Rotation driving force receiving head, driving force transfer component and processing box

A technology of driving force and receiving head, which is applied in electrography, optics, instruments, etc., can solve problems such as unstable printing, inconvenient drop-off, failure of the driving head of the developing box, etc., and achieve the effect of stable and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

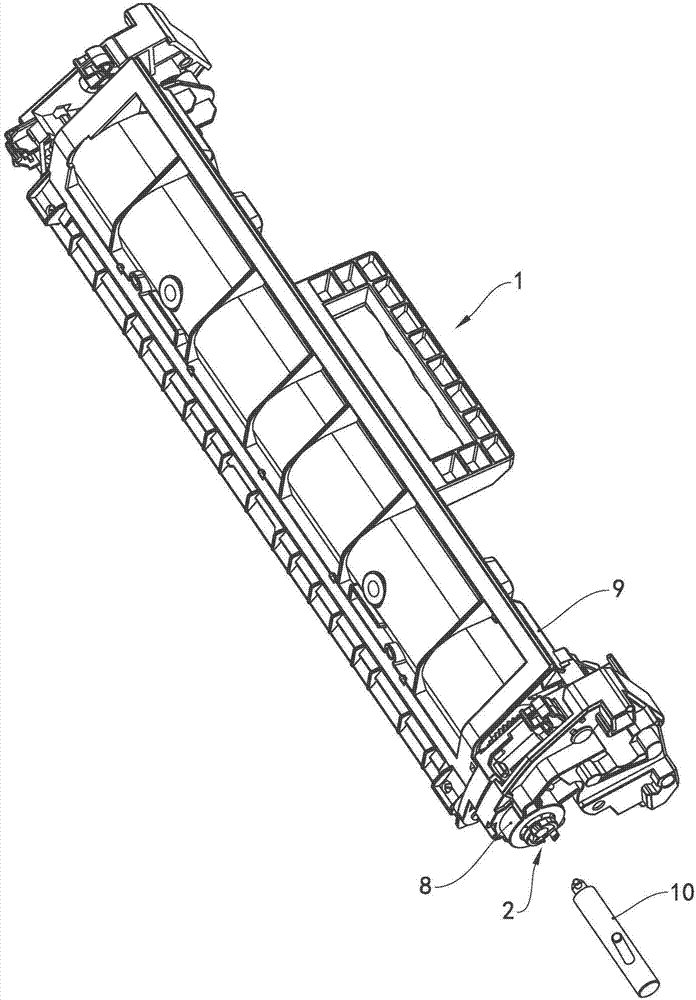

[0034] see figure 1 , figure 1It is a structural diagram of the processing box 1. The processing box 1 includes a powder bin 9, a roller (not marked) and a stirring frame (not marked) rotatably supported in the powder bin 9, and a driving force transmission assembly arranged at one end of the powder bin 9 2 and a limit mechanism 8 set on the driving gear of the driving force transmission assembly 2. In this embodiment, the roller is a developing roller, and the roller includes a roller body and a first driving force transmission device arranged on the axially outer end of the roller body. Components, the stirring frame is provided with a second driving force transmission part on the axial outer end, and the first driving force transmission part and the second driving force transmission part are respectively meshed with the driving force transmission assembly 2 through gears.

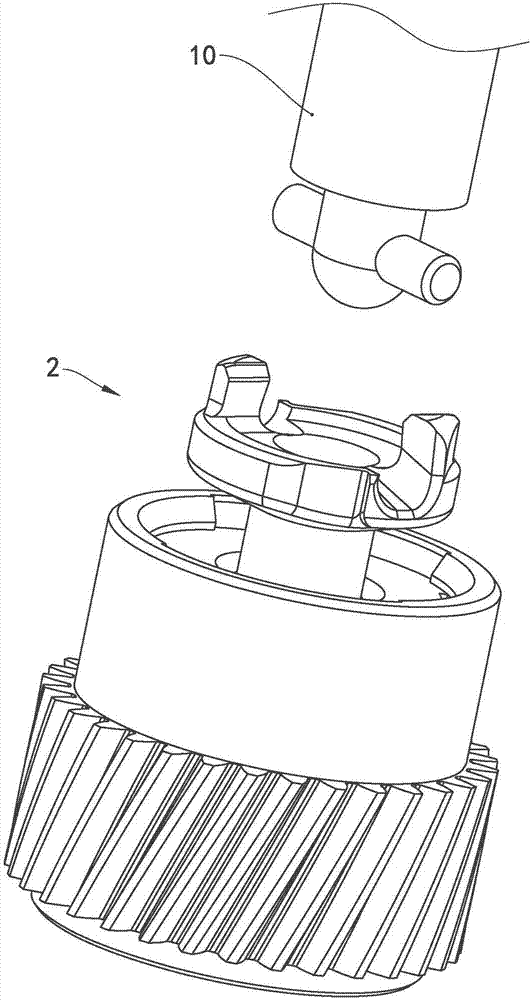

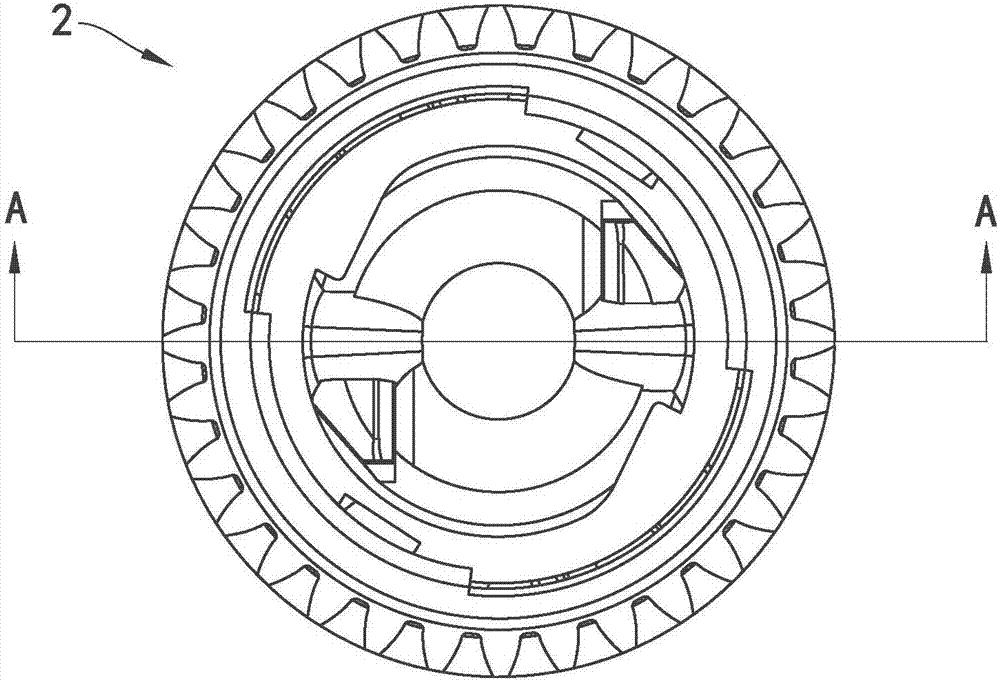

[0035] see Figure 2 to Figure 7 , showing the basic composition of the driving force transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com