Headstall with tension detecting function

A bridle and tension technology, which is applied in the direction of tension measurement, measurement, and parts of connecting devices, can solve the problems that tension detection equipment is not suitable for the internal environment of oil wells, and the value of tension sensors is expensive, so as to prevent damage to tension sensors and realize integration The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

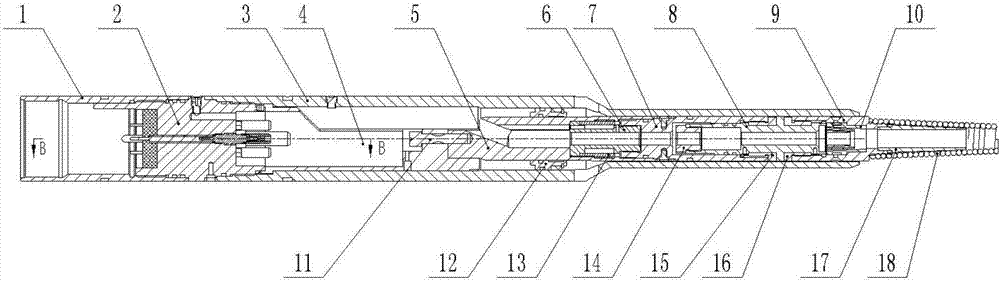

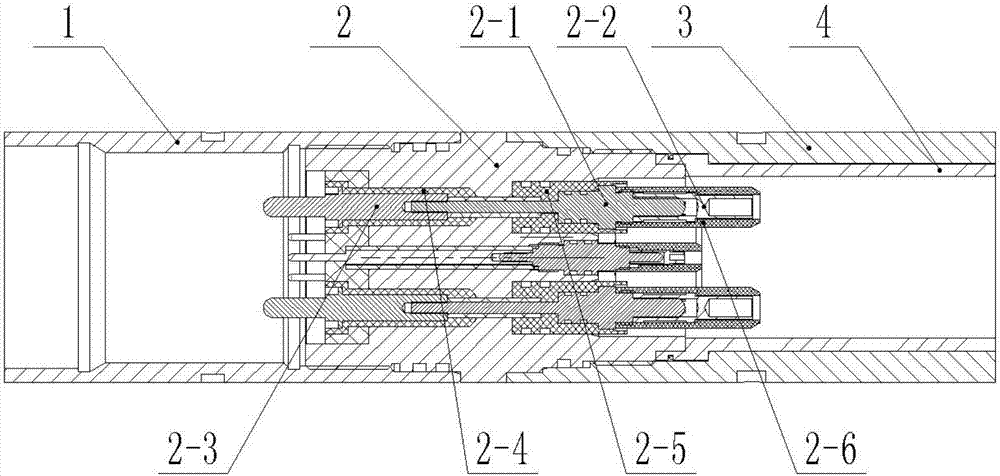

[0024] Combine below Figure 1-4 Describe this embodiment, a bridle with tension detection, including interface sleeve 1, pin joint 2, salvage cap shell 3, anti-rotation body 4, piston tube 5, tension sensor 6, tension connection sleeve 7, sealing body 8. Cone frame 9 and three-cone sleeve 10, the interface sleeve 1 is fixedly connected to the left end of the pin joint 2, the salvage cap shell 3 is fixedly connected to the right end of the pin joint 2, and the anti-rotation body 4 Snapped inside the fishing cap shell 3, the anti-rotation body 4 is located at the right end of the pin joint 2, the right end of the anti-rotation body 4 is fixedly connected to the piston tube 5, and the right end of the piston tube 5 is fixedly connected to the tension sensor 6 , the right end of the tension sensor 6 is fixedly connected to the tension connection sleeve 7, the right end of the tension connection sleeve 7 is connected to the sealing body 8, the right end of the sealing body 8 is co...

specific Embodiment approach 2

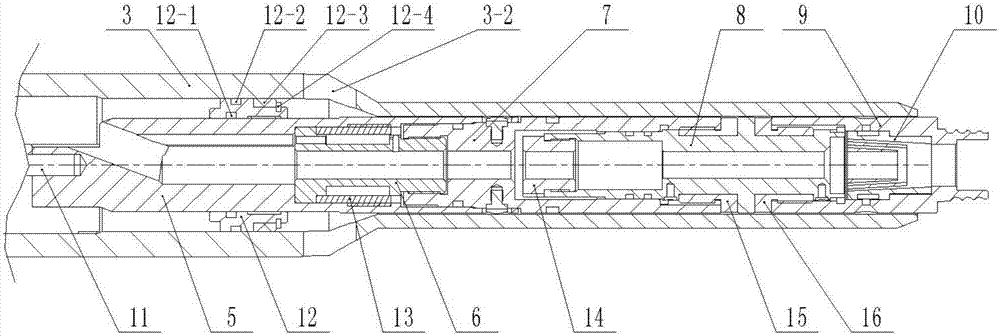

[0027] Combine below Figure 1-4 This embodiment will be described, and this embodiment will further describe Embodiment 1. A safety tension pin 11 is arranged between the anti-rotation body 4 and the piston tube 5, and one end of the safety tension pin 11 is connected to the anti-rotation body 4 by threads. The other end of the safety tension pin 11 is threadedly connected to the piston tube 5; the tensile force on the safety tension pin 11 is the same as that on the tension sensor 6, and when the tension on the safety tension pin 11 is too large, it is close to the limit of the cable tension Or when exceeding the detection range of the tension sensor 6, the safety tension pin 11 is broken due to being subjected to the ultimate tension force, so that the piston tube 5, the tension sensor 6, the tension connection sleeve 7, the sealing body 8, the cone frame 9 and the three-taper sleeve 10 are separated from the The salvage cap shell 3 slides out, and the piston tube 5, the te...

specific Embodiment approach 3

[0028] Combine below Figure 1-4Describe this embodiment, this embodiment will further explain Embodiment 1, the piston tube 5 is sleeved and connected to the balance piston 12, the balance piston 12 is slidably connected to the piston tube 5, and the balance piston 12 is provided with an inner seal Ring groove 12-1, outer sealing ring groove 12-2, sealing washer 12-3 and washer snap ring 12-4, the inner sealing ring groove 12-1 is provided with an inner sealing ring, and the outer sealing ring groove 12 -2 is provided with an outer sealing ring, the inner sealing ring is located between the balance piston 12 and the piston tube 5, the outer sealing ring is located between the balance piston 12 and the inner wall of the fishing cap shell 3, and the sealing gasket 12- 3 is socketed on the balance piston 12, the washer snap ring 12-4 is snapped on the balance piston 12, the sealing washer 12-3 is snapped between the balance piston 12 and the washer snap ring 12-4, the The seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com