Grouting anchor rod construction process for supporting side slope

A technology of grouting bolts and construction technology, which is applied in basic structure engineering, construction, excavation, etc., can solve the problems of slope support safety hazards, affecting the effect of bolt support, and the cement slurry cannot be filled densely, etc., to achieve Reduce safety hazards, solve the decline in support effect, and reduce the effect of raw material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

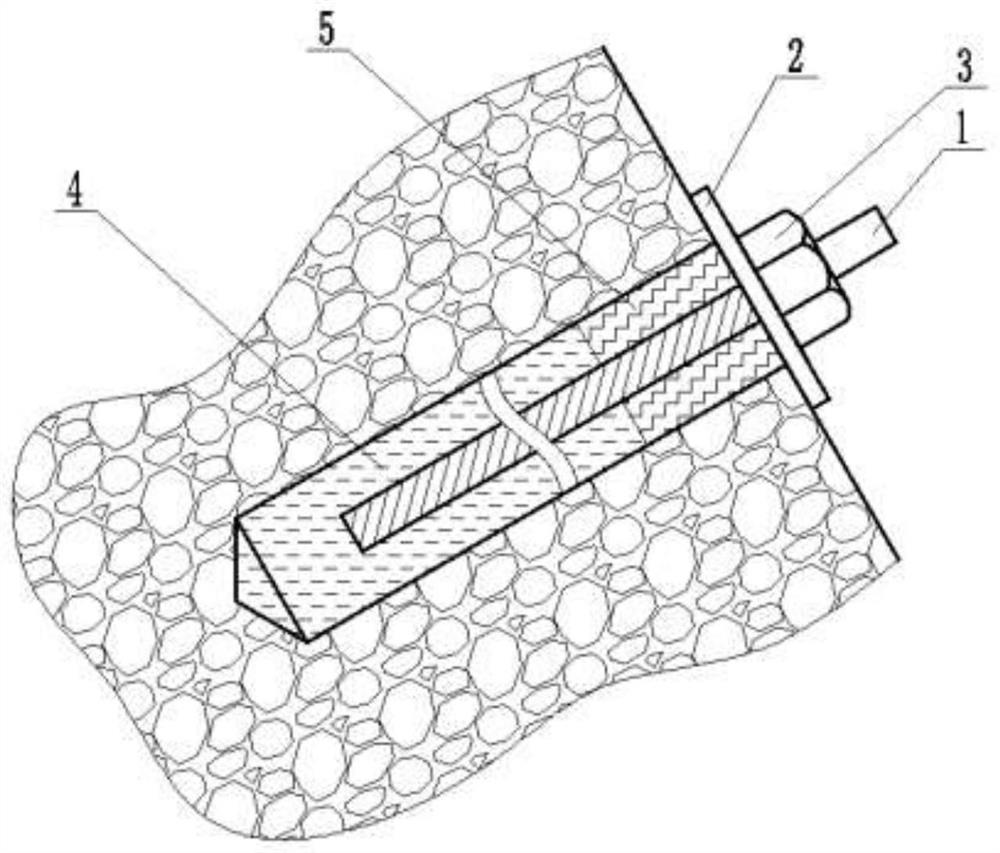

[0024] Such as figure 1 As shown, the present invention provides a kind of grouting bolt construction technique for supporting slope, comprising the following steps:

[0025] Step 1: Use the drilling machine to drill the anchor hole on the slope surface, and then send compressed air into the anchor hole to remove all sundries in the anchor hole through the compressed air, and then divide the anchor hole by From inside to outside, it is divided into front section 4 and back section 5; further, the drilling tool in step 1 is a hand drill. In step 1, the ratio of the lengths of the front section 4 to the back section 5 is more than 2:1. In step 1, the duration of removing all impurities in the anchor hole by compressed airflow shall not be less than 10 minutes.

[0026] Step 2: Provide a grouting machine, the grouting machine inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com