Automatic production line material transmission abnormality monitoring method and automatic honing line

An automatic production line and material transfer technology, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of abnormal automatic line processing, affecting the operation of the production line, and wrong processing of workpieces, so as to eliminate the risk of wrong processing of workpieces and monitor the operation. Convenience and reliability, low upgrade cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

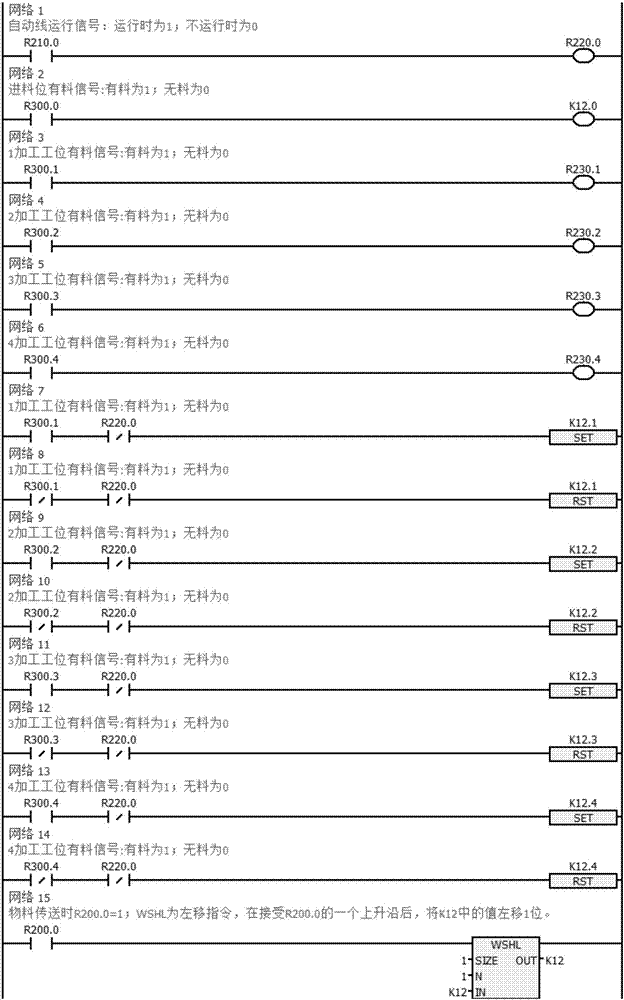

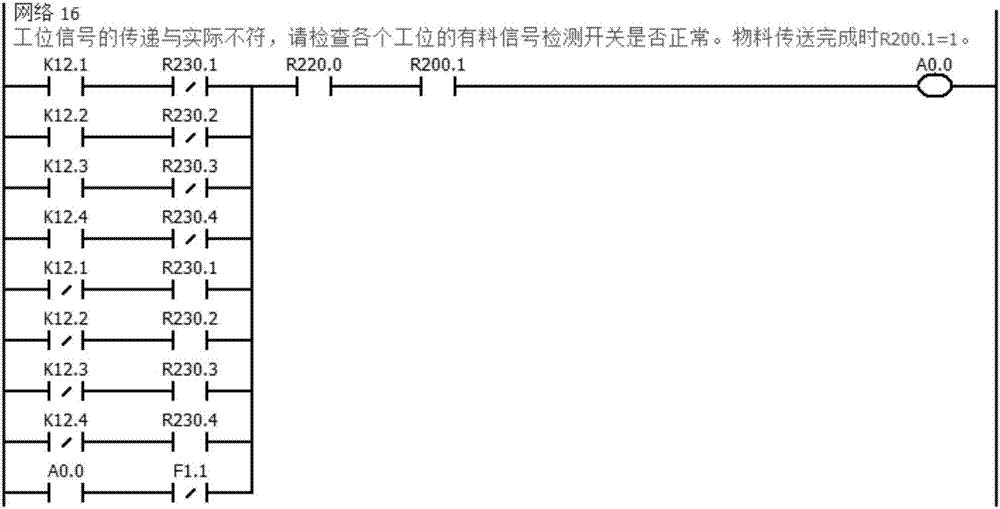

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The present invention is achieved in this way. The method for monitoring the abnormality of material transmission in the automatic production line includes the following steps: (1) setting byte variables K12.0-K12.n for the stations along the material transmission direction of the automatic production line, wherein n is a positive integer; (2) Assign 1 or 0 to the byte variable K12.0-K12.n according to whether there is a material on the station, where the byte variable assignment 1 indicates that the corresponding station has materials, and the byte variable assignment 0 indicates that the corresponding station has no Materials; (3) Automatic production line transmission shifts one station, the assignment of byte variables K12.0-K12.n is transmitted sequentially along the direction of automatic production line material transmission, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com