each V-shaped groove surface is provided with two pairs of symmetrical drain outlets 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com