Damping device and washing machine

A damping device and damping technology, applied in the field of washing machines, can solve the problems of damping force drop, hidden safety hazards, increased costs, etc., and achieve the effects of stable performance, low failure rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

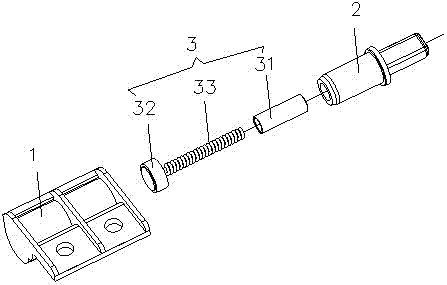

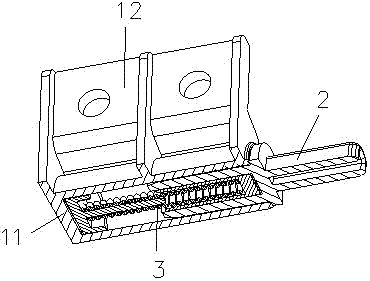

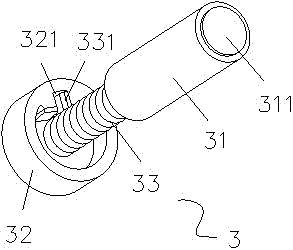

Image

Examples

Embodiment 1

[0069] In the first embodiment, the connecting hole on the upper cover 10 needs to be aligned with the connecting shaft extending hole on the control panel base 20, and the connecting shaft 21 of the rotating shaft 2 protrudes from the control panel base 20 and is engaged and fixed in the connecting hole. Thereby the upper cover 10 and the control panel base 20 are connected together; finally, the fixing base 12 and the control panel base are fixed with screws

[0070] In this embodiment, first extend the connecting shaft 21 of the rotating shaft 2 out of the protruding hole on the control panel base 20, fix the fixing base 12 and the control panel base 20 with screws, and then install the upper cover 10;

[0071] Specifically, the connecting shaft 21 is first pushed into the housing 1, and then the connecting hole on the upper cover 10 is aligned with the protruding hole on the control panel base 20, and the rotating shaft 2 is released, and the rotating shaft 2 protrudes unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com