Slaughtering sewage treatment system with waste recycling function

A technology for slaughtering sewage and waste recycling, which is used in flotation water/sewage treatment, water/sewage multi-stage treatment, animal processing wastewater treatment, etc. Recycling and other issues to achieve the effect of improving efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

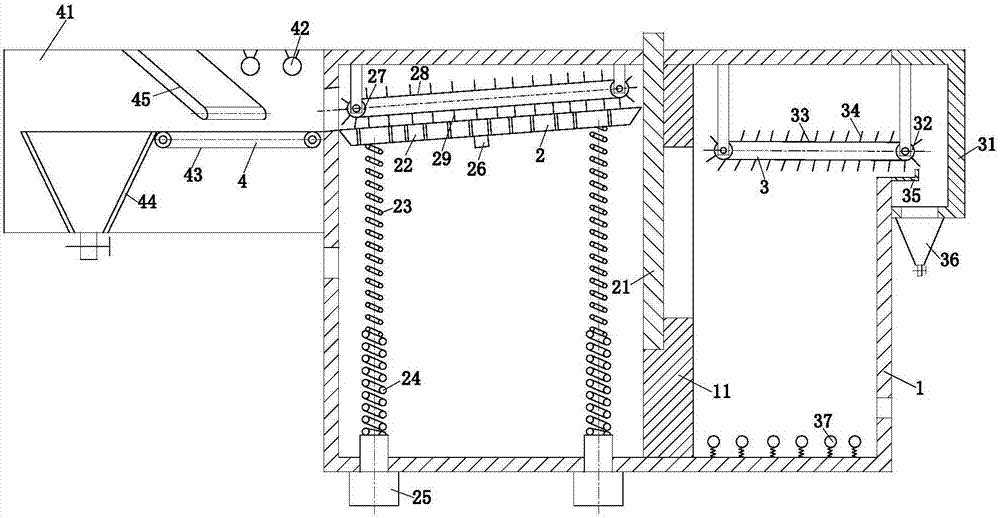

[0022] like figure 1As shown, a slaughter sewage treatment system with a waste recovery function according to the present invention includes a box body 1, a filter module 2, an oil removal module 3 and a screening module 4, and the inside of the box body 1 is provided with ribs 11, The rib plate 11 divides the interior of the box body 1 into two independent parts on the left and right. The left side is the filter chamber and the right side is the oil removal type. , the upper end of the groove passes through the top of the box body 1 to communicate with the outside world, the lower part of the left end surface of the box body 1 is provided with a water inlet, the upper part of the left end surface of the box body 1 is provided with a slag outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com