High-pressure sensor fault handling method and device

A fault handling method and high-voltage sensor technology, applied to measuring devices, instruments, heating methods, etc., can solve problems such as downtime, reduced customer experience, and temperature adjustment system paralysis, and achieve the effect of improving stability and enhancing customer experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

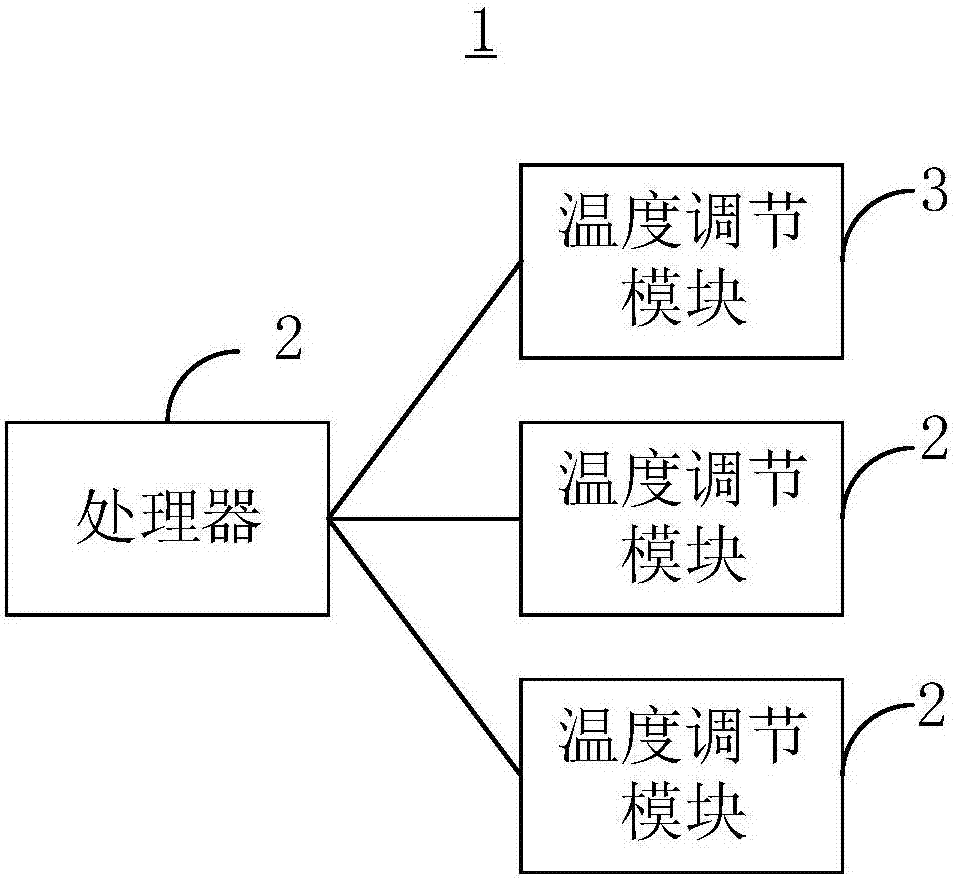

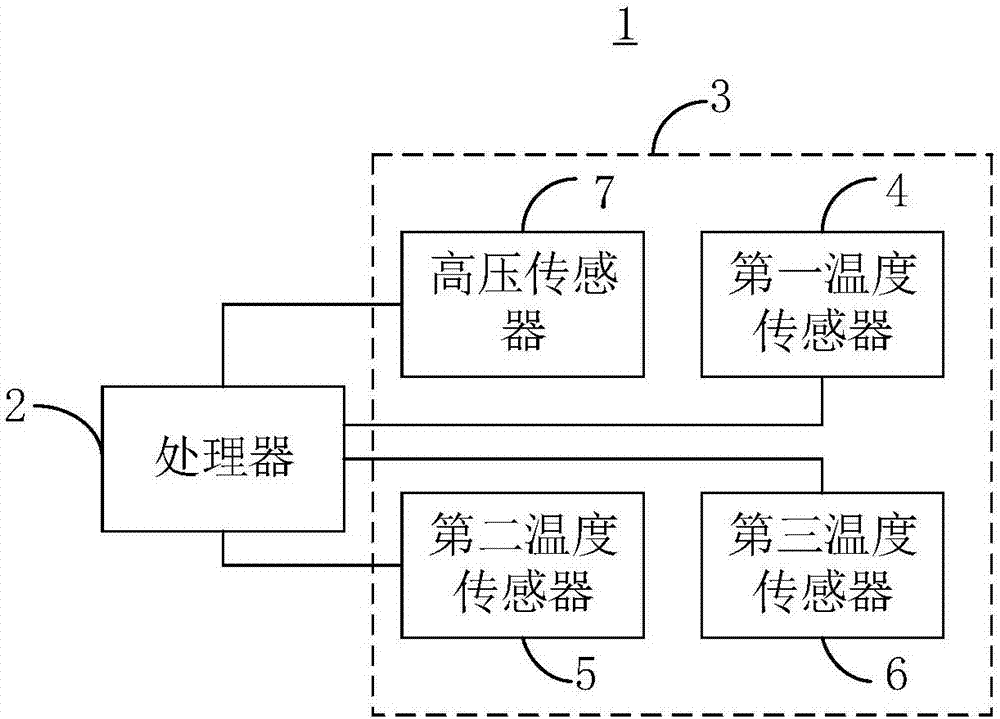

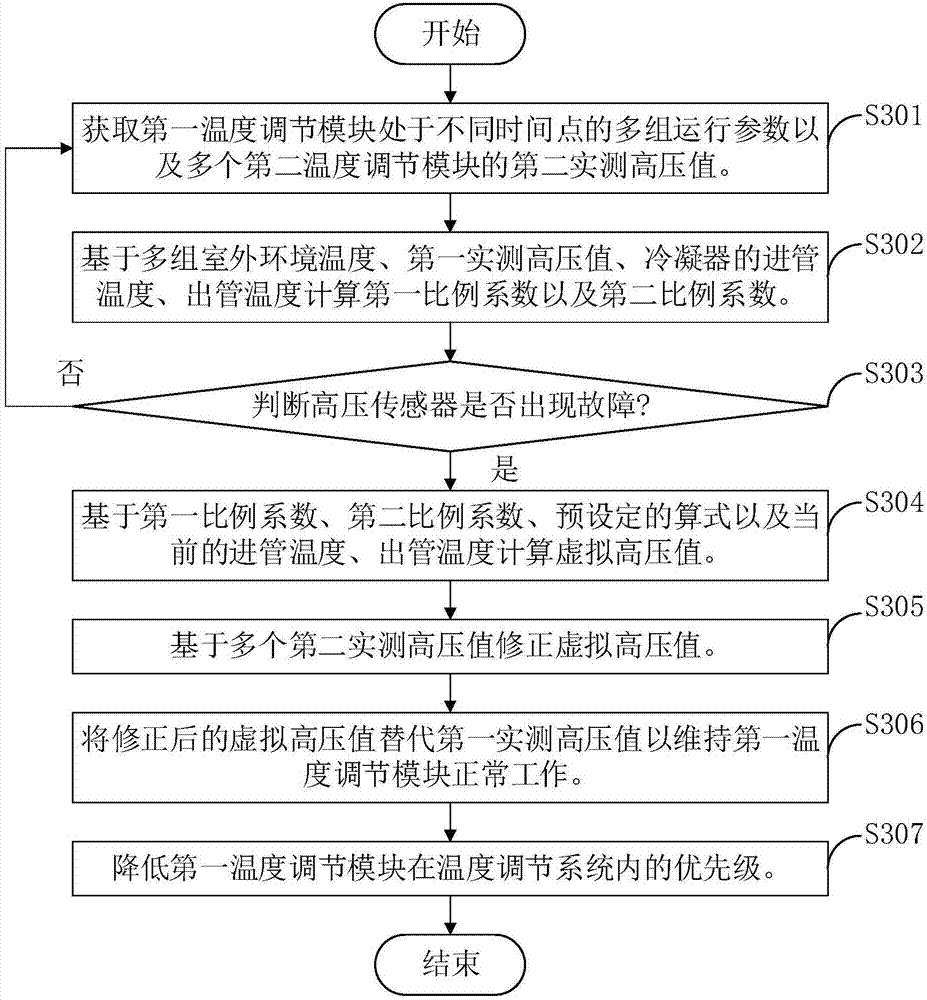

[0056] The embodiment of the present invention provides a high-pressure sensor 7 fault handling method, which is applied to the temperature adjustment system 1, and is used to replace the measured high-voltage value with the calculated virtual high-voltage value after the high-voltage sensor 7 fails, so that the temperature adjustment system 1 still continues to work normally. see figure 2 , is a flow chart of the method for troubleshooting the high pressure sensor 7 provided by the embodiment of the present invention. The high pressure sensor 7 troubleshooting methods include:

[0057] Step S301: Obtain multiple sets of operating parameters of the first temperature regulation module at different time points and second measured high pressure values of multiple second temperature regulation modules.

[0058] It should be noted that each set of operating parameters is used to reflect the operating state of the first temperature adjustment module when the set of operating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com