Automatic mylar labeling machine

A labeling machine, automatic technology, applied in the direction of labeling machine, labeling, labeling, etc., can solve the problems of inability to realize the production process, high price of alternative models, and limitation of placement accuracy, and achieve high-precision and high-efficiency production, The transplanting process is fast and stable, and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

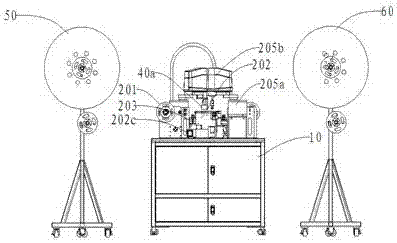

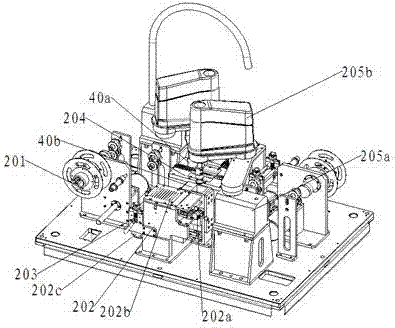

[0031] like Figure 1-3 As shown, a Mylar automatic labeling machine includes a frame 10, a labeling assembly and a feeding platform 30, the labeling assembly is installed on the frame 10, and the labeling assembly includes a roll material mechanism 201 and a label stripping mechanism 202 , a compression mechanism 203, a positioning module 204 and a robot module 205, the discharge port of the coil mechanism 201 is connected to the compression mechanism 203, and the compression mechanism 203 is arranged on the feed inlet of the stripping mechanism 202 , the discharge port of the stripping mechanism 202 is provided with a positioning platform 202a, and the top of the stripping mechanism 202 is provided with a vacuum adsorption platform 202b; the positioning module 204 is parallel to the stripping mechanism 202, and the positioning module 204 A lower positioning camera 40b is arranged between the label stripping mechanism 202, and the gap between the positioning module 204 and th...

Embodiment 2

[0033] This embodiment is on the basis of embodiment 1:

[0034] like figure 1 As shown, the automatic labeling machine also includes a feeding mechanism 50 and a receiving mechanism 60 , and the feeding mechanism 50 and the receiving mechanism 60 are respectively arranged on the left and right sides of the frame 10 .

Embodiment 3

[0036] This embodiment is on the basis of embodiment 1:

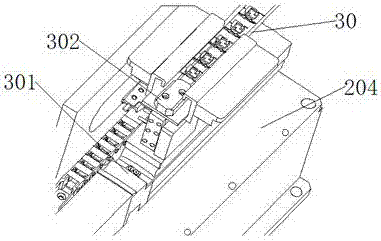

[0037] like image 3 As shown, the feeding platform 30 is provided with an electric cylinder 301 and a positioning pin 302 for controlling the stable movement of the electronic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com