A vegetable hydroponic control system

A control system and vegetable water technology, applied in control/regulation systems, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problems of increased labor intensity of planters, inability to realize automatic operation, and reduce manual participation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

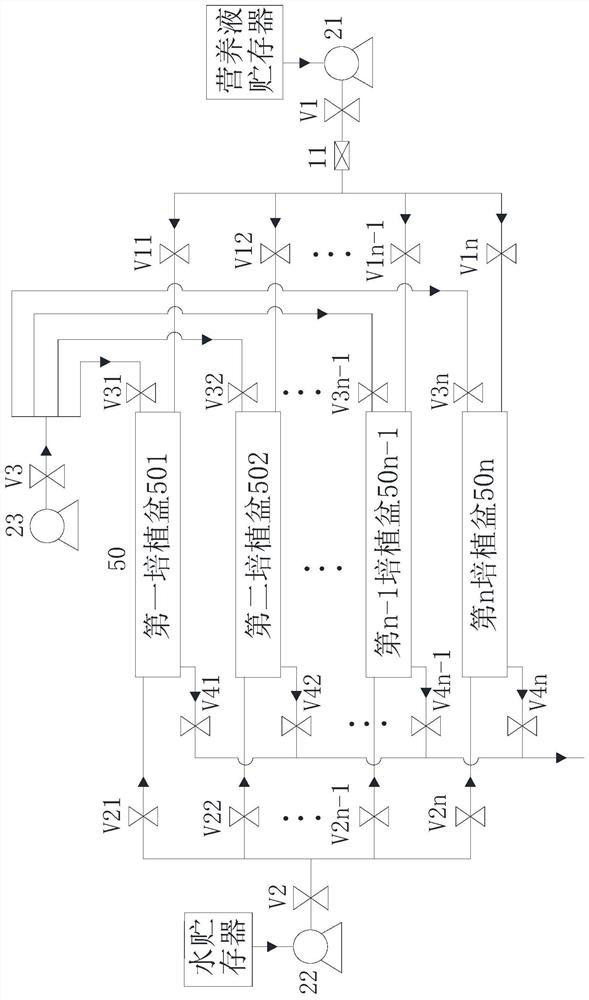

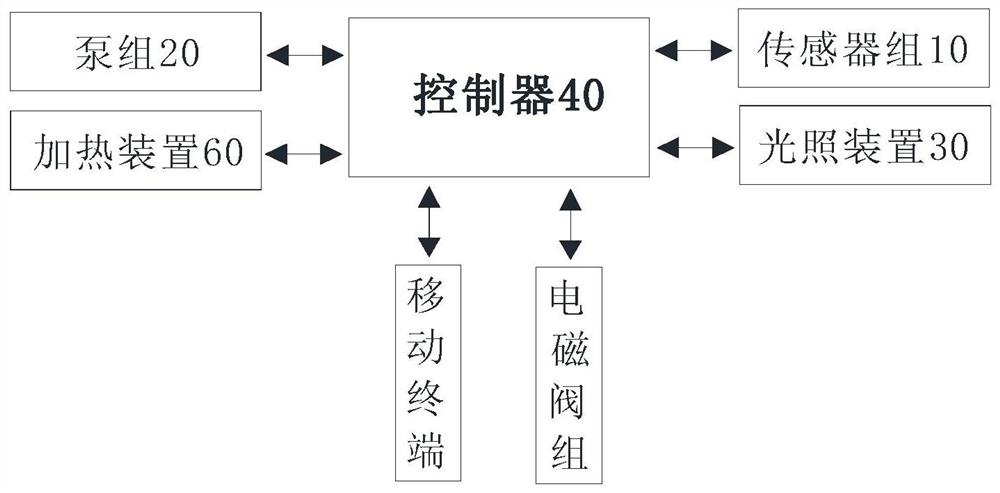

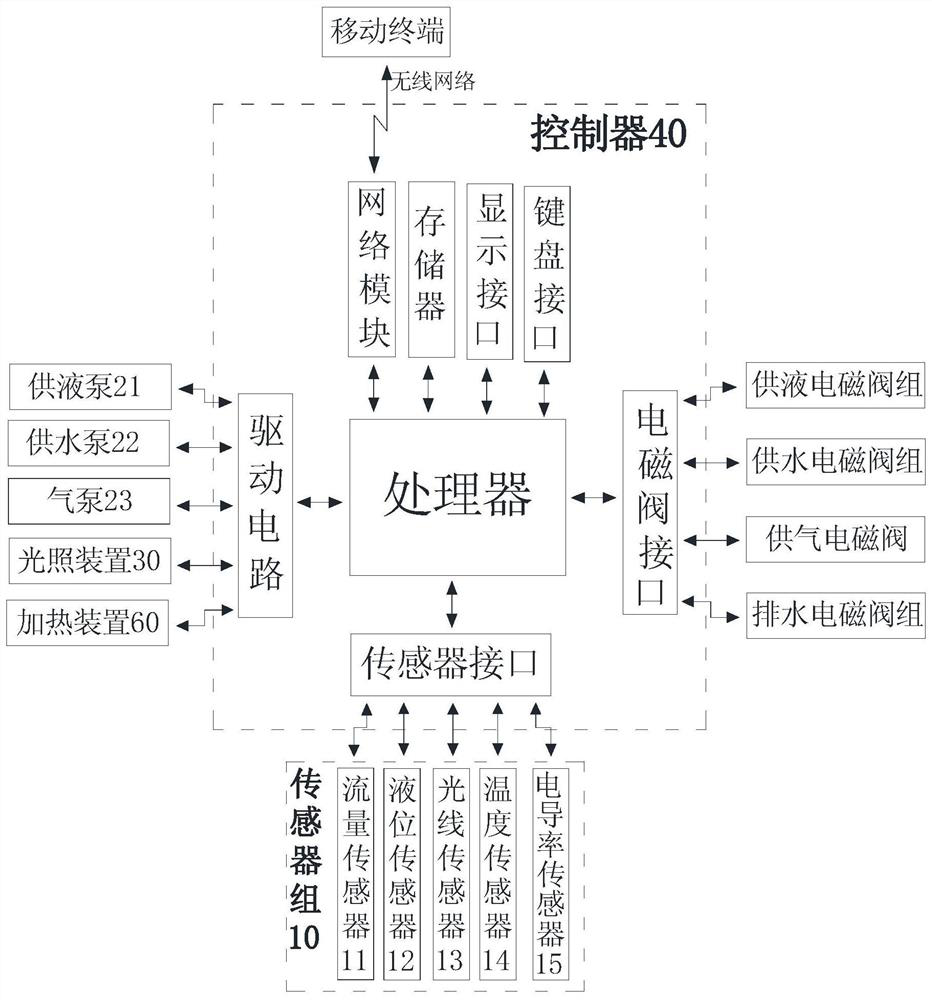

[0043] Vegetable hydroponics control system of the present invention, as Figure 1-Figure 3 As shown, the hydroponic control system includes a sensor group 10, a pump group 20, a solenoid valve group, a planting formula, a heating device, a controller 40, and corresponding cultivation pots 50 required for the implementation of the control system. The solenoid valve group includes a liquid supply solenoid valve group, a water supply solenoid valve group, an air supply solenoid valve group and a drain solenoid valve group. The technical scheme and control principle of the hydroponic control system of the present invention will take the control of three cultivation pots 50 as an example, that is, figure 1 n in takes a value of 3, which is describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com