Improved grinding device

An improved, electric connection technology, applied in the direction of coupling devices, parts of connecting devices, devices to prevent contact with live contacts, etc. The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

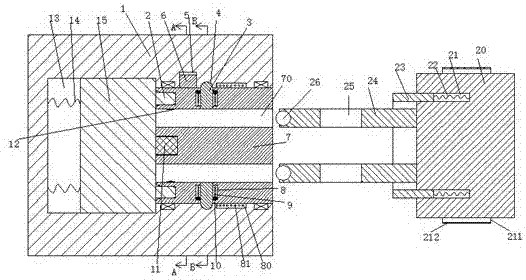

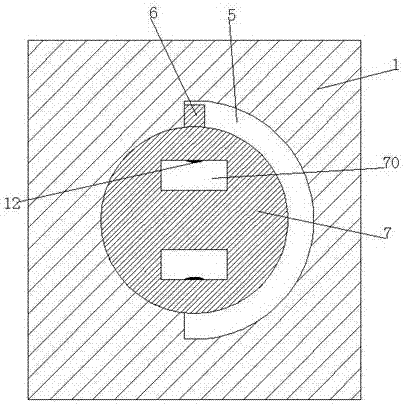

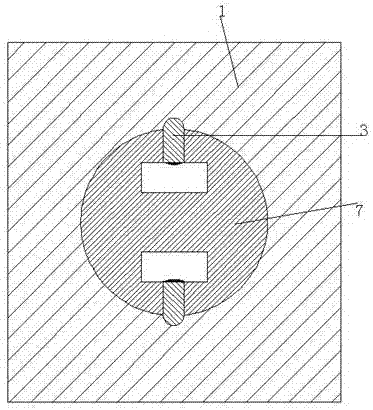

[0030] Combine below Figure 1-11 The present invention will be described in detail.

[0031] refer to Figure 1-11 , an improved grinding device according to an embodiment of the present invention, including an electrical coupling seat 1 and an electrical coupling head 20 connected to the grinding machine, and the electrical coupling head 20 is provided with a first annular groove 21 whose opening is towards the left end , a pipe sleeve 23 is movably installed in the first annular groove 21, and an electric connecting rod 24 located in the pipe sleeve 23 is correspondingly installed on the left end surface of the electric coupling head 20, and the electric connecting rod 24 There is a through groove 25 that penetrates up and down in the middle; the electrical joint head 20 is also provided with a hand grasping part, the hand grasping part includes a convex strip 211 and a rubber pad 212, and the electrical joint seat 1 is provided with a central groove , a twisting member 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com