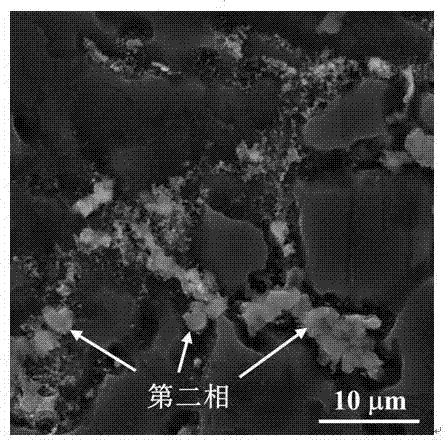

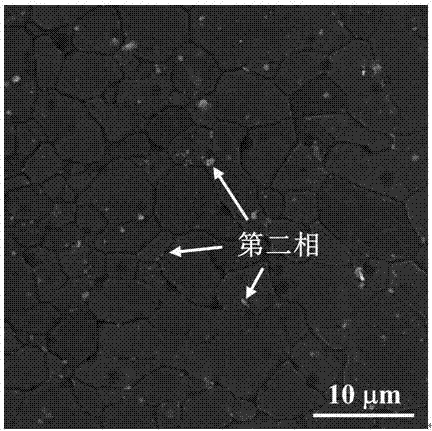

Predeformation auxiliary heat treatment and rolling method of high-volume-fraction second-phase magnesium alloy

A high volume fraction, magnesium alloy technology, applied in the direction of heat treatment process control, heat treatment furnace, metal rolling, etc., can solve the problems of difficult plastic processing and forming, and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

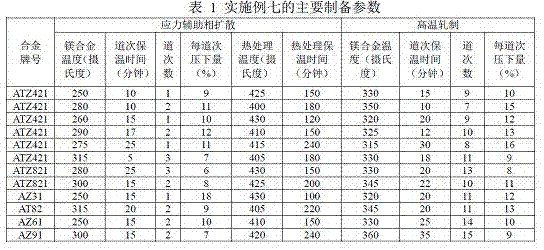

[0027] Example 1 Stress-assisted phase diffusion rolling method of high volume fraction second-phase magnesium alloy

[0028] 1) Stress-assisted phase diffusion: put the cast-rolled ATZ421 magnesium alloy billet into the heating box, and then perform one pass of pre-deformation rolling at 250 degrees Celsius for 10 minutes, with a reduction of 8%; then the pre-deformed magnesium The alloy is placed in a heating furnace, heated to 425 degrees Celsius for 150 minutes under the protection of argon, and the second phase is diffused by heat treatment;

[0029] 2) High-temperature rolling: the slab after the heat treatment in step (1) is rolled through more than 8 passes, the reduction of each pass is 10%, and the temperature is kept at 330 degrees Celsius for 15 minutes between each pass, and rolled into a thin plate. The total reduction is greater than 70%;

[0030] 3) Recrystallization treatment: place the rolled sample in a heating furnace, and perform annealing heat treatment ...

Embodiment 2

[0031] Example 2 Stress-assisted phase diffusion rolling method of high volume fraction second-phase magnesium alloy

[0032] 1) Stress-assisted phase diffusion: put the cast-rolled ATZ421 magnesium alloy billet into the heating box, and carry out 2 passes of pre-deformation rolling after holding it for 10 minutes at 280 degrees Celsius, and the reduction in each pass is 10%; then pre-deformed The final magnesium alloy is placed in a heating furnace, heated to 400 degrees Celsius for 180 minutes under the protection of argon, and the second phase is diffused by heat treatment;

[0033] 2) High-temperature rolling: the slab after the heat treatment in step (1) is rolled for more than 5 passes, the reduction of each pass is 15%, and the temperature is kept at 350 degrees Celsius for 10 minutes between each pass, and rolled into a thin plate. The total reduction is greater than 70%;

[0034] 3) Recrystallization treatment: place the rolled sample in a heating furnace, and perfor...

Embodiment 3

[0035] Example 3 Stress-assisted Phase Diffusion Rolling Method of High Volume Fraction Second Phase Magnesium Alloy

[0036] 1) Stress-assisted phase diffusion: put the cast-rolled AZ31 magnesium alloy billet into the heating box, and perform one pass of pre-deformation rolling after 15 minutes at 250 degrees Celsius, and the reduction of each pass is 20%; then the pre-deformation The final magnesium alloy is placed in a heating furnace, heated to 430 degrees Celsius for 100 minutes under the protection of argon, and the second phase is diffused by heat treatment;

[0037] 2) High-temperature rolling: the slab after the heat treatment in step (1) is rolled through more than 7 passes, the reduction of each pass is 12%, and the temperature is kept at 320 degrees Celsius for 20 minutes between each pass, and rolled into a thin plate. The total reduction is greater than 70%;

[0038] 3) Recrystallization treatment: place the rolled sample in a heating furnace, and perform anneal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com