Precision device for controlling flow rate of liquid and application method thereof

A precision device and liquid flow technology, which is applied to components of pumping devices for elastic fluids, pump control, liquid variable capacity machinery, etc., can solve uneven liquid delivery, unstable liquid flow speed, and overall equipment work Intermittent and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

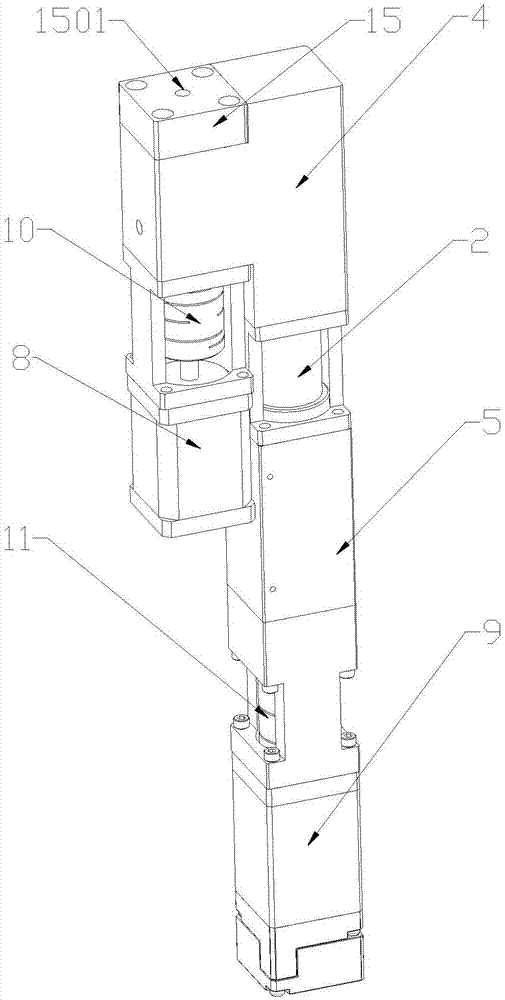

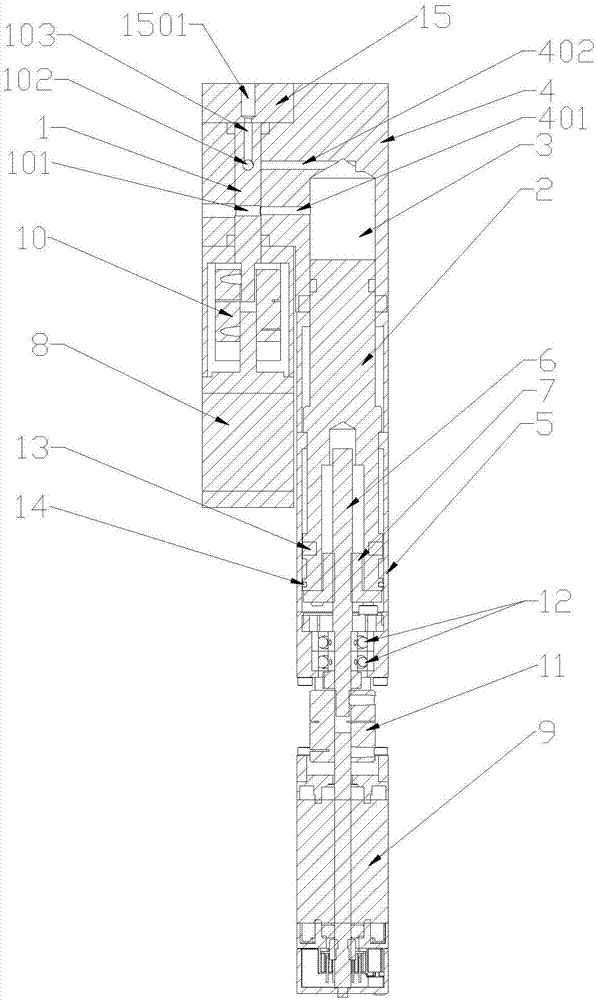

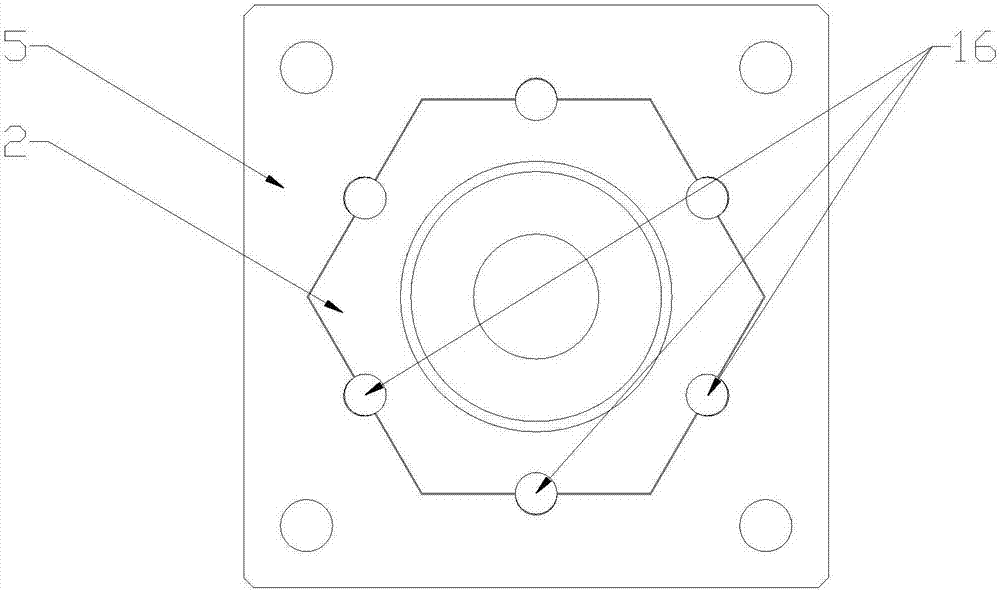

[0049] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0050] Such as Figure 1 to Figure 3 As shown, in this embodiment, a precision device for controlling liquid flow includes a first liquid driving assembly and a second liquid driving assembly, and the first liquid driving assembly includes a first driving member and a rotating central shaft 1 , the first driving member drives the rotary central shaft 1 to rotate, the side of the rotary central shaft 1 is provided with a first central hole 101 and a second central hole 102, the axis of the first central hole 101 Perpendicular to the axis of the second central hole 102, the rotary central shaft 1 is provided with a discharge hole 103, and the discharge hole 103 communicates with the second central hole 102; the second liquid drive assembly , including a second drive member, a piston head 2, a liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com