Automatic glove collecting intelligent system and method

An automatic collection and intelligent system technology, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve problems such as inflexibility, occupation of production space, and reduction of worker stand rate, so as to achieve flexible and reliable operation, save production space, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

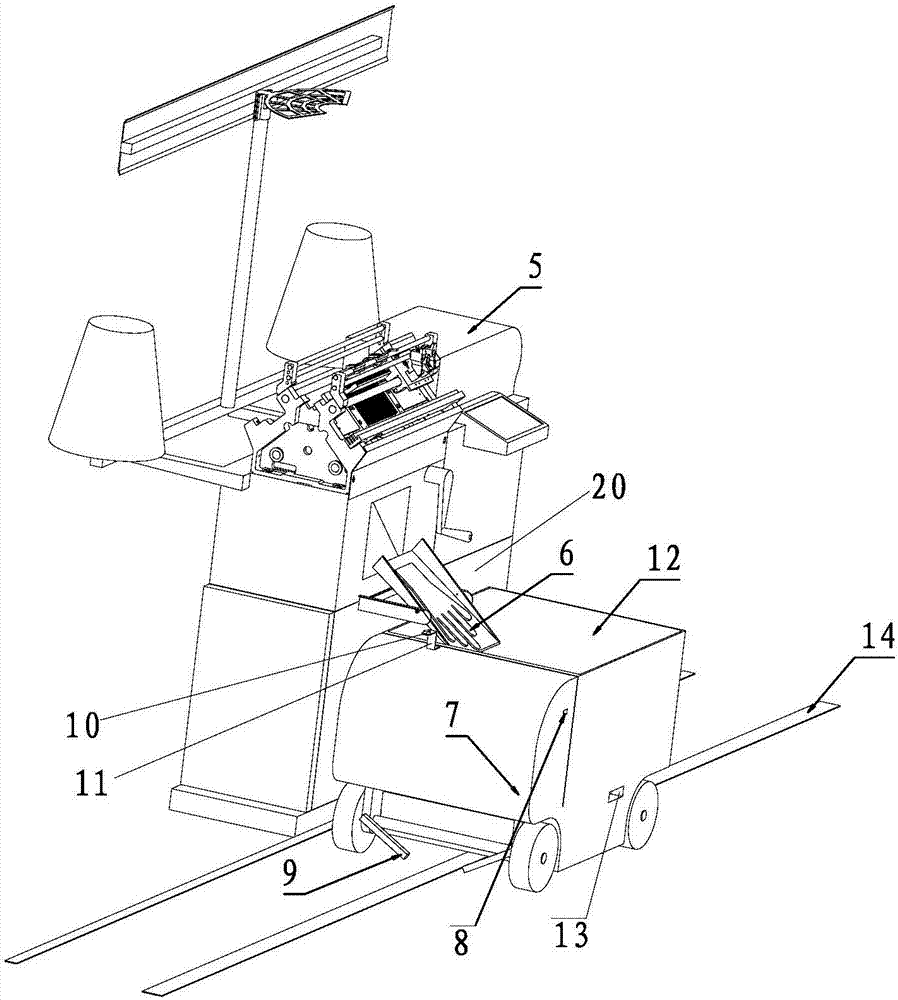

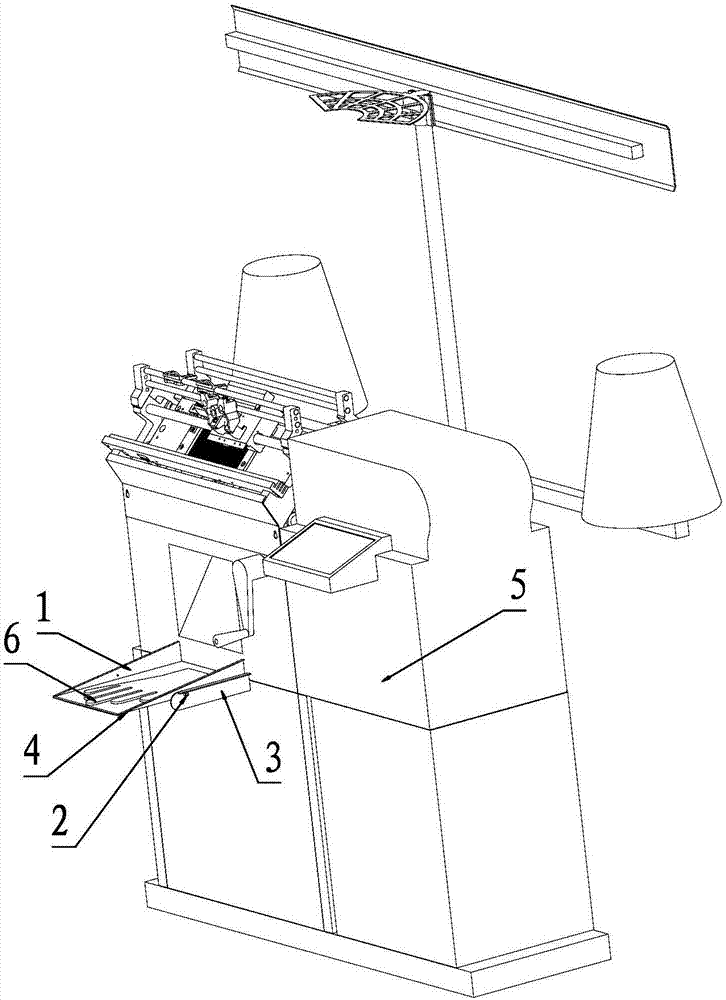

[0022] Such as Figure 1-2 As shown, a glove automatic collection intelligent system includes an overturning mechanism 20 installed on the glove knitting machine 5, a collecting cart 7, an induction guide rail 14 and a terminal control system; wherein, the overturning mechanism 20 is used in conjunction with the collecting cart 7, The collection vehicle 7 is located on the induction guide rail 14 to run, and the terminal control system is used to control the collection vehicle, so that the collection vehicle 7 can operate as required, and collect the gloves produced by each glove knitting machine 5 .

[0023] combine figure 1 Shown, the present embodiment collection car 7 is electric drive, can charge, and charging port 13 is established on the car. The collection car 7 moves along the induction guide rail 14 according to the set management program, and the input port 8 is established on the car. A pair of induction heads 9 left and right are installed under the headstock. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com