Novel partial-pressure mass spectrometer calibration device and method

A technology of calibration device and partial pressure, applied in the direction of measurement device, instrument calibration, measurement of fluid pressure, etc., can solve the problems of large measurement uncertainty of calibration results and inability to prepare gas according to actual needs, so as to reduce measurement uncertainty. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

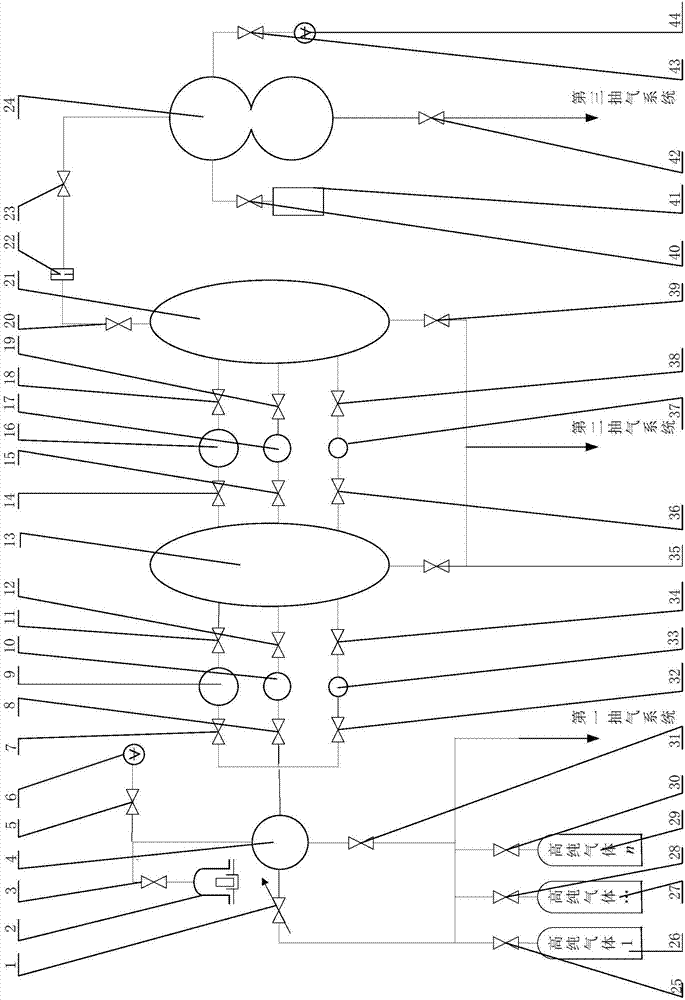

[0038] A new type of partial pressure mass spectrometer calibration device, mainly composed of fine-tuning valve 1, piston pressure gauge 2, sample preparation chamber 4, multiple high-purity gas cylinders, capacitance film vacuum gauge 6, primary sampling chamber 13, secondary sampling chamber Chamber 21, sampling chamber, small hole 22, calibration chamber 24, separation gauge 44 and air extraction system; wherein

[0039] The sample preparation chamber 4 is connected with the piston pressure gauge 2 and the capacitance film vacuum gauge 6 respectively, and the sample preparation chamber 4 is also connected with a plurality of high-purity gas cylinders connected in parallel through the fine-tuning valve 1; the sample preparation chamber 4 is connected with the A plurality of sampling chambers with different volumes are connected in parallel between the primary sampling chamber 13, and a plurality of sampling chambers with different volumes are connected in parallel between th...

Embodiment 2

[0049] In this embodiment, there are three sampling chambers connected in parallel between the sample preparation chamber 4 and the primary sampling chamber 13, and three sampling chambers connected in parallel between the primary sampling chamber 13 and the secondary sampling chamber 21, Specifically:

[0050] A new calibration device for partial pressure mass spectrometer, mainly composed of fine-tuning valve 1, piston pressure gauge 2, valve 3, 5, 7, 8, 11, 12, 14, 15, 18, 19, 20, 23, 25, 28, 30, 31, 32, 34, 35, 36, 38, 39, 40, 42, 43, sample preparation chamber 4, capacitance thin film vacuum gauge 6, first sampling chamber 9, second sampling chamber 10, primary sampling chamber 13. The fourth sampling chamber 16, the fifth sampling chamber 17, the second sampling chamber 21, the small hole 22, the calibration chamber 24, n high-purity gas cylinders 26, 27, 29, the third sampling chamber 33, the sixth sampling The chamber 37, the separation gauge 44, the first air extract...

Embodiment 3

[0062] In this embodiment, the gas to be configured is a mixed gas of He and Ar, and the volume ratio thereof is 1:4.

[0063] like figure 1 As shown, the novel partial pressure mass spectrometer calibration device designed by the present invention consists of a trim valve 1, a piston pressure gauge 2, valves 3, 5, 7, 8, 11, 12, 14, 15, 18, 19, 20, 23, 25 , 28, 30, 31, 32, 34, 35, 36, 38, 39, 40, 42, 43, sample preparation chamber 4, capacitance film vacuum gauge 6, first sampling chamber 9, second sampling chamber 10, primary Sampling chamber 13, fourth sampling chamber 16, fifth sampling chamber 17, secondary sampling chamber 21, small hole 22, calibration chamber 24, high-purity gas 26, 27, 29, third sampling chamber 33, sixth sampling The chamber 37, the calibrated pressure mass spectrometer 41, the separation gauge 44 and the like are composed.

[0064] In this embodiment, it is preferable to design or select each component as follows: the measurement accuracy of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com