Lifting type concrete tank truck for steep inclined shaft transportation and lifting method thereof

A concrete and large-slope technology, applied in chemical instruments and methods, clay preparation equipment, cement mixing equipment, etc., can solve the problems that vehicles and tanks cannot operate independently, the vehicle body cannot drive to the construction site, and the concrete tank body cannot be hoisted, etc. Achieve the effect of flexible concrete transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

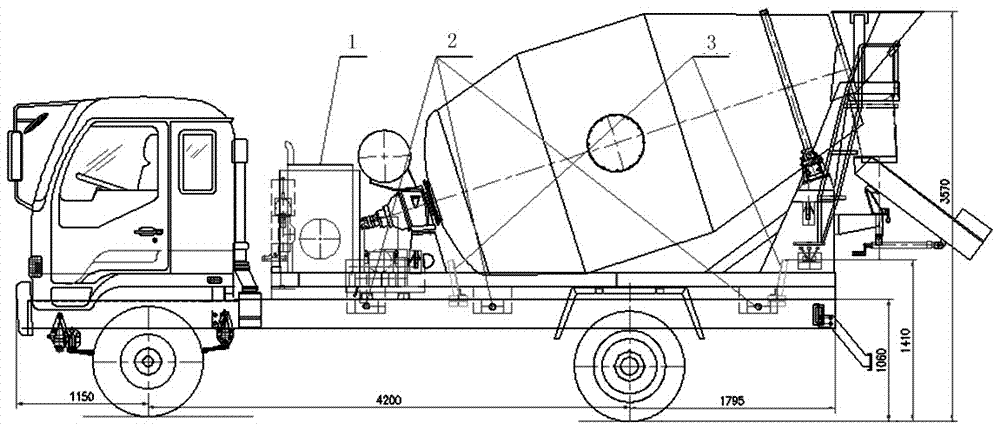

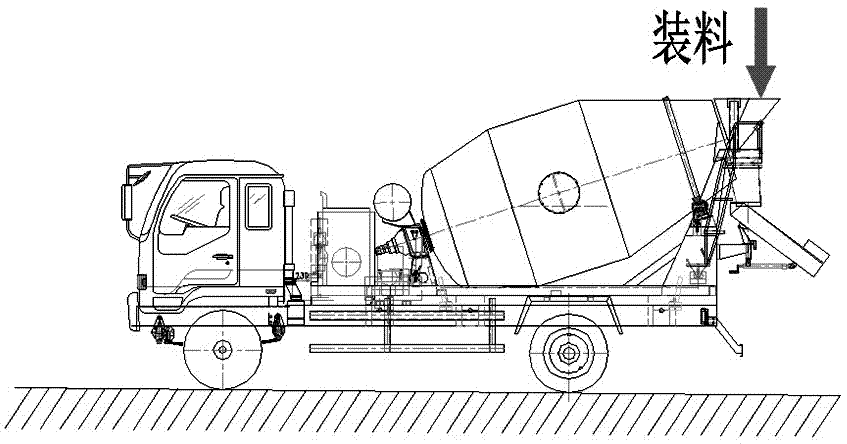

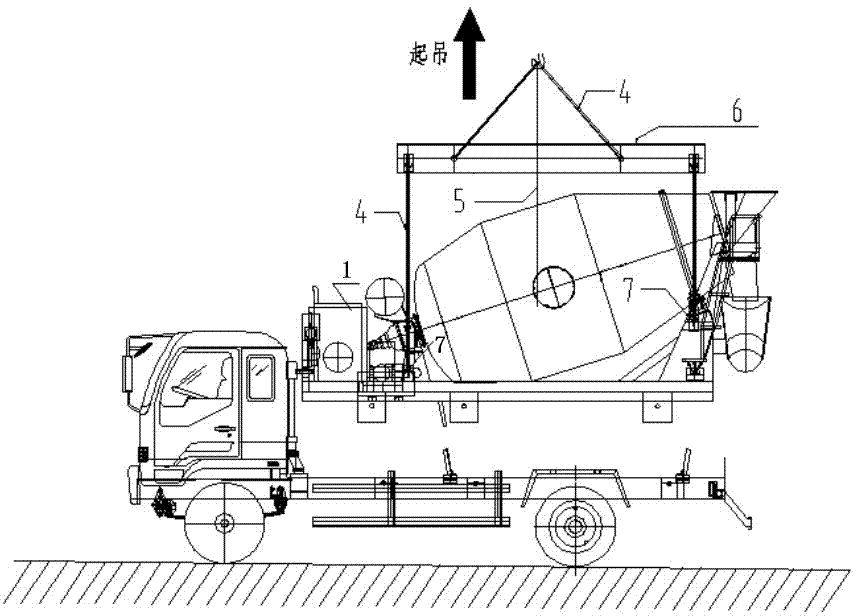

[0038] The LJ-11 bidding contract section of the Qinling Tiantai Mountain Extra-Long Tunnel of Baoping Expressway in Shaanxi Province is located at the source of the Jialing River. It is a control project for the entire line. The contract section is 3.185 kilometers long. The longitudinal slope of the 1# ventilation inclined shaft in the LJ-11 section of Baoping Expressway is -40.17%, and the length is 962 meters. The slag removal and material transportation of the inclined shaft are carried out by a 3.5-meter winch rail transportation system. The hoistable concrete tank car is full of materials, transported to the wellhead of the inclined shaft under the gantry crane, the gantry crane is lifted to realize the separation of the car and the concrete tank, and then transferred to the track flat car and transported to the bottom of the well. Then it is transferred and hoisted by the gantry crane at the bottom of the inclined shaft to the transport vehicle at the bottom of the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com