Steel reinforced concrete rectangular column and special-shaped column transfer frame structure

A frame structure and special-shaped column technology, applied in the field of conversion structure, can solve the problems of discontinuity between upper shear wall and bottom frame column, application limitation of commercial and residential complex buildings, interruption of vertical force transmission path, etc., and achieve good development prospects, Enhanced energy consumption and ensure a reasonable transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

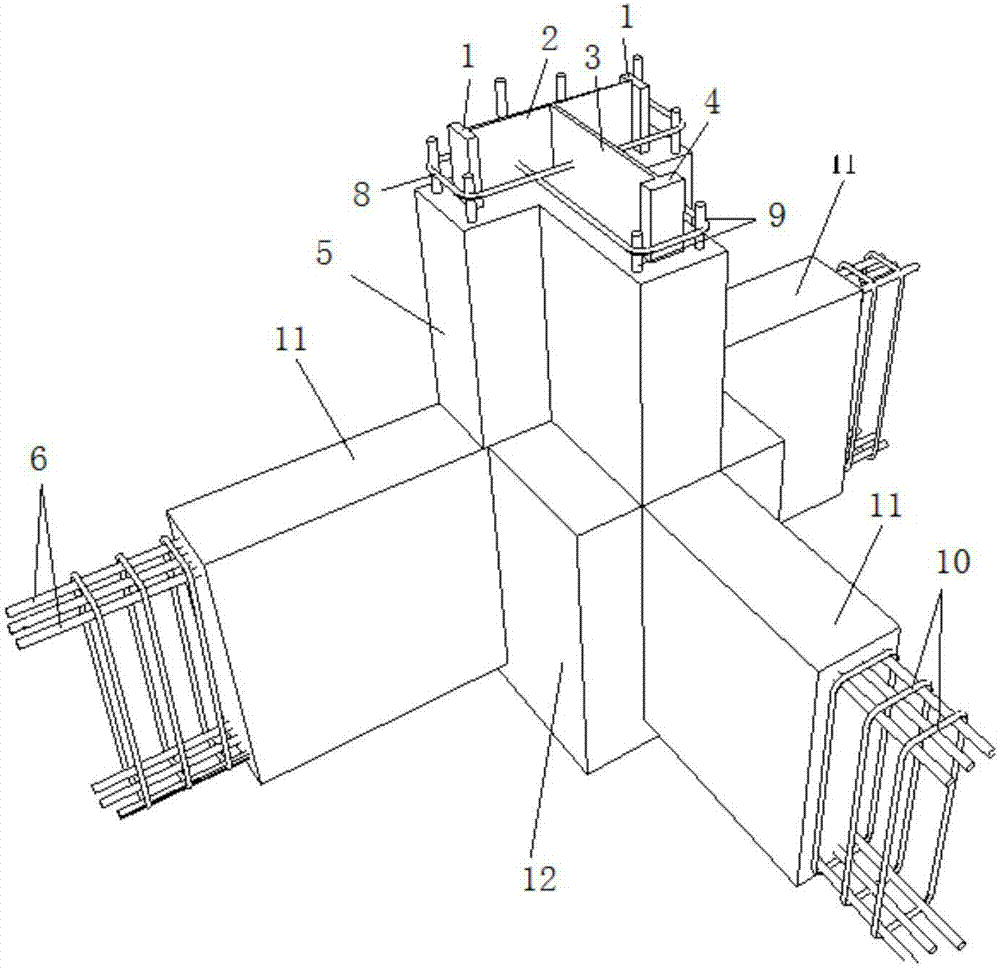

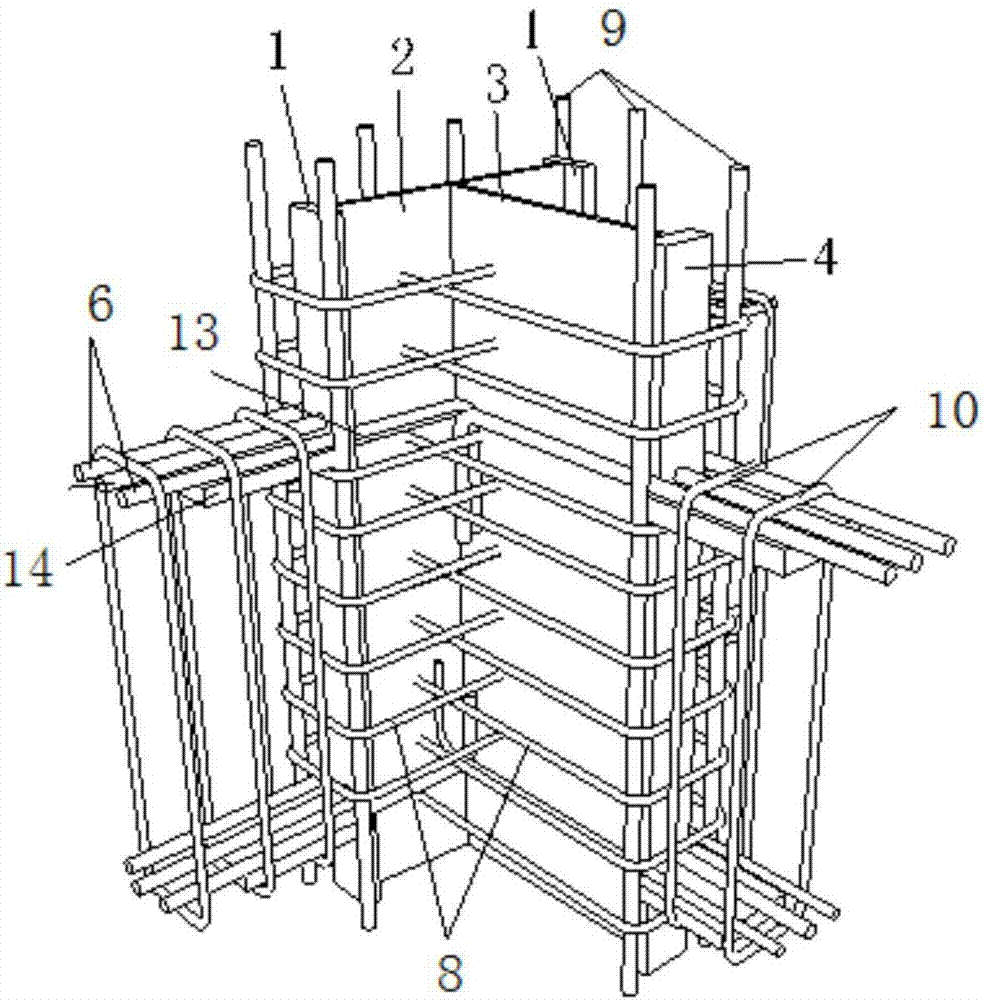

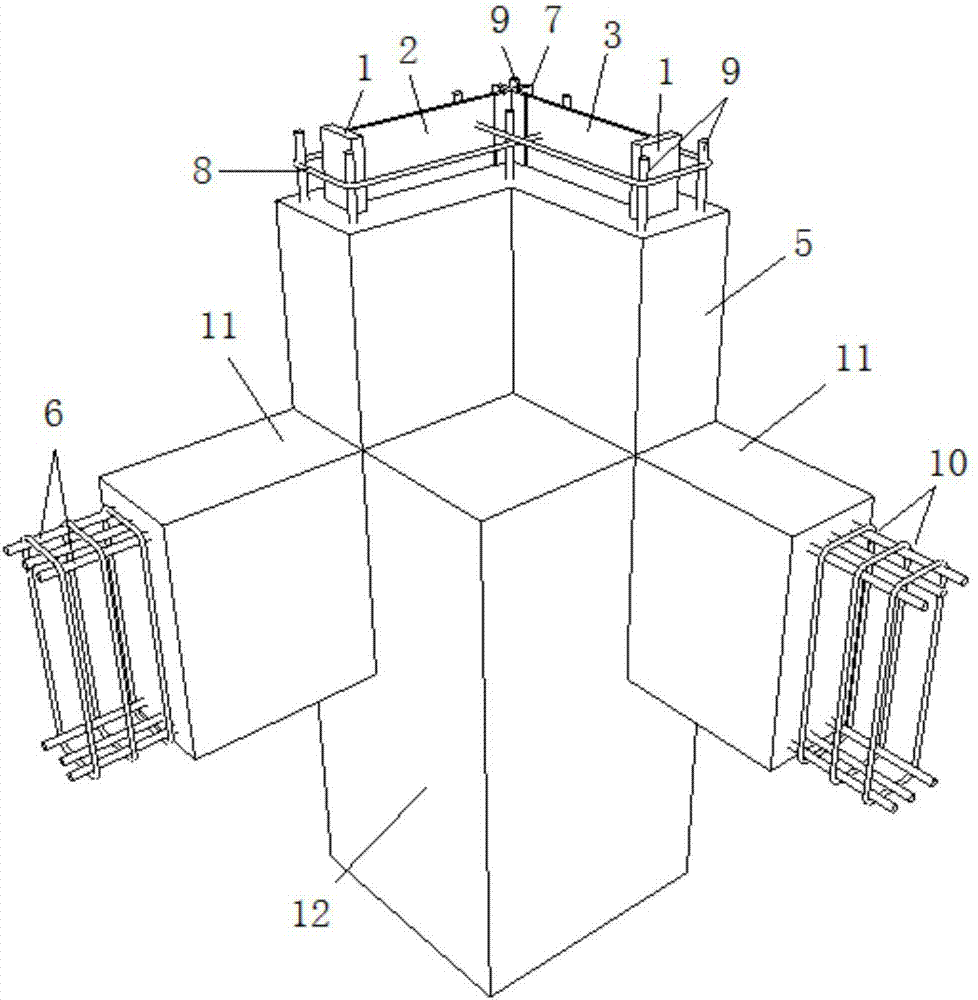

[0024] As shown in Figure 1(a), (b) and Figure 2(a), (b) and Figure 3(a), (b), a steel concrete rectangular column-special-shaped column conversion frame structure, including the bottom rectangular column 12. The concrete beam 11 connected with the rectangular column 12 at the bottom, the longitudinal reinforcement 6 of the beam runs through the concrete beam 11, and several stirrups 10 around the longitudinal reinforcement 6 of the beam; The same special-shaped column 5, the special-shaped column 5 is penetrated with T-shaped, L-shaped or cross-shaped steel along its longitudinal distribution, and along the periphery of the T-shaped, L-shaped or cross-shaped steel is provided with a central longitudinal column distributed along its longitudinal direction. The ribs 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com