Automatic pencil feeding mechanism for pencil sharpener

A pencil sharpener and pen feeding technology, which is applied in the field of stationery, can solve the problems that affect the performance of the automatic pen feeding mechanism used in the pencil sharpener, easily occur vibration, and generate noise, etc., and achieve the effect of compact structure, reliable operation, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

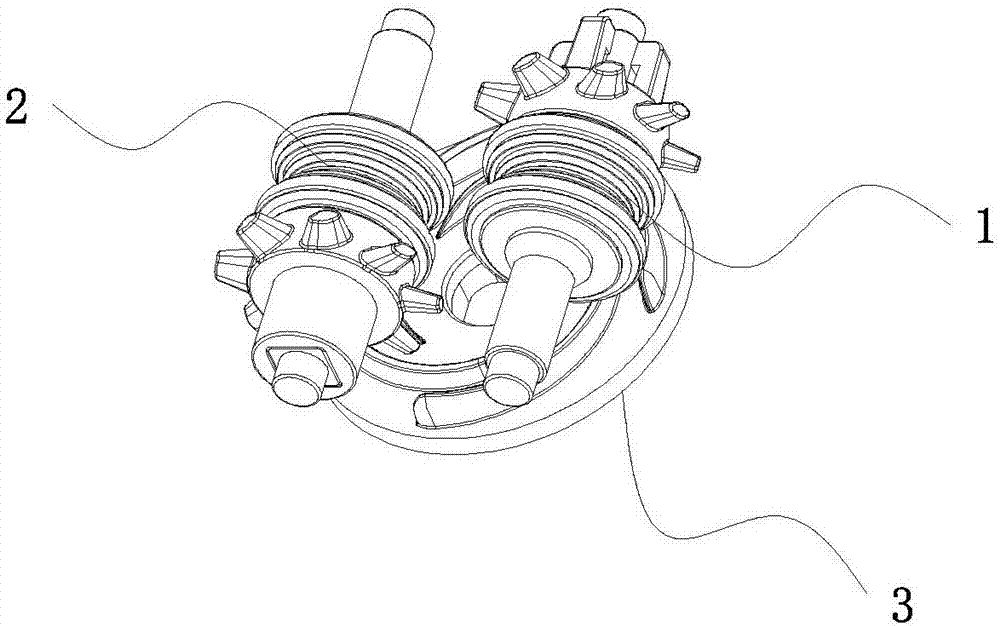

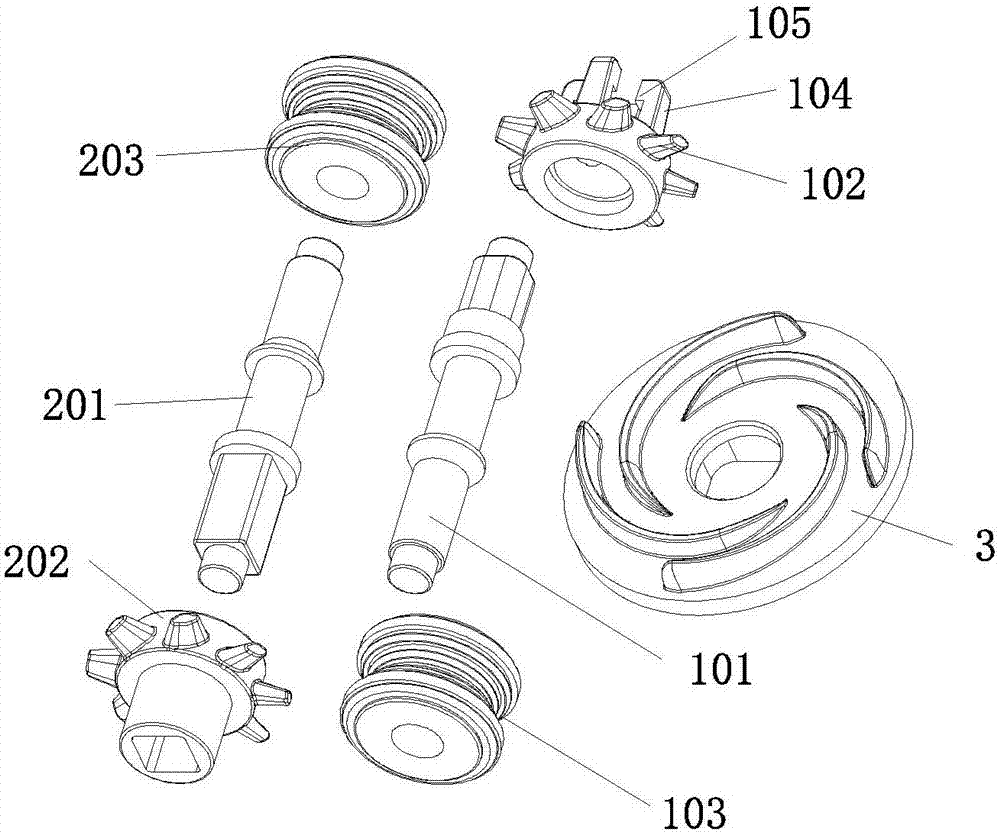

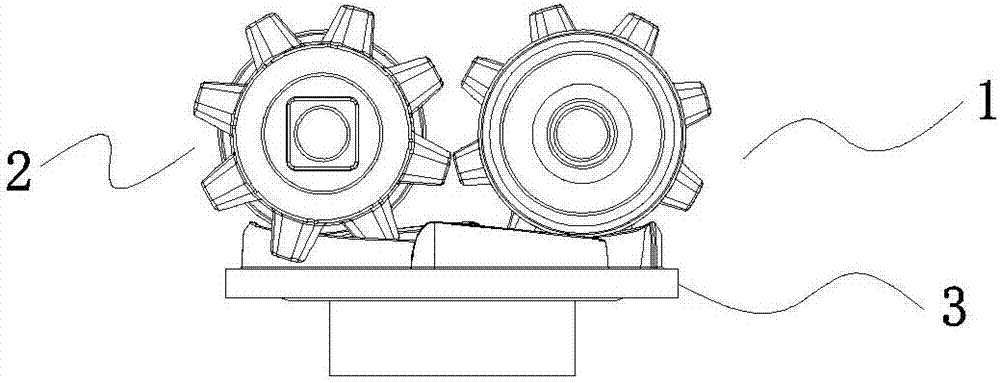

[0028] Such as Figure 1 to Figure 10 As shown, the automatic pen feed mechanism for the pencil sharpener of the present invention includes a turbine and a first pen feed assembly 1 and a second pen feed assembly 2 arranged parallel to each other; the first pen feed assembly 1 and / or the second pen feed assembly 2 The pen feeding assembly 2 includes an impeller, the turbine meshes with the impeller, and the rotation of the turbine drives the rotation of the impeller. In this specific embodiment, both the first pen feeding assembly 1 and the second pen feeding assembly 2 include impellers.

[0029] The first pen feed assembly 1 includes a first impeller shaft 101, a first impeller 102 and a first pen feed rubber roller 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com