Rapid detection and locating platform

A positioning platform and fast technology, applied in the direction of measuring device, optical instrument testing, machine/structural component testing, etc., can solve the problem of slow positioning in manual measurement, and achieve the effects of various positioning methods, efficient positioning and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

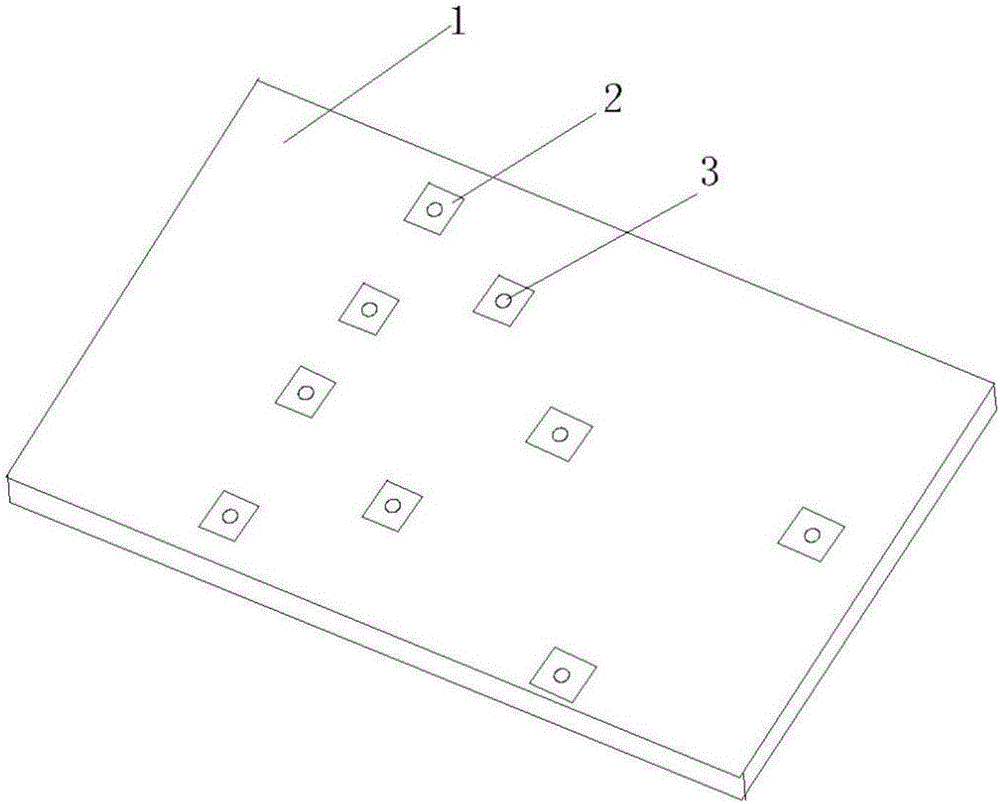

[0024] Such as figure 1 As shown, the detection and positioning platform of this embodiment includes a positioning platform 1 and a boss 2 located on the positioning platform. The boss 2 is provided with a threaded mounting hole 3. Three bosses form a group, and the number of boss groups can be three groups. , the lines connecting the centers of the three bosses in each group form an equilateral triangle, and the side lengths of the three formed equilateral triangles are different in size.

[0025] When positioning, the product to be tested having a through hole corresponding to the threaded mounting hole of the boss is installed on a group of bosses with an appropriate size in the positioning platform through bolts, and the positioning can be completed.

[0026] After the inspection work is completed, the fixing bolts are taken out, and the product to be inspected can be taken out, and the installation inspection of the next product is carried out.

Embodiment 2

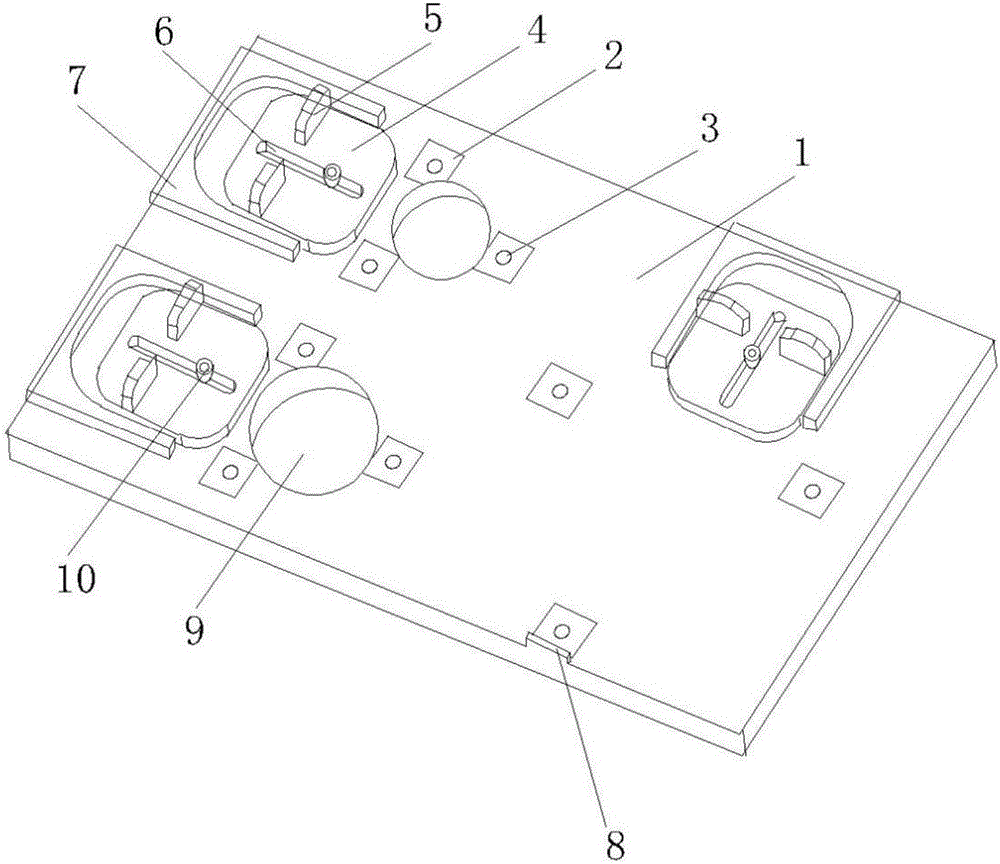

[0028] Such as figure 2 As shown, the detection and positioning platform of this embodiment also includes three positioning blocks 4 and three corresponding U-shaped chutes 7 on the basis of the first embodiment. The U-shaped chute 7 is matched, and the positioning block 4 is provided with a waist-shaped long through hole 6, and two threaded holes connected with the positioning block 4 are set on the positioning table 1, and the threaded holes are located at the sliding position of the waist-shaped long through hole 6. On the track, the positioning block 4 is connected to the positioning platform through the waist-shaped long through hole 6 using bolts. The tightness of the bolts ensures that the positioning block can slide back and forth in the U-shaped chute 7 on the positioning platform, and the bolt cap can ensure that the positioning block does not come out. U-shaped chute. The positioning block 4 may be provided with a hand-held block 5 for swinging the positioning blo...

Embodiment 3

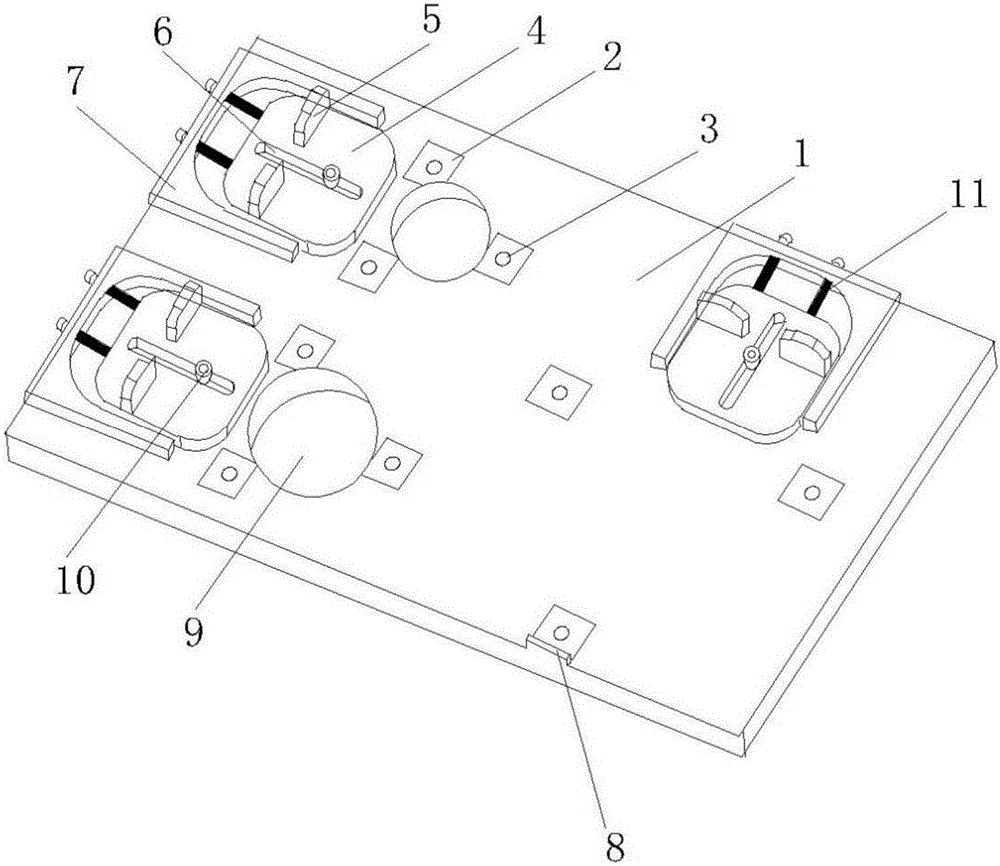

[0032] Such as image 3 As shown, the detection and positioning platform of this embodiment also includes a spring 11 and a bolt 13 on the basis of the second embodiment, the bottom end of the U-shaped chute 7 is provided with a through hole, and the positioning block 2 is provided with a The threaded hole 12 corresponding to the through hole, the bolt 13 passes through the through hole of the U-shaped chute, then passes through the inner hole of the spring 11, and finally directly connects to the threaded hole 12 of the positioning block 2.

[0033] The positioning block 2 is connected to the positioning platform through the slide rail bolt 13, and the slide rail bolt 13 is not fastened to ensure that the positioning block 2 can slide freely and smoothly in the U-shaped chute 7 of the positioning platform without falling out of the U-shaped chute 7, Such as Figure 5 As shown in the installation bolt-spring structure, the bolt passes through the through hole of the U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com