Electric power-assisted brake system with brake pedal completely separated from power-assisted mechanism

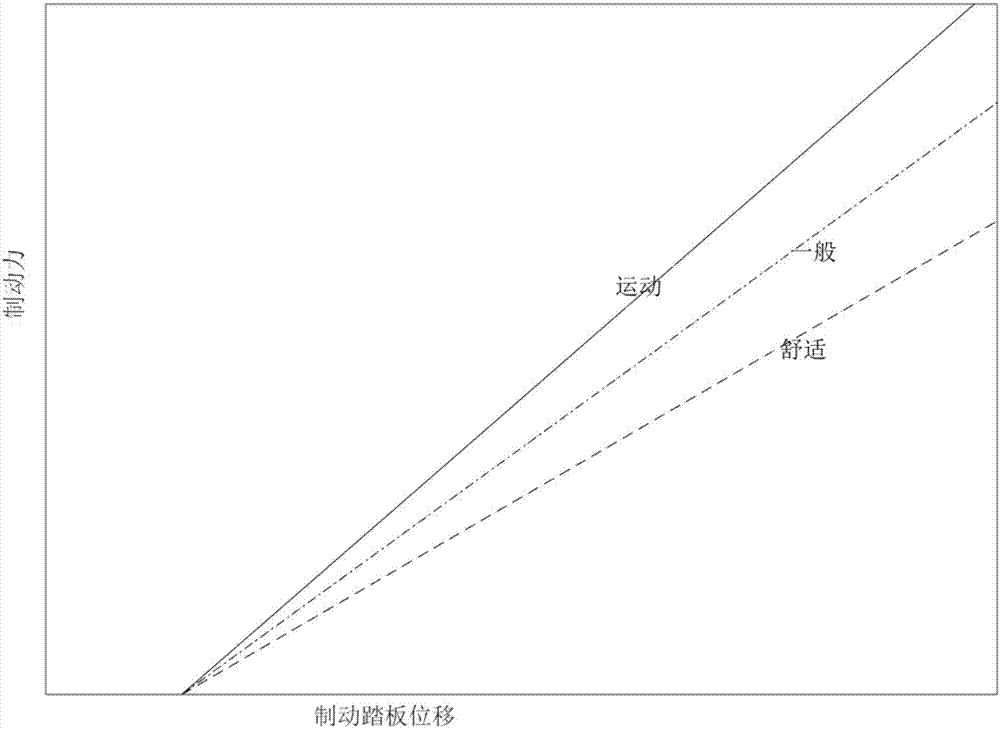

A technology of brake pedal and electric power assist, which is applied in the direction of brake transmission device, brake, foot start device, etc. It can solve the problems of large size of transmission pair, complex control algorithm, poor pedal feeling retention, etc., and achieve transmission ratio The effect of large size, compact size and simple control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

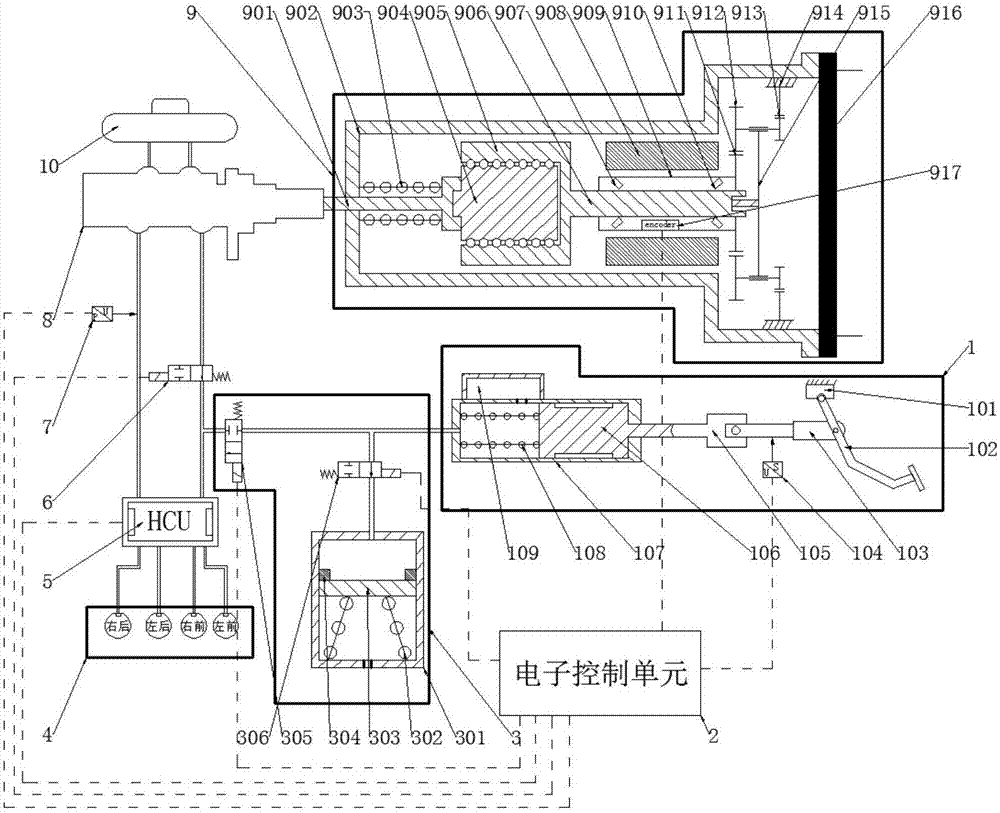

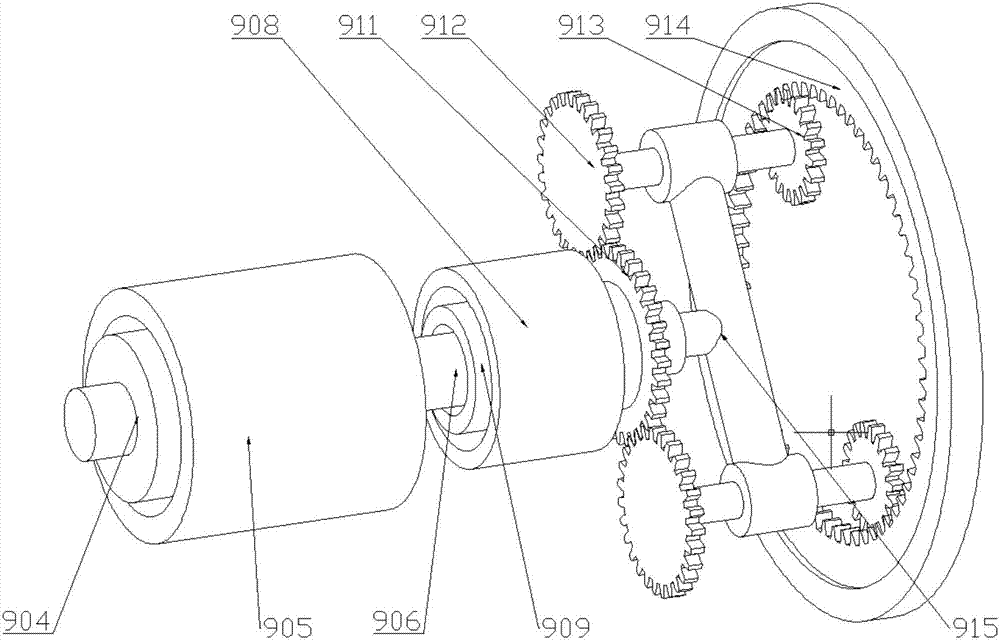

[0027] An electric power-assisted braking system in which the brake pedal and the power-assisted mechanism are completely separated, comprising: a braking intention generation unit 1, an electronic control unit 2, a pedal feeling simulator 3, a wheel cylinder 4, an HCU 5, a third solenoid valve 6, Hydraulic pressure sensor 7, master cylinder 8, liquid storage tank 10, electric power assist assembly 9.

[0028] An electric power-assisted braking system in which the brake pedal and the power-assisted mechanism are completely separated, and the braking intention generation unit 1 includes a rotating shaft bracket 101, a brake pedal 102, a pedal push rod 103, a pedal displacement sensor 104, and a piston push rod 105 , Piston 106, piston cylinder 107, piston return spring 108, liquid storage chamber 109. Wherein, the top of brake pedal 102 is connected with rotating shaft bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com