Take-up device for wet thread drying machine

A wire take-up device and dryer technology, which is applied in drying, drying solid materials, and dry cargo handling, etc., can solve the problems of incomplete drying and wet wires, and achieve simple structure, convenient operation, and high drying efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

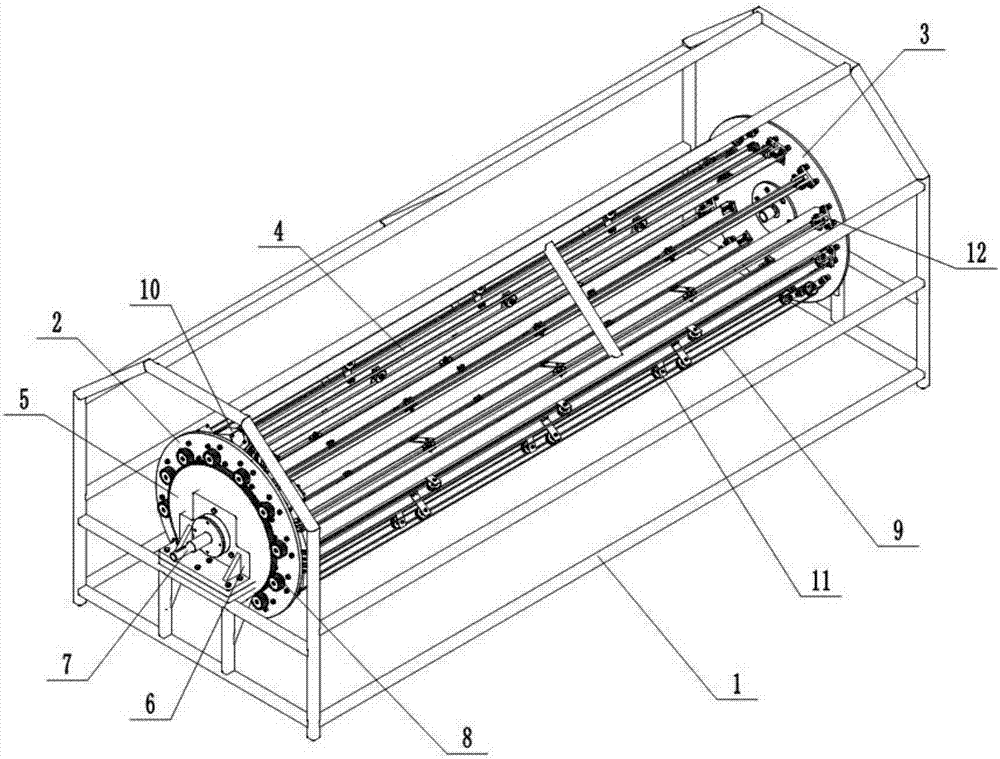

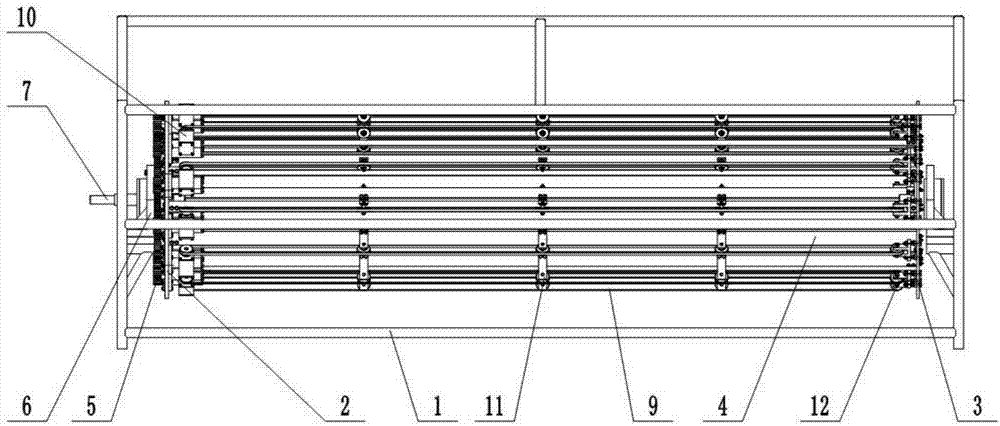

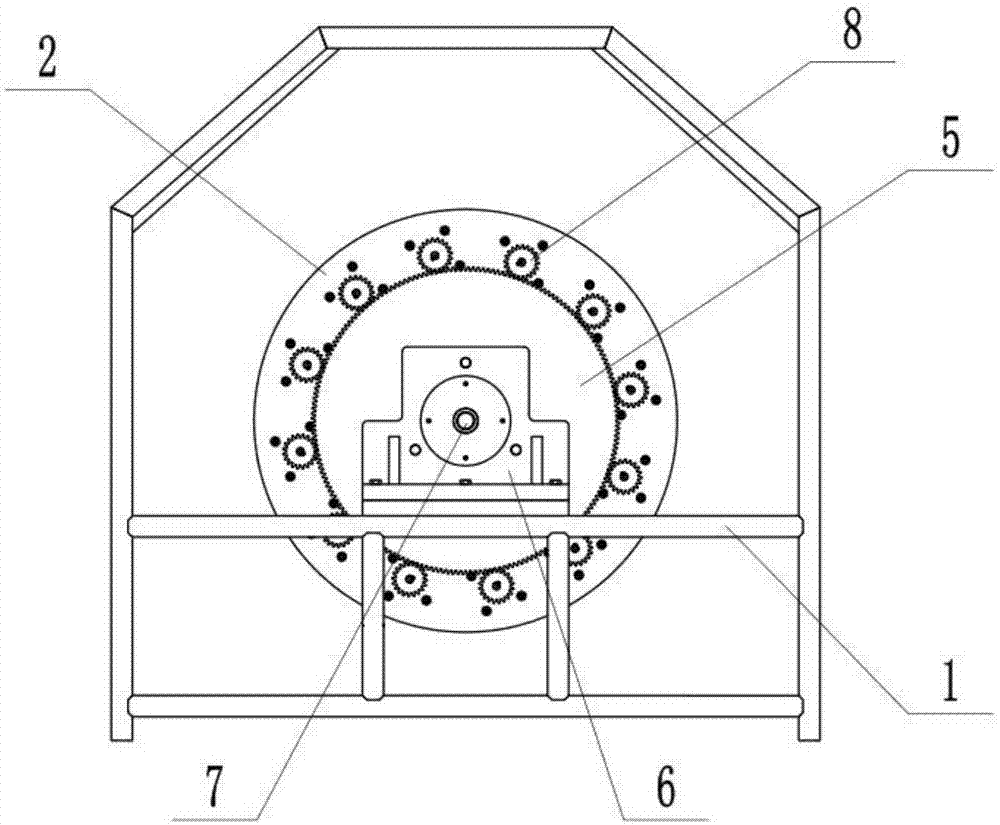

[0020] refer to Figure 1 to Figure 4 In this embodiment, a wire take-up device for a wet thread dryer includes a frame 1, a front end baffle 2 and a rear end baffle 3, and the front end baffle 2 and the rear end baffle 3 are respectively arranged in rotation through a bearing seat 6. On both sides of the frame 1, the front end baffle 2 is connected to the input shaft 7, and the input shaft 7 drives the front end baffle 2 to rotate, and the front end baffle 2 and the rear end baffle 3 are rigidly connected by cylindrical angle steel 4 arranged at intervals, A sun gear 5 parallel to the end surface of the front end baffle 2 is fixedly connected to the bearing seat 6 of the front end baffle 2, and a plurality of planetary gears 8 meshing with the sun gear 5 are arranged at intervals on the front end baffle 2, and the planetary gears 8 pass through The transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com