DLP 3D printer beneficial to model releasing

A 3D printer, light curing technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of reduced printing efficiency, small force area, and easy to damage the bottom of the model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

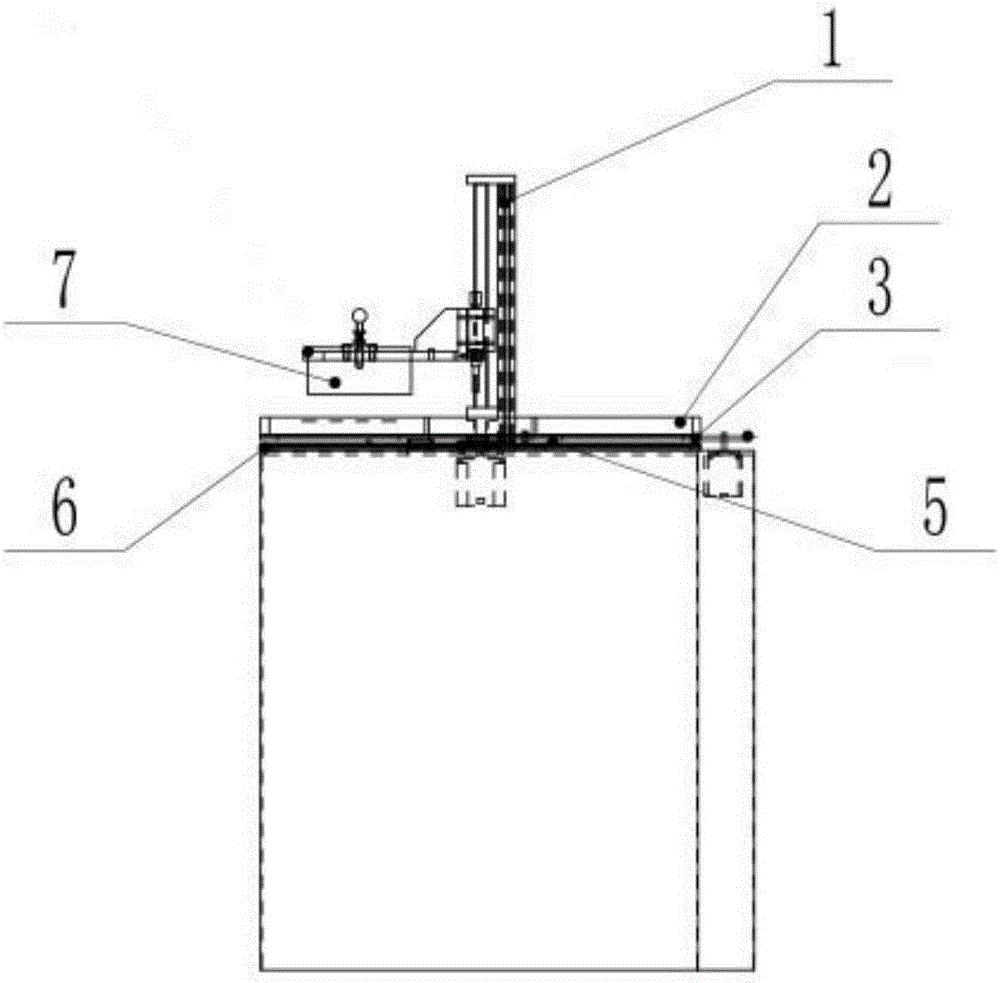

[0018] The DLP photocuring 3D printer that is convenient to demoulding of the present embodiment is as Figure 1-Figure 4 As shown, it includes a workbench 6, a vertical lifting mechanism 1, a projector light source (not shown in the figure) and a resin tank 2 fixed on the workbench 6. The projector light source faces the resin tank, and the bottom of the vertical lifting mechanism is fixed with The printing forming platform 7, wherein the vertical lifting mechanism 1 adopts a ball screw mechanism.

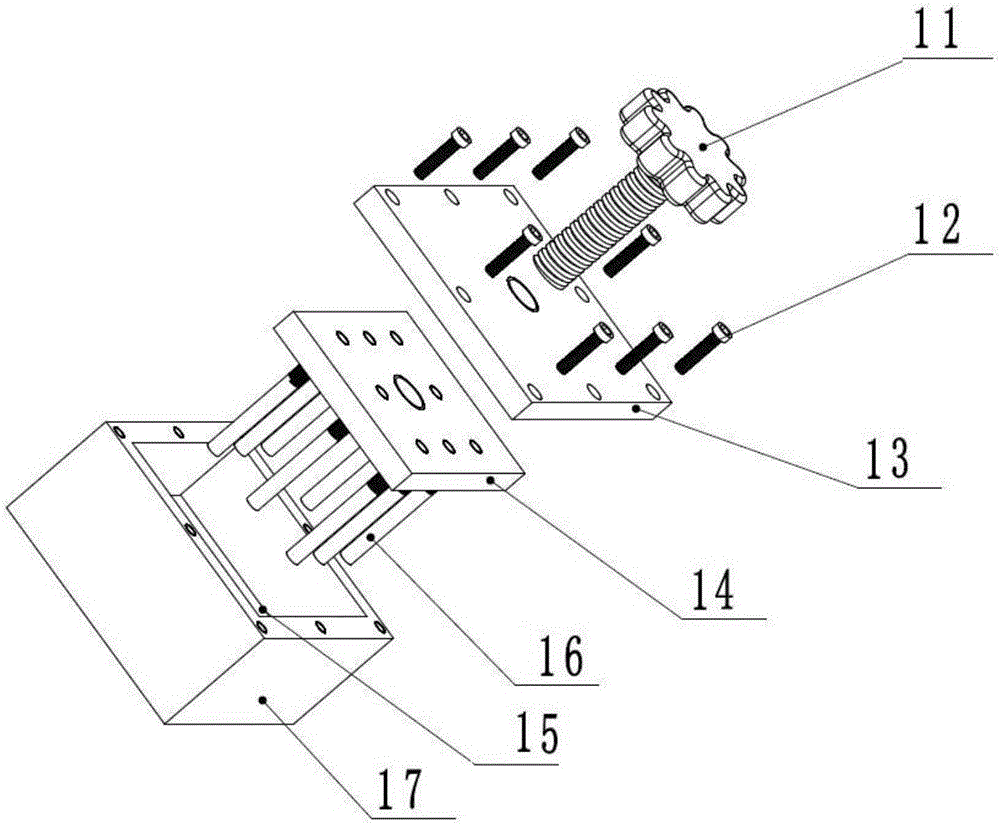

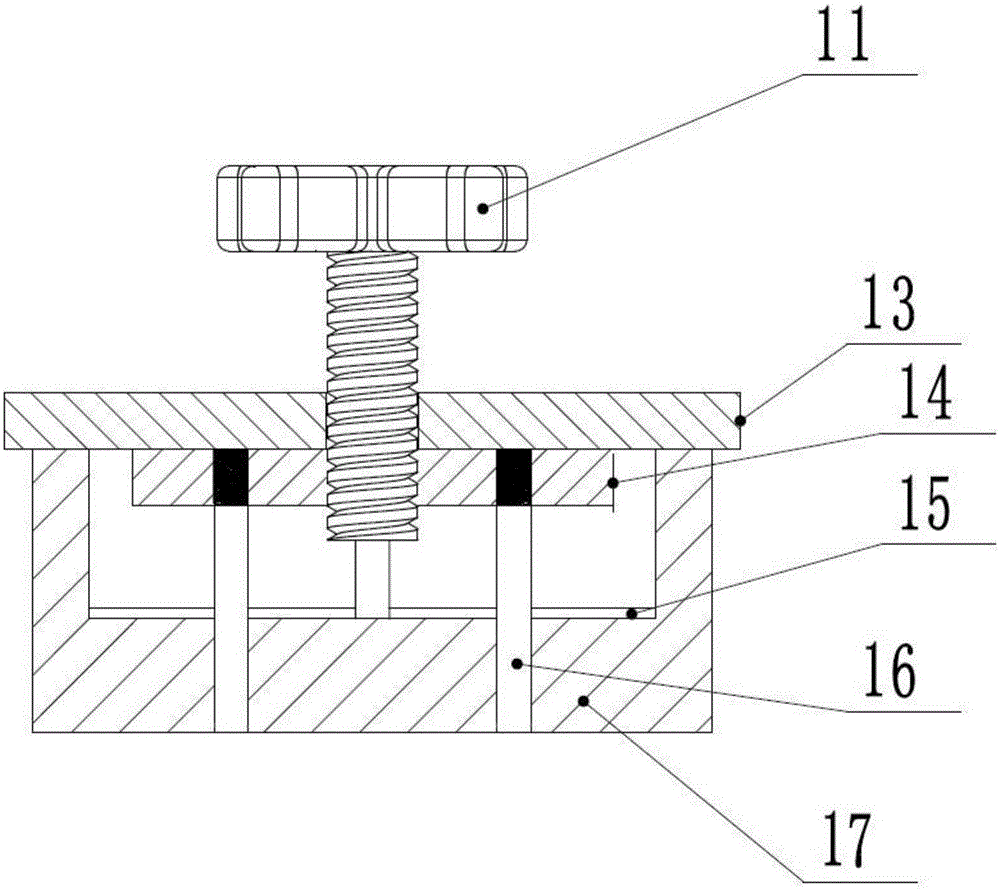

[0019] The printing forming platform 7 includes a handle 11, a push rod 16, a bottom plate 17, and a top plate 13 that is fixedly connected to the bottom plate 17 through the side plates. The bottom plate 17, the side plates, and the top plate 13 are combined to form a frame structure, and the bottom plate 17 and the side plates are integrally formed. The top plate 13 is fixedly connected to the side plates by fastening screws; the frame structure is provided with a fixed plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com